Excertos do catálogo

Stainless steels for springs and other demanding applications

Abrir o catálogo na página 1

Sandvik Group The Sandvik Group is a global high technology enterprise with around 300 subsidiary companies, 37,000 employees and activities in more than 130 countries. Sandvik’s operations are concentrated on its three core businesses of Materials Technology,Tooling and Mining and Construction – areas in which the group holds leading global positions in selected niche markets. Stainless strip and wire Sandvik Materials Technology Sandvik Materials Technology is a world-leading supplier of products with extensive added value in advanced metals, special alloys, metallic and ceramic...

Abrir o catálogo na página 2

Material for all types of springs and other demanding applications Springs and other details made of stainless strip and wire from Sandvik Materials Technology are used in applications ranging from products in our daily lives such as cars, telephones and computers to parts in medical, aerospace and other special purpose applications. Some springs will be exposed to millions of load cycles during service while others have to maintain a constant force for several years.They may have to work in corrosive environments, at high temperatures as well as in products where the material needs to be...

Abrir o catálogo na página 3

Material selection guide Sandvik grades Corrosion resistance Fatigue strength Sandvik S A F 2 5 0 7 As-delivered tensile strength Sandvik S A F 2 2 0 5 Sandvik Nanoflex Sandvik 1 1 R 5 1 / SAF 2205 Sandvik 9 RU 1 0 Sandvik Nanoflex Sandvik Sanicro 75X Sandvik Nanoflex Formability Elevated temperature Sandvik 9 RU 1 0 Sandvik Nanoflex Relaxation resistance Sandvik, SAF 2205, SAF 2507, Sanicro and Nanoflex are tr ademar ks owned by Sandvik AB . The perfor mance of our most impor tant gr ades for different proper ties is illustr ated above . Sandvik 12R10/12R11 is used as a base of compar...

Abrir o catálogo na página 4

A common requirement for spring applications is a material with high strength so that it does not become plastically deformed in service. For stainless steels this is achieved by cold working the material to the required tensile strength. The degree of cold work together with the chemical composition of the steel determines the tensile strength.This means that there is great flexibility in the combination of size and tensile strength that can be obtained. A less alloyed austenitic stainless steel will deformation harden more and it is therefore possible to reach a higher maximum strength. A...

Abrir o catálogo na página 5

Strip Stainless steel grade programmeChemical compositions, nominal, % Sandvik grade Standard designations 11 C Si Mn Cr Ni Mo Others SS EN ASTM UNS AUSTENITIC STAINLESS STEELS 12R11 0.10 1.2 1.3 16.5 7 - - 2331 1.4310 (301) (S30100) PRECIPITATION HARDENABLE STEELS 9RU10 0.08 0.5 0.9 16.5 7.5 - Al=1.0 2388 1.4568 631 S17700 DUPLEX STAINLESS STEELS Springflex2) <0.03 0.5 0.9 22 5.5 3.2 N=0.18 - - - S32205 NI-BASE ALLOYS Sanicro...

Abrir o catálogo na página 6

Sandvik grade Tensile strength Width Thickness AUSTENITIC STAINLESS STEELS 12R11 800-1900 2-345 0.015-3 PRECIPITATION HARDENABLE STEELS 9RU10 1200-1700 2-360 0.015-3 DUPLEX STAINLESS STEELS SAF 2205 800-1500 2-300 0.015-3.5 NI-BASE ALLOYS Sanicro 75X 750-1350 2-200 0.015-4 Sandvik stainless strip steels are manufactured in a wide range of sizes and tensile strengths.The available ranges for different grades in our standard production are shown in the table. Non standard requirements are often available on special request. It should be noted,...

Abrir o catálogo na página 7

Thickness tolerances Our cold rolling mills are equipped with automatic gauge control systems for continuous thickness measurement and adjustment for process control. This results in thickness tolerances superior to those given in EN 10258. On strip wider than 25 mm, the measuring point is at least 10 mm from the edge. For narrower strip the tolerance applies over the whole width of the strip. The standard tolerance class is T2. Width tolerances The width tolerances are in accordance with EN 10258 regarding total range, but with ±-tolerances around the nominal width instead of +-tolerances...

Abrir o catálogo na página 8

Shape tolerances Flatness Deviation from flatness in cold rolled strip is difficult to specify, because it can appear in a variety of forms. Crossbow, waviness and coil set are measurable -see illustration.These different forms can also act in combination. One form or the other will predominate, depending on the width, thickness and tensile strength of the strip. For strip less than 50 mm wide, deviation from flatness can be stated as crossbow in percentage of width or as coil set in mm/300 mm lengths. Both these properties can be measured with suitable instruments. The coil set is usually...

Abrir o catálogo na página 9

Round and flat wire Stainless steel grade programme Chemical compositions, nominal, % Sandvik grade Standard designations C Si Mn Cr Ni Mo Others SS EN/ISO ASTM JIS UNS AUSTENITIC STAINLESS STEELS 12R10 0.08 0.6 1.2 18 9 - - 2331 1.4310 302 SUS 302/ - PRECIPITATION HARDENABLE STEELS DUPLEX STAINLESS STEELS SAF 2205 0.020 0.4 1.5 22 5.5 3.0 N=0.17 2377 1.4462 - - S31803 NI-BASE ALLOYS Sanicro 75X 0.030 0.3 0.5 16 72 - - - - - - N07750 ')For better cold formability the upper limit...

Abrir o catálogo na página 10

Flat rolled wire Sizes Flat rolled wire is available in widths from 0.5-7.0 mm and thicknesses from 0.054.00 mm and with round or sharp rolled edges. Other strength levels can be supplied on request. In the cold rolled condition. Wire diameter Distance Archeight in Coil Coil mm L, mm centre H, mm ID, mm weight, kg Round wire The tolerances below are standard. Closer tolerances can be supplied on request. Ovality is according to the standard EN 10270-3. The tolerances for roundness, i.e. the difference between the largest and smallest diameter in the same cross-section...

Abrir o catálogo na página 11Todos os catálogos e folhetos técnicos SANDVIK MATERIALS TECHNOLOGY

-

Strip steel for edge applications

8 Páginas

-

SANDVIK ROCK DRILL STEEL

4 Páginas

-

STAINLESS STEELS FOR MACHINING

29 Páginas

-

AquaSan Ni50

2 Páginas

-

APM 9980

4 Páginas

-

APM 2723

5 Páginas

-

APM 2377, UNS S31803

4 Páginas

-

APM 2354, UNS S31603

3 Páginas

-

APM 2327, UNS S32505

4 Páginas

-

Sandvik precision strip steel

16 Páginas

-

SANMAC 4571

10 Páginas

-

Sandvik billets and blooms

10 Páginas

-

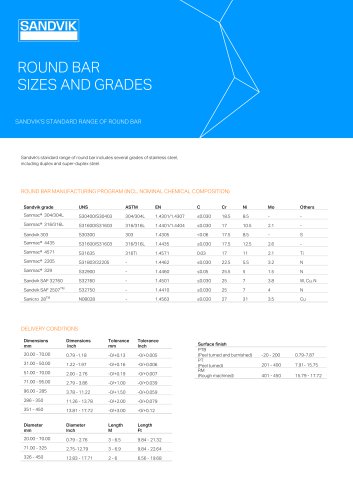

ROUND BAR SIZES AND GRADES

4 Páginas

-

Sanmac®329

2 Páginas