Excertos do catálogo

Con verging of Global Resources Profe ssional as Industry Leader Website: www.conprofecnc.com E-mail: Address: No.6, 2nd Nanyun Road, Science City, Hi-tech Development Zone, Guangzhou, 510663, P.R.C 2024 Conprofe Technology Group Co., Ltd. All Rights Reserved. VE1.0 The information given is not binding. Actual products and mutual agreement shall prevail. Reprinting of any text and illustrations requires written authorization of Conprofe. Professional Manufacturer of Ultrasonic Equipment and High-Performance Tools

Abrir o catálogo na página 1

About Conprofe Company Overview Manufacturing and Testing Equipment Innovative Minimum Quantity Lubrication System Product Introduction Airlube Series

Abrir o catálogo na página 2

About Conprofe About Conprofe Company Overview With its roots back to 2003, Conprofe is a Provider of Efficient, Green and Intelligent Manufacturing Solutions and Key Units. It has been holding on to the idea of “Converging of Global Resources, Professional as Industry Leader” in the past two decades. Revolving around "Efficient, Green and Intelligent Manufacturing”, the company has achieved a giant leap from parts, units to machines and developed a product portfolio with three major industries - Precision Tools, Key Units and CNC Machine Tools, which covers eight categories of products,...

Abrir o catálogo na página 3

Manufacturing and Testing Equipment Provider of Efficient, Green,Intelligent Manufacturing Solutions and Key Units Minimum Quantity Lubrication (MQL) Cooling System

Abrir o catálogo na página 4

Minimum Quantity Lubrication System Provider of Efficient, Green,Intelligent Manufacturing Solutions and Key Units Benefits of MQL Cooling System MQL Cooling System R&D MQL offers numerous benefits that directly address issues associated with use of traditional cutting fluid. Drawing on over a decade of experience in metals machining and R&D of cutting tools, Conprofe has developed Longer Tool life Minimum Quantity Lubrication (MQL) System that enables highly efficient machining operations. We have also designed Extending tool life by virtue of higher cooling and a range of specialized...

Abrir o catálogo na página 5

Product Introduction - MQL Cooling System MQL Cooling System - Product Introduction Airlube MEM201 Features Adapted with Oil-Water Atomization Technology and equipped with dedicated Oil-Water Nozzle, forming a thin-layer of oil film mixed with water droplets to enable mixed atomization State-of-the-Art Oil-Water Ratio Regulating System to enable precise digitalized fine tuning of the amount of water and oil State-of-the-Art Precision Electric Pump with up to 1ml/h of tuning accuracy State-of-the-Art dedicated nozzles to User-friendly with compact structure, With function of alarming and...

Abrir o catálogo na página 6

Product Introduction - Airlube Series Airlube Series - Product Introduction Airlube Series MEM101 MQL Cooling System Airlube Series »> Working Principle ■ Dedicated nozzles generate an optimal mist for the cutting zone. Lubricant is efficiently atomized, creating micron-sized suspended particles that travel with compressed gas to the cutting zone. This forms a protective oil film between the cutting tool and workpiece, ensuring smooth and efficient cutting while minimizing wear and friction. ■ Customizable nozzles and premium micro-lubricants deliver tailored micro-lubrication and cooling...

Abrir o catálogo na página 7

Product Introduction - Airlube Series Airlube Series - Product Introduction Airlube Series Airlube Series Airlube MEM102 System features functions of Liquid Airlube MEM201, an efficiency-boosted oil-water MQL Level Alarm, Air Pressure Alarm, Power Prompt and equipment, applies new oil-water atomization technology Startup Prompt, etc., improving automation capability. and specially-engineered oil-water nozzle, allowing formation of Oil on Water (OoW) particle on the nozzle outlet, while With special system hardware and optical dedicated oil, water and gas are delivered separately to the...

Abrir o catálogo na página 8

Product Introduction - Airlube Series Airlube Series - Product Introduction Airlube MEM101 Airlube MEM102 Airlube MEM201 Note: ✓ Excellent • Good o Optional x Not recommended

Abrir o catálogo na página 9

Product Introduction - Airlube Pro Series Airlube Pro Series - Product Introduction Airlube Pro Series MIM101 MQL Cooling SystemAirlube Pro Series »> Working Principle ■ Spindle-Through MQL Cooling Technology facilitates seamless lubrication between the tool and the workpiece by leveraging highly dispersed micron aerosol transported by compressed air. The magic begins in the atomizing box of the micro-lubrication system, where the aerosol is generated. It is then introduced into the cutting tool through the rotating spindle of the machine tool, either exiting through the internal cooling...

Abrir o catálogo na página 10

Product Introduction - Airlube Pro Series Airlube Pro Series - Product Introduction MIS101 MQL Cooling SystemAirlube Pro Series »> ■ The MIS101 is a semi-automatic controlled Spindle-Through MQL Cooling System, suitable for machining where varying atomization levels are required for lubrication. ■ MIS101 atomizing box is equipped with a number of special atomizing devices and gas regulating valves, and through the combination of solenoid valve control, to achieve 5 kinds of flow regulation. ■ The MIS101 oil mist output is controlled by a ball valve, which is set near the spindle or add-on...

Abrir o catálogo na página 11

■L Product Introduction - Airlube Pro Series Accessories Set - Product Introduction Technical Data Note: Refer to the specific mahcining process • Standard o Optional Conprofe is proud to offer a comprehensive range of atomizing nozzles and common nozzles, designed to deliver exceptional blasting accuracy, uniform jet distribution, and minimal oil mist generation. Our blasting nozzles are characterized by their efficient "blasting mode”, ensuring optimal performance in various applications. Our diverse portfolio of nozzles caters to numerous industries and needs, providing tailored...

Abrir o catálogo na página 12

Product Introduction - Accessories Set Accessories Set - Product Introduction With unique ferrule design to ensure that uniform the oil jet applies stably and accuratly onto the cutting edge The atomizer oil mist outlet is close to the cutting edge, and the strong oil mist airflow can quickly remove the chips generated during the cutting process. Applicable to tool cooling and lubrication in turning, milling, drilling, tapping and other The powerful oil mist outlet is designed with Oil mist of suspended micro droplets generated by three-level identical-axis nozzle machining processes...

Abrir o catálogo na página 13Todos os catálogos e folhetos técnicos Conprofe Technology Group Co.

-

Conprofe 5-Axis Gantry Machining Centers

10 Páginas

-

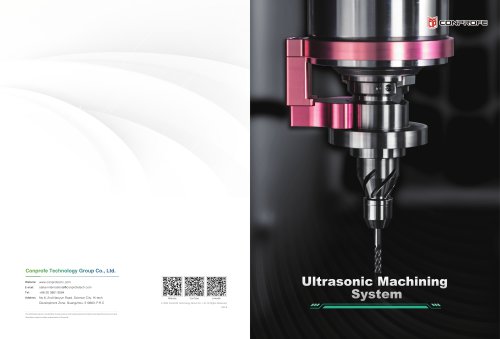

Ultrasonic Machining System

12 Páginas

-

PCD Cutting Tools

14 Páginas

-

Handheld Ultrasonic Pneumatic Drill

2 Páginas

-

Tapping Tools

38 Páginas

-

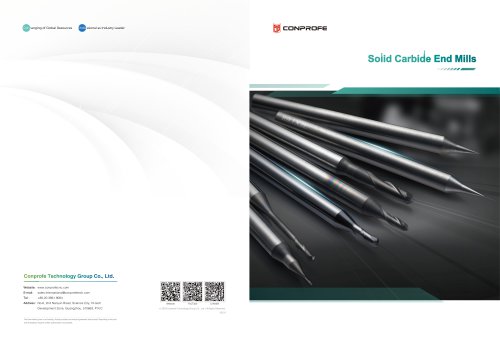

Solid Carbide End Mills

7 Páginas

-

Ultrasonic-Green Machine Tools

119 Páginas