Catalog excerpts

Product Information ZwickRoell Vibrophore 250 Range of applications The ZwickRoell Vibrophore represents the latest genera‐ tion of high-frequency pulsators, combining for the first time an electro-magnetically excited dynamic testing machine with a fully functional static materials testing machine. This is made possible by the 'two in one' function developed by ZwickRoell. Advantages and features • fully functional static and dynamic testing machine with stiff four-column load frame • high test-frequencies, giving short test times and high specimen throughput • easy to operate via testXpert III and testXpert Research test programs matched exactly to the testing situations • resonance drive has very low energy consumption (only around 2% of that of servo-hydraulic testing machines) • easy to install - no ancillary units or systems (e.g. hydraulics, coolant) needed • maintenance-free system - wear-free components • clamping table at convenient working height for oper‐ ator-friendly testing • remote control with color display showing measure‐ ment channels, machine and test status; also used for machine set-up • testControl II digital measurement and control elec‐ tronics with 10kHz control frequency and 24-bit reso‐ lution • continuously controlled servo motor for fast, accurate mean force control • pulse-width modulation for high control stability and low failure liability • easy test-frequency change simply by varying weights. • large range of standard tools and fixtures As well as being employed for quasi-static tensile and compression tests, Vibrophores are used in particular for determination of fatigue strength with regard to fatigue life and fatigue limit. This allows highly efficient fatigue testing, for example to DIN 50100 (S-N curve), with tensile, compression, pulsating and alternating loads. Other typical applications include fatigue tests on components (e.g. connecting rods, crankshafts, chains and threaded connectors) and standard metal speci‐ mens, together with fracture mechanics investigations on CT and SEB specimens, All tests can be force, displacement or strain-controlled, while with the addition of appropriate devices testing can also be carried out under various environmental conditions (e.g. temperature, aggressive media), toget

Open the catalog to page 1

Product Information ZwickRoell Vibrophore 250 Technical data Description Fmax Mean load max. Force amplitude max. Specimen elastic strain (oscillation displacement) max. Test frequency range1) No. of frequency steps2) No. of guide columns No. of lead-screw drives Frame stiffness at 1000mm crosshead separation 3) Drive Static tests and for mean force control min. crosshead speed max. crosshead speed max. crosshead return speed repeat positioning accuracy on crosshead motor holding brake Dynamic tests Load-frame dimensions H4 - height H3 - clamping-table height H2 - test area height H5 - test...

Open the catalog to page 2

testControl II measurement and control electronics Control frequency Measured-value acquisition Slots PC interface Integrated safety concept Display-equipped remote control unit Dimensions, testControl II measurement and control H1-height without table plate B1-width Approx. weight Length of cable Vibrophore - testControl II Accessories Universal measurement amplifier (029443) 10 kHz 10 kHz, 24 bits, arithmetical 5 x module bus (2 occupied as default) GigaBit Ethernet 2-channel specification for maximum safety interface for interlocked safety doors interface for Emergency STOP loop set-up...

Open the catalog to page 3All ZWICK GMBH & CO. KG catalogs and technical brochures

-

HC Series

2 Pages

-

HB series

3 Pages

-

Vibrophore 1000

3 Pages

-

Vibrophore 100

3 Pages

-

Vibrophore 50

3 Pages

-

Vibrophore 25

3 Pages

-

LTM

5 Pages

-

roboTest A

2 Pages

-

roboTest B

2 Pages

-

roboTest I

2 Pages

-

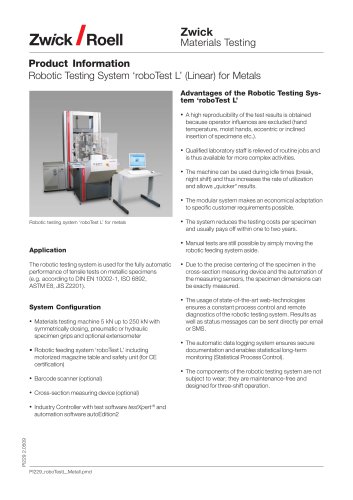

roboTest L FOR METALS

2 Pages

-

roboTest L FOR PLASTICS

2 Pages

-

roboTest L FOR ELASTOMERS

2 Pages

-

roboTest P

2 Pages

-

H-series

2 Pages

-

Z330E

3 Pages

-

Materials testing

2 Pages

-

HDT/Vicat Standard

4 Pages

-

Testing of Plastics and Rubber

56 Pages

-

Vicat Dry

2 Pages