Catalog excerpts

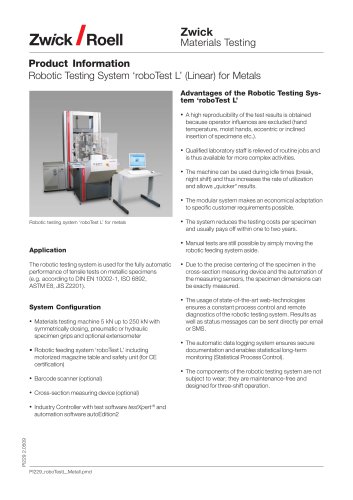

Zwick Materials Testing Zw/ck / RoellProduct Information Robotic Testing System ‘roboTest L’ (Linear) for plastics Advantages of the Robotic Testing System ‘roboTest L’ • A high reproducibility of the test results is obtained because operator influences are excluded (hand temperature, moist hands, eccentric or inclined insertion of specimens etc.). • Qualified laboratory staff is relieved of routine jobs and is thus available for more complex activities. • The machine can be used during idle times (break, night shift) and thus increases the rate of utilization and allows „quicker“ results. • The modular system makes an economical adaptation to specific customer requirements possible. • The system reduces the testing costs per specimen and usually pays off within one to two years. Application The robotic testing system is used for the fully automatic performance of tensile and flexure tests on plastics specimens (e.g. according to ISO 527-2 (1A, 1B, 1BA), ISO 178 or ASTM D790). System Configuration • Materials testing machine 5 kN up to 250 kN with symmetrically closing, pneumatic or hydraulic specimen grips and optional extensometer • Robotic feeding system ‘roboTest L’ • Barcode scanner (optional) • Cross-section measuring device (optional) • Industry Controller with test software testXpert ® and automation software autoEdition2 • Manual tests are still possible by simply moving the robotic feeding system aside. • Due to the precise centering of the specimen in the cross-section measuring device and the automation of the measuring sensors, the specimen dimensions can be exactly measured. • The usage of state-of-the-art web-technologies ensures a constant process control and remote diagnostics of the robotic testing system. Results as well as status messages can be sent directly per email or SMS. • The automatic data logging system ensures secure documentation and enables statistical long-term monitoring (Statistical Process Control). • The components of the robotic testing system are not subject to wear; they are maintenance-free and designed for three-shift operation.

Open the catalog to page 1

Zwick Materials Testing Zw/ck / Roell Product Information Robotic Testing System ‘roboTest Test Sequence • The user fills the removable specimen magazine at the specimen preparation or directly on the test system. The magazin will be placed on the magazine table. • The specimen data (ident number, width, thickness,...) are entered on the PC. In barcode operation this step can be omitted. • After the startup of the system, specimen feed, test and removal of the specimen fragments are carried out automatically. • After testing of all magazined specimens the magazine can be refilled or changed...

Open the catalog to page 2All ZWICK GMBH & CO. KG catalogs and technical brochures

-

HC Series

2 Pages

-

HB series

3 Pages

-

Vibrophore 1000

3 Pages

-

Vibrophore 250

3 Pages

-

Vibrophore 100

3 Pages

-

Vibrophore 50

3 Pages

-

Vibrophore 25

3 Pages

-

LTM

5 Pages

-

roboTest A

2 Pages

-

roboTest B

2 Pages

-

roboTest I

2 Pages

-

roboTest L FOR METALS

2 Pages

-

roboTest L FOR ELASTOMERS

2 Pages

-

roboTest P

2 Pages

-

H-series

2 Pages

-

Z330E

3 Pages

-

Materials testing

2 Pages

-

HDT/Vicat Standard

4 Pages

-

Testing of Plastics and Rubber

56 Pages

-

Vicat Dry

2 Pages