Catalog excerpts

Product Information Robotic Testing System ‘roboTest I’ (Impact) for pendulum impact testers Characteristics • The cooling of the specimen will be done via liquid nitrogen, the heating electrically. The heat transmission between the specimen and the tempering frame is via direct conductive contact. • Slides will do the specimen handling inside the temperature unit. The slides are manual (semiautomatic) or automatic (fully automatic) operated. • A PLC controls the temperature unit and the test process. Advantages of the robotic testing system ‘roboTest I’ Robotic testing system ‘roboTest I’ for pendulum impact tester RKP 450 or PSW 750 • A high reproducibility of the test results is obtained because operator influences are excluded (hand temperature, moist hands, eccentric or inclined insertion of specimens etc.). • The alignment of the specimen at the specimen The robotic testing system is used for semi or fully automatic tempering, feeding and testing of Charpy specimen according to EN10 045 or ASTM E23 at temperatures -180°C up to +300°C support and the start of the test are done automatically. • Enclosed system, no manual handling inside the liquid tank System configuration • A massive and isolated tempering frame guarantees a homogenous and exact specimen temperature. • Pendulum impact tester 450 J (semi automatic) or 750 J (semi or fully automatic) • The specimen temperature is measured by a thermo elements. • Semi automatic tempering and feeding unit ‘roboTest I’ (Impact) with a capacity of 10 specimens (optional 21 specimens) in the tempering unit • Fully automatic tempering and feeding unit ‘roboTest I’ (Impact) with a capacity of 10 specimens (optional 21 specimens) in the tempering unit and a integrated magazine for typically 90 specimens • Only one temperature unit is necessary for all temperatures • The system reduces the testing costs per specimen and usually pays off within one to two years. • The machine can be used during idle times (break, night shift) thus increasing the rate of utilization and al

Open the catalog to page 1

Zwick Materials Testing Zw/ck / RoellProduct Information Robotic Testing System ‘roboTest I’ (Impact) for pendulum impact testers Test sequence Technical DataTests_ • Test type Notched bar impact test Specimens_ • Specimen dimensions 10 x 5...10 x 55 mm • Material dimensionally stable • Length tolerance ± 0.5 mm •Height / width tolerance ± 0.2 mm Tempering_ Temperature range Cooling Heating Control precision Cycle time Feeding time Heating conductor Liquid nitrogen pressure Thermo elements Power consumption • All specimens have to be filled manually or automatically into the...

Open the catalog to page 2All ZWICK GMBH & CO. KG catalogs and technical brochures

-

HC Series

2 Pages

-

HB series

3 Pages

-

Vibrophore 1000

3 Pages

-

Vibrophore 250

3 Pages

-

Vibrophore 100

3 Pages

-

Vibrophore 50

3 Pages

-

Vibrophore 25

3 Pages

-

LTM

5 Pages

-

roboTest A

2 Pages

-

roboTest B

2 Pages

-

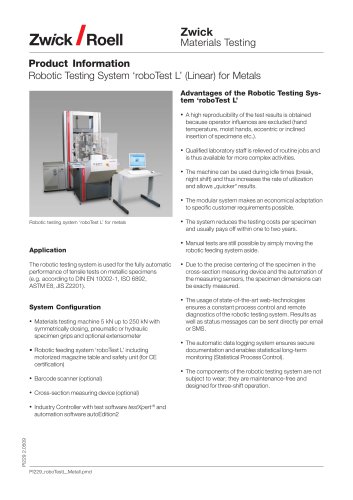

roboTest L FOR METALS

2 Pages

-

roboTest L FOR PLASTICS

2 Pages

-

roboTest L FOR ELASTOMERS

2 Pages

-

roboTest P

2 Pages

-

H-series

2 Pages

-

Z330E

3 Pages

-

Materials testing

2 Pages

-

HDT/Vicat Standard

4 Pages

-

Testing of Plastics and Rubber

56 Pages

-

Vicat Dry

2 Pages