Catalog excerpts

Zw/ck / Roell Testing Systems Dynamic and Fatigue Testing Systems Zw/ck / Roell Testing Systems

Open the catalog to page 1

Contents Page 1 The Zwick Roell Group 2 2.2 Vibrophores- high frequency 10 2.4 High-speed testing machines 16 3 Control electronics software 18 1 Zwick - ‘passion with competence’ For over 160 years the family-run business of the Zwick Roell Group has stood for outstanding technical achievement, innovation, quality and reliability in materials and component testing. A world leader, Zwick testing machines are used in research and development, production and quality assurance across a vast array of industries sectors. Zwick has a long tradition of excellence in the field of...

Open the catalog to page 2

At Zwick, we use a number of physical drive principles for our dynamic testing machines in order to cover the largest range of dynamic applications. These include: • Servo-Hydraulic • Electro-Magnetic • Electro-Mechanical Each drive system has its own advantages and areas of application. This allows Zwick to find an optimised solution for your specific testing needs in-line with your individual industry requirements. One of the key strengths of servo-hydraulic drive systems lies in their suitability to compliment a broad range of application and testing requirements. In terms of force,...

Open the catalog to page 3

2.1 Servo-hydraulic testing machines HA & HB Series up to 2500 kN The load frames and T-slot tables/beds of Zwick servohydraulic testing machines have been specially designed to cope with the demands and varied requirements of cyclic fatigue testing. The fundamental design principles of all servo-hydraulic machines are their high level of frame stiffness, hydrostatic-bearings and ergonomic working provisions. Depending on your individual testing and component requirements, the testing actuator is mounted either below or above the test area on our HA & HB frames. The HA frame represents the...

Open the catalog to page 4

Low-Cycle-Fatigue (LCF) testing A typical application for servo-hydraulic testing machines is low cycle fatigue (LCF) testing. This can be characterised by high amplitude, low-frequency, recurrent plastic deformation. Tests are usually compiled to plot an S-N curve. The LCF specimens typically withstand only a few thousand loading cycles and the number of cycles to failure significantly decreases at elevated temperatures. The specimen’s stiffness dramatically varies during testing. Therefore the demands placed on the testing machine and control hardware are particularly high in order...

Open the catalog to page 5

HC and HC Compact Series 10 kN & 25 kN The HC Series frames are smaller table-top or standalone hydraulic test machines, either with an integral power pack or mass compensating base for use with external pumps. With all HC models the actuator is positioned above the test area with a 2 column frame design and equipped with a T-slotted platform. The unique feature of HC Compact is its’ integral hydraulic powerpack for stand-alone operation with a minimal system footprint. The flow rate is 11 litres per minute and ample sound insulation makes these ideal for laboratory operation or where space...

Open the catalog to page 6

These models are variations of the proven HC and HB frame series due to their exceptional radial and axial frame stiffness. Zwick can equip these models with a combined torsional drive and linear actuator. The linear and rotary drive systems can be configured independently of each other or with freely adjustable phasing. The combined actuator is mounted on the upper crosshead, therefore components can be mounted on the integrated T-slotted platform. Advantages and features • Independent or phased control of rotary angle or linear stroke. • Optional hydraulic clamping and lift adjustment for...

Open the catalog to page 7

Special solutions As well as standardized systems, Zwick also designs and produces special dynamic testing systems, so that multi-axial systems, combined tension-torsion systems, testing systems with various media environments and large-scale testing systems all form part of our product range. If you cannot find a suitable solution to meet your requirements, please get in contact with us to see what is possible with a solution from our project division. Fig.2: Four-column HB250 for materials and component testing Fig.1: Configurable servo-hydraulic portal frame for component testing Fig.3:...

Open the catalog to page 8

Accessories for servo-hydraulic testing machines Zwick manufactures a large variety of accessories and test tooling for our dynamic testing product range. The range is constantly being expanded through a program of continuous development. The inclusion of new products allows us to satisfy our customers’ most demanding test requirements whilst continuously improving our scope of supply in the dynamic marketplace. Specimen grips & accessories Compression platens Alignment fixture Hydraulic parallel grips Hydraulic wedge grips Media bath Flexure test kits High-temp. furnaces Temperature...

Open the catalog to page 9

2.2 Vibrophores Modern laboratories and institutes, whether in research, training or industry, increasingly find themselves confronted with frequently changing testing requirements. The latest generation of Vibrophores (high-frequency pulsators) from Zwick can be used as both dynamic and fully-fledged static materials testing machines, a first for this type of machine and with test loads of up to 1000 kN. This makes them an attractive proposition also for laboratories which mainly perform static tests, as well as for those which mainly carry out dynamic tests, with only the occasional...

Open the catalog to page 10

Fig.1: Examples of typical Vibrophore applications Fig.2: Threaded round specimen with fast clamping device Typical Vibrophore applications Connecting rods High temperature specimens SENB specimens Flat specimens

Open the catalog to page 11

Static tests using the Zwick Vibrophore Mechanical clamping of the oscillating crosshead and the deployment of testXpert II software transform the Vibrophore into a fully-fledged static materials testing machine. Generous connecting surfaces and ruggedly dimensioned components ensure high machine stiffness. This combines with precision crosshead guidance to ensure that unacceptable mechanical influences on the specimen are minimized. By using suitable additional devices, both static and dynamic testing can be performed under various environmental conditions (temperature, aggressive media),...

Open the catalog to page 12All ZWICK GMBH & CO. KG catalogs and technical brochures

-

HC Series

2 Pages

-

HB series

3 Pages

-

Vibrophore 1000

3 Pages

-

Vibrophore 250

3 Pages

-

Vibrophore 100

3 Pages

-

Vibrophore 50

3 Pages

-

Vibrophore 25

3 Pages

-

LTM

5 Pages

-

roboTest A

2 Pages

-

roboTest B

2 Pages

-

roboTest I

2 Pages

-

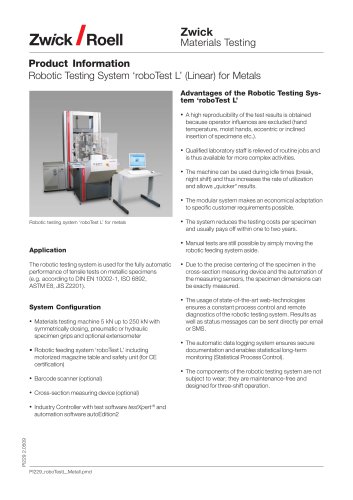

roboTest L FOR METALS

2 Pages

-

roboTest L FOR PLASTICS

2 Pages

-

roboTest L FOR ELASTOMERS

2 Pages

-

roboTest P

2 Pages

-

H-series

2 Pages

-

Z330E

3 Pages

-

Materials testing

2 Pages

-

HDT/Vicat Standard

4 Pages

-

Testing of Plastics and Rubber

56 Pages

-

Vicat Dry

2 Pages