Catalog excerpts

VAISALA Visibility Sensor FS11 is intended for the most demanding weather applications, such as runway visual range (RVR), aeronautical and synoptical visibility. It provides the optimal combination of the best accuracy, the highest reliability, broad measurement range, and low maintenance need. Features • Unique window contamination correction • Accurate and traceable forward scattering measurement • Technical design and high-power heating according to FAA guidelines • Frangible composite fiber mast • Can be upgraded for sensing present weather • The most widely proven forward scatter RVR sensor • Visibility sensor selected and used by FAA • Meets FAA and ICAO specifications • Accurate and traceable measurement • Can be used for both aeronautical and synoptical applications • Minimal maintenance needs • Meets ICAO frangibility standards The main applications of FS11 are runway visual range (RVR) and synoptical and aeronautical visibility measurements. FS11 is also well suited for other demanding applications, such as visibility measurement at ports and harbors. Scientifically Valid Chain of Calibration FS11 is calibrated through a scientifically valid chain of reference. The scattering response of the calibration device can be clearly traced to a reference FS11 visibility sensor, which is in continuous operation at Vaisala outdoor test field along with reference transmissometers and other instrumentation. The visibility measurement of FS11 is also traceable to FAA reference sensors. Low Maintenance Need FS11 incorporates a technique that measures and compensates for window contamination. It ensures unparalleled measurement accuracy between window cleanings. It also enables much longer window cleaning intervals than compared to conventional visibility sensors. The unique system works by monitoring the total reflectance of the window surface. It automatically compensates for visibility measurement errors caused by window contamination. The sophisticated self-diagnostics and modular design allow for very short service times. The measurement fork and optional background luminance sensor LM21 are independent instruments that can be replaced quickly as pre-calibrated spare parts. Reliable Operation in the Harshest Weather Four main design features are combined in FS11 to ensure reliable operation in the harshest weather. The first is the window contamination compensation technique. The second is the “head-down” design of the optical heads, which protects them against virtually all windblown particles (even those flying horizontally). High-power heaters are the third feature. Each heater has its own temperature monitoring and control mechanism to prevent snow accumulation during the heaviest snowstorm. As a final measure, there is an optical path clearance monitoring circuitry to verify that measurement is not affected by obstructions

Open the catalog to page 1

Measurement Performance Spare Parts and Accessories Scatter measurement accuracy Obstruction light Optical Specifications Operating principle Forward scatter measurement Light source Near-infrared LED Operating Environment EMC Compliance Radiated emissions EN55022 Harmonics to the AC (mains) grid IEC 61000-3-2 AC (mains) power supply 100/115/230 VAC ±10 %, 50 ... 60 Hz defrosting heaters) Battery backup option Battery 2 Ah, typical backup time 30 min at 25 °C (77 °F) and 5 min at -40 °C (-40 °F) Outputs Serial data line RS-232 or opto- isolated RS-485 (2-wire) or optional data modem...

Open the catalog to page 2All VAISALA OYJ catalogs and technical brochures

-

PWD series

5 Pages

-

Insight

2 Pages

-

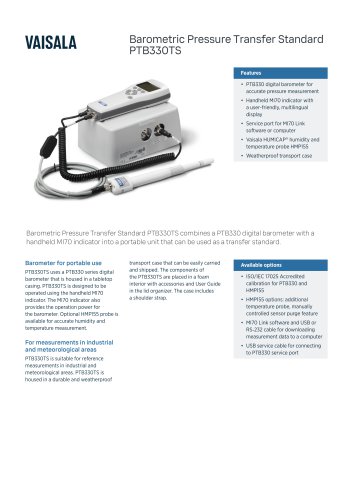

PTB330TS

3 Pages

-

HMP155

2 Pages

-

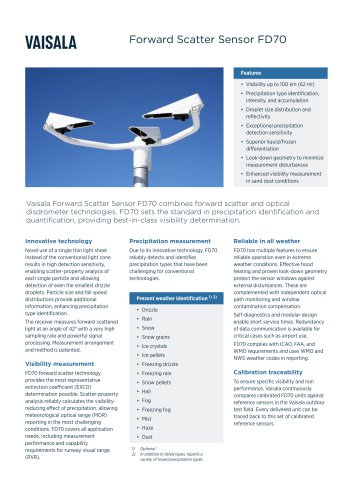

FD70

2 Pages

Archived catalogs

-

Thunderstorm Manager

2 Pages

-

The Vaisala AUTOSONDE® AS41

5 Pages

-

Vaisala Lightning Exporter

2 Pages

-

Vaisala Lightning Integrator

2 Pages

-

Lightning Threat Zone API

2 Pages

-

Vaisala Thunderstorm Manager

2 Pages

-

Vaisala Thermal Mapping

2 Pages

-

Vaisala BeaconTM Station

2 Pages

-

A clearer approach to RVR

8 Pages

-

RFL100

4 Pages

-

HMP8

2 Pages

-

PTU300

5 Pages

-

Present Weather Sensor FS11P

2 Pages

-

RWS200

24 Pages

-

Vaisala AviMet® DSS

4 Pages

-

Vaisala: a sound decision

8 Pages