Catalog excerpts

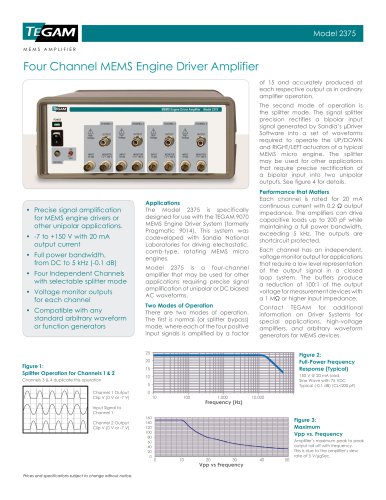

Model 2375 MEMS AMPLIFIER Four Channel MEMS Engine Driver Amplifier of 15 and accurately produced at each respective output as in ordinary amplifier operation. The second mode of operation is the splitter mode. The signal splitter precision rectifies a bipolar input signal generated by Sandia’s µDriver Software into a set of waveforms required to operate the UP/DOWN and RIGHT/LEFT actuators of a typical MEMS micro engine. The splitter may be used for other applications that require precise rectification of a bipolar input into two unipolar outputs. See figure 4 for details. • recise signal amplification P for MEMS engine drivers or other unipolar applications. • 7 to +150 V with 20 mA output current • ull power bandwidth, F from DC to 5 kHz (-0.1 dB) • our Independent Channels F with selectable splitter mode • oltage monitor outputs V for each channel • ompatible with any C standard arbitrary waveform or function generators Applications The Model 2375 is specifically designed for use with the TEGAM 9070 MEMS Engine Driver System (formerly Pragmatic 9014). This system was codeveloped with Sandia National Laboratories for driving electrostatic, comb-type, rotating MEMS micro engines. Model 2375 is a four-channel amplifier that may be used for other applications requiring precise signal amplification of unipolar or DC biased AC waveforms. Two Modes of Operation There are two modes of operation. The first is normal (or splitter bypass) mode, where each of the four positive input signals is amplified by a factor Performance that Matters Each channel is rated for 20 mA continuous current with 0.2 Ω output impedance. The amplifiers can drive capacitive loads up to 200 pF while maintaining a full power bandwidth, exceeding 5 kHz. The outputs are shortcircuit protected. Each channel has an independent, voltage monitor output for applications that require a low level representation of the output signal in a closed loop system. The buffers produce a reduction of 100:1 of the output voltage for measurement devices with a 1 MΩ or higher input impedance. Contact TEGAM for additional information on Driver Systems for special applications, high-voltage amplifiers, and arbitrary waveform generators for MEMS devices. Figure 1: Splitter Operation for Channels 1 & 2 Channels 3 & 4 duplicate this operation Channel 1 Output Clip V (0 V or -7 V) Input Signal to Channel 1 Channel 2 Output Clip V (0 V or -7 V) Figure 2: Full-Power Frequency Response (Typical) 150 V @ 20 mA load. Sine Wave with 75 VDC Typical (-0.1 dB) (CL<200 pF) Figure 3: Maximum Vpp vs. Frequency Prices and specifications subject to change without notice. Amplifier’s maximum peak to peak output roll off with frequency. This is due to the amplifier’s slew

Open the catalog to page 1

MEMS AMPLIFIER Model 2375 Specifications Electrical Number of Channels Input Impedance Output Voltage Range Maximum Output Current Output Impedance Voltage Gain Sine Wave Distortion (THD) Full Power Bandwidth Slew Rate Square Wave Response Aberrations Voltage Monitor Outputs Environmental Operating Temperature Storage Temperature Humidity Range General Input Supply Voltage Power Rating Dimensions: (H x W x L) Weight (approximate) Warranty Included Accessories Optional Accessories 4 10 kQ 0 to +150 VDC (Splitter Mode) -7 to +150 VDC (Splitter Bypass Mode) 20 mA per channel < 0.2 Q +15...

Open the catalog to page 2All Tegam catalogs and technical brochures

-

Decade Ratio Transformer

2 Pages

-

R1L-E2A

2 Pages

-

R1L-D1

2 Pages