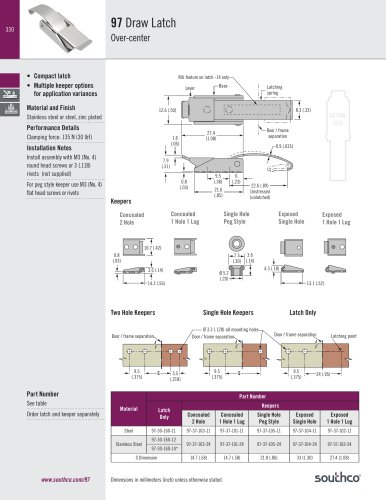

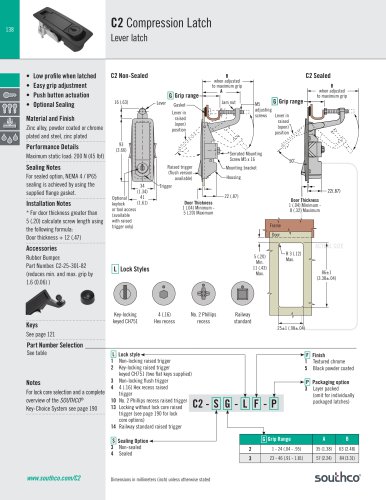

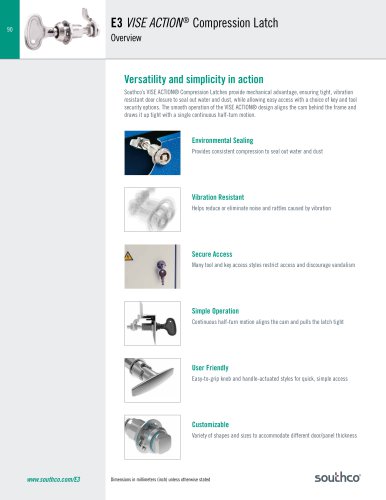

Catalog excerpts

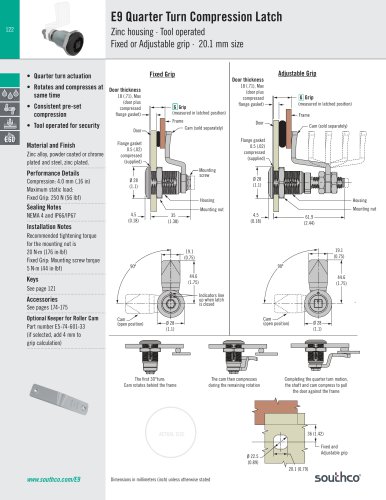

E9 Quarter Turn Compression Latch Zinc housing · Tool operated Fixed or Adjustable grip · 20.1 mm size Fixed Grip • Quarter turn actuation Door thickness • Rotates and compresses at Door thickness same time 18 (.71), Max • Consistent pre-set compression • Tool operated for security Material and Finish Zinc alloy, powder coated or chrome plated and steel, zinc plated. (door plus compressed flange gasket) G Grip (measured in latched position) Frame Cam (sold separately) Mounting screw Installation Notes Recommended tightening torque for the mounting nut is 20 N∙m (176 in∙lbf) Fixed Grip: Mounting screw torque 5 N∙m (44 in∙lbf) Frame Door 44.6 (1.75) Indicators line up when latch is closed Accessories See pages 174-175 Optional Keeper for Roller Cam Part number E5-74-601-33 (if selected, add 4 mm to grip calculation) (measured in latched position) Sealing Notes NEMA 4 and IP66/IP67 18 (.71), Max (door plus compressed flange gasket) Flange gasket 0.5 (.02) compressed (supplied) Flange gasket 0.5 (.02) compressed (supplied) Performance Details Compression: 4.0 mm (.16 in) Maximum static load: Fixed Grip: 250 N (56 lbf) Adjustable Grip The first 30°turn: Cam rotates behind the frame The cam then compresses during the remaining rotation ACTUAL SIZE Completing the quarter turn motion, the shaft and cam compress to pull the door against the frame 36 (1.42) Fixed and Adjustable grip Dimensions in millimeters (inch)

Open the catalog to page 1

Latch Installation Method Gasket ___________________________________________________________________________ Part Number Selection Order latch and cam separately 1 Black powder coated 2 Silver powder coated 3 Chrome Plated Slotted recess Bellcore electronics Railway standard Fixed Grip Adjustable Grip Latch unassembled Turn clockwise to latch Latch unassembled Turn counter-clockwise to latch Latch unassembled Turn clockwise to latch Latch unassembled Turn counter-clockwise to latch Stable frame engagement Improved surface contact Minimal frame surface prep Protective cam covering Provides...

Open the catalog to page 2

E9 Quarter Turn Compression Latch Accessories Cam: Steel Protected cam: Steel, nylon Roller cam: Steel, nylon Stable frame engagement Improved surface contact Minimal frame surface prep Protective cam covering Provides smoother operation Reduces scratching frame Reduces operating effort Minimize scratching frame finish Detented feel (with optional keeper) Fixed Grip Cams – for use with E9 zinc latches Cam Part Number Table (order separately from latch) Cam Protected Cam Grip Grip Part Number Part Number If grip falls between two choices, use smaller option www.southco.com/E9 Roller Cam Part...

Open the catalog to page 3

Adjustable Grip Latch Fixed Grip Latch Adjustable Grip Cams – for use with E9 zinc latches Cam Part Number Table (order separately from latch) Minimum Grip Maximum Grip Part Number Protected Cam Part Number Table (order separately from latch) Minimum Grip Maximum Grip Part Number Deep offset cam, forward Deep offset cam, reverse Roller Cam Part Number Table (order separately from latch) Minimum Grip Maximum Grip Part Number Optional Keeper for Roller Cam Part number E5-74-601-33 (if selected, add 4 mm to grip calculation) Dimensions in millimeters (inch) unless otherwise stated

Open the catalog to page 4