Catalog excerpts

Solid Carbide Tools

Open the catalog to page 1

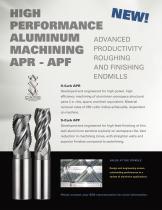

ADVANCED PRODUCTIVITY ROUGHING AND FINISHING ENDMILLS S-Carb APR Developed and engineered for high power, high efficiency machining of aluminium aerospace structural parts (i.e. ribs, spars) and their equivalent. Material removal rates of 550 cubic inches achievable, dependent on machine. S-Carb APF Developed and engineered for high-feed finishing of thin wall aluminium sections typically on aerospace ribs. Vast reduction in machining times, with straighter walls and superior finishes compared to waterlining. Design and engineering ensure outstanding performance in a variety of aluminum...

Open the catalog to page 2

APR S-CARB APR • flute design for high feed 3 power roughing • High feed direct plunge ability • Through coolant design • olished flute design to P maximize chip evacuation • 4 flute unique variable geometry reduces vibration and allows finishing of thin walls in one pass • Through coolant design • Polished flutes for superior finishes • Significant reduction in cycle times Typical Method: High-speed waterline finishing, multiple passes at numerous levels to produce acceptable thin walls APF Method: High speed finishing at full depth without wall distortion 'One Hit' Please contact your SGS...

Open the catalog to page 3

Series 43 S-Carb APR – 3 Flute TOLERANCES (inch) DIAMETER D1 CORNER RADIUS TOLERANCES (inch) CORNER RADIUS TOLERANCES (mm) Available on request: • JetStream Technology • Side exits fo

Open the catalog to page 4

Series 43 S-Carb APF – 4 Flute TOLERANCES (inch) DIAMETER D1 1/2 - 3/4 CORNER RADIUS TOLERANCES (inch) CORNER RADIUS TOLERANCES (mm) Available on request: • JetStream T

Open the catalog to page 5

Fractional & Metric | Speed & Feed Recommendations Series S-Carb APR Fractional Note: • surface speed is dependent on machine spindle & fixturing^ • balancing is recommended at ultra high surface speeds • tool life may be reduced when machining Lithium Alloys • rpm = (1000 x m/min) / (3.14 x D1) • mm/min = (mm / flute) x rpm maximum recommended depths shown reduce speed and feed for materials harder than listed ramp angle = 15“ (feed rate = 30%) maximum ramp depth = 1 x D1 plunge depth = 1 x D1 (feed rate = 30%) refer to the SGS Tool Wizard for complete technical information (www.sgstool.com)

Open the catalog to page 6

Series S-Carb APF Fractional Fractional & Metric | Speed & Feed Recommendations Vc (sfm) ALUMINUM ALLOYS 2024, 5052, 5086, 6061, 6063, 7075 Tool Wizard CALCULATE APPLICATION PARAMETERS www.sgstool.com surface speed is dependent on machine spindle & fixturing* balancing is recommended at ultra high surface speeds tool life may be reduced when machining Lithium Alloys rpm = (1000 x m/min) / (3.14 x D1) mm/min = (mm / flute) x rpm maximum recommended depths shown reduce speed and feed for materials harder than listed finish cuts typically require reduced feed and cutting depths of 0.02 x D1...

Open the catalog to page 7

Solid Carbide Tools VALUE AT THE SPINDLE Solutions Around The Globe SGS Tool Company is a privately-held, ISO-certified leader of round solid carbide cutting tool technology for the aerospace, metalworking, and automotive industries with manufacturing sites in the United States and United Kingdom. Our global network of Sales Representatives, Industrial Distributors, and Agents blanket the world selling into more than 60 countries. Leaders in Solid Carbide Tool Technology Brand names such as Z-Carb, S-Carb, V-Carb, Hi-PerCarb, Multi-Carb have become synonymous with high performance tooling...

Open the catalog to page 8All SGS FRANCE catalogs and technical brochures

-

M155 series

2 Pages

-

HI-PERCARB® 142P

104 Pages

-

HI-PERCARB® 143M-S

104 Pages

-

Z-Carb HPR

16 Pages

-

PCR

8 Pages

-

T-Carb

12 Pages

-

Series 33

8 Pages

-

Performance for Aluminum

44 Pages

-

Composites

20 Pages

-

High Performance Drills

52 Pages

-

SGS-Speeds-Feeds-Z1

2 Pages

-

SGS-Speeds-Feeds-7

1 Pages

-

SGS-Speeds-Feeds-55

2 Pages

-

multi-carb

12 Pages