Catalog excerpts

SECO NEWS 2019.1 JETI CONVERSION GROOVING & PARTING-OFF 1 Copyright © 2018 Seco Tools AB

Open the catalog to page 1

SAFETY FIRST Emergency Exit Emergency Number Assembly Point Protective Equipment Copyright © 2018 Seco Tools AB

Open the catalog to page 2

3 Copyright © 2018 Seco Tools AB Complicated and timeconsuming tool exchanges Frequent machine stoppages Poor machining performance Short tool life Common Customer Challenges Low-quality parts Unreliable processes

Open the catalog to page 3

■ Deep cuts —► difficult for coolant to reach cutting zone ■ Challenging materials —► high temperature in the cutting zone ■ Long, difficult-to-remove chips prevent efficient cooling, reduce tool life, affect part quality and increase machine down-time ■ External coolant-delivery equipment interferes during machining ■ Time-consuming tool change 4 Copyright © 2018 Seco Tools AB SECO I

Open the catalog to page 4

Improves performance and tool life Stabilizes processes Eliminates long chips Reduces down-time Simplifies tool change process Eliminate limitations caused by external piping 5 Copyright © 2018 Seco Tools AB SECO I

Open the catalog to page 5

6 Copyright © 2018 Seco Tools AB SECO I

Open the catalog to page 6

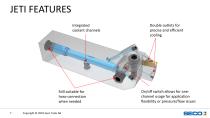

JETI FEATURES Integrated coolant channels Still suitable for hose connection when needed 7 Copyright © 2018 Seco Tools AB Double outlets for precise and efficient cooling On/off switch allows for onechannel usage for application flexibility or pressure/flow issues

Open the catalog to page 7

Copyright © 2018 Seco Tools AB

Open the catalog to page 8

JETI: A FLEXIBLE PROBLEM SOLVER User-friendly hoseless connection Complicated and timeconsuming tool exchanges Fewer extra spare parts Short tool life Common Customer Challenges Frequent machine stoppages Excellent chip control Copyright © 2018 Seco Tools AB Precise, efficient high-pressure cutting edge cooling Poor machining performance Low-quality parts Unreliable processes Optimized coolant delivery for wider range of applications with Duo/Single JETI

Open the catalog to page 9

■ MDT Jetstream Tooling® holders with shank sizes 20 x 20 mm or 25 x 25 mm and insert pocket seat sizes from 2 to 8 mm, both radial and axial - 182 items ■ X4 holders with shank sizes 20 x 20 mm or 25 x 25 mm - 4 items ■ 150.10 holders for 15-size blades and with shank sizes 20 x 20 mm or 25 x 25 mm - 4 items 10 Copyright © 2018 Seco Tools AB SECO I

Open the catalog to page 10

Copyright © 2018 Seco Tools AB

Open the catalog to page 11

PRODUCT RANGE ADAPTERS For available shank adapters – Seco-Capto, HSK-T, VDI – see My Pages

Open the catalog to page 12

JETI SUMMARY Precise, fully integrated coolant delivery r?\ Improved performance provides new opportunities for optimization Reduced production costs

Open the catalog to page 13All SECO TOOLS catalogs and technical brochures

-

Solid End Mills.pdf

641 Pages

-

Indexable Milling Catalog.pdf

856 Pages

-

Taper-Face Toolholders.pdf

23 Pages

-

GL25-HEADS RANGE EXPANSION

13 Pages

-

SECO NEWS SUMMARY 2019.1

9 Pages

-

DOUBLE OCTOMILL™

2 Pages

-

PRODUCT SUMMARY

2 Pages

-

SECO NEWS SUMMARY 2018.1

14 Pages

-

POZVÁNKA ZD KOVOSVIT

1 Pages

-

Machinability_poster

1 Pages

-

SQUARE T4

2 Pages

-

SECO Product summary

2 Pages

-

SECO NEWS

310 Pages

-

DURATOMICTM

16 Pages

-

QUATTROMILL-AL™

2 Pages

Archived catalogs

-

DISC MILLING

36 Pages