Catalog excerpts

SANMAC BAR AND HOLLOW BAR STAINLESS STEELS FOR MACHINING

Open the catalog to page 1

PRODUCT OFFER-STAINLESS BAR STEEL 7 PRODUCT OFFER - STAINLESS HOLLOW BAR 16 Technical data for bar and hollow bar (metric) 30 Technical data for bar and hollow bar (imperial) 32 The art of machining stainless steel 36 SANMAC IMPROVES YOUR PRODUCTION ECONOMY Sanmac ® is the result of extensive efforts to improve the machinability of stainless steel grades and the design of tooling concepts suitable for stainless steel machining. The result of this co-operation between Sandvik Materials Technology and Sandvik Coromant is improved production economy for you as our customer. Higher productivity...

Open the catalog to page 2

SANMAC - ALWAYS AT THE CUTTING EDGE The benefits you will experience are: Improved cutting speeds and feed rates • Higher productivity per machine • Reduced fixed cost per machined component More machining time per insert edge due to less tool wear • Better machine utilisation through reduced stoppage time Integrated production (own melting) • Continuity from melt to melt • Less machine setting time and fewer rejections Excellent availability (from local stocks) • Reduced customer inventories • Reliable delivery service • Well established distributor network Wide selection of dimensions •...

Open the catalog to page 3

PRODUCT OFFER STAINLESS BAR STEEL

Open the catalog to page 4

GRADES AND STANDARDS Stainless bar steel Sandvik®ENUNSAISI Stock standard Sanmac® 316 / 316L 1.4401 / 1.4404 S31600 / S31603 Type 316 / 316L Production order All stock standard grades can be produced on production order. Product standards (Applicable for both Production and Stock grades and sizes) EN10088-3 , EN 10222-51) AD2000-W23) ASTM A479, ASME SA479 NACE MR0103 ASTM A276, ASME SA 276 ASTM A-182 Size range, mm Inch Sanmac 304 / 304L Sanmac 316 / 316L Sanmac 4435 Sanmac 4571 Sanmac 3294) Sanmac 2205 / Sandvik SAF 2205™ Sandvik SAF 32760 Sandvik SAF 2507™_ Grade Sanmac 316 / 316L Sanmac...

Open the catalog to page 5

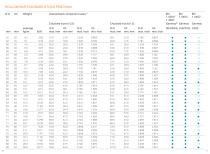

SOLID BAR STANDARD STOCK PROGRAM Sandvik stainless round bars can be delivered in random or fixed lengths. Depending on size, the following surface finish is offered. • Peel turned and burnished (PTB) • = stock standard item, central warehouse • Peel turned (PT) O = produced to order (contact us about min.quantity)

Open the catalog to page 6

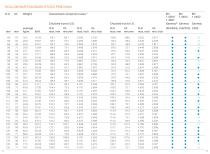

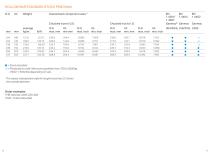

SOLID BAR STANDARD STOCK PROGRAM Sandvik stainless round bars can be delivered in random or fixed lengths. Depending on size, the following surface finish is offered. • = stock standard item, central warehouse O = produced to order (contact us about min.quantity) • Peel turned and burnished (PTB) • Peel turned (PT) • Rough machined (RM) Diameter Tolerance Random length, Surface mm inch mm inch m/feet Weight Sanmac® Sanmac

Open the catalog to page 7

SOLID BAR STANDARD STOCK PROGRAM Sandvik stainless round bars can be delivered in random or fixed lengths. Depending on size, the following surface finish is offered. • = stock standard item, central warehouse O = produced to order (contact us about min.quantity) • Peel turned and burnished (PTB) • Peel turned (PT) • Rough machined (RM) Random length, m/feet Sandvik Sandvik

Open the catalog to page 8

PRODUCT OFFER STAINLESS HOLLOW BAR

Open the catalog to page 9

GRADES AND STANDARDS Stainless hollow bar - grades Sandvik® UNS ASTM EN steel no. Produced to order Sanmac 4435 S31600/31603 316/316L 1.4436/1.4435 All above grades fulfill the requirements of PED/2014/68/EU (EN 10216-5) leak tightness test deferred to machined component Chemical composition Sandvik Nominal chemical composition, % Other grades to special order. Tolerances O.D. +2/-0% but minimum +1/-0 mm (+0.04/-0”). Straightness: Straightness deviation max. 1.5 mm per 1000 mm (0.059 inch per 3 ft). Other tolerances can be offered to special order. Lengths Sandvik stainless hollow bar is...

Open the catalog to page 10

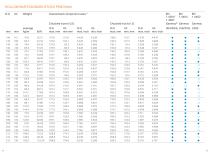

HOLLOW BAR STANDARD STOCK PROGRAM O.D. I.D. Weight Guaranteed component sizes 11 Chucked true to O.D. average O.D. I.D. O.D. I.D. mm mm kg/m lb/ft max. mm min mm max. inch min. inch 1.4307 Chucked true to I.D. Sanmac® Sanmac Sanmac

Open the catalog to page 11

Guaranteed component sizes 11 Chucked true to O.D. O.D. I.D. O.D. I.D. max. mm min.mm max. inch min. inch 1.4307 Chucked true to I.D. Sanmac® Sanmac Sanmac max. mm min.mm max. inch min. inch

Open the catalog to page 12

HOLLOW BAR STANDARD STOCK PROGRAM O.D. I.D. Weight Guaranteed component sizes 11 Chucked true to O.D. average O.D. I.D. O.D. I.D. mm mm kg/m lb/ft max. mm min mm max. inch min. inch 1.4307 Chucked true to I.D. Sanmac® Sanmac Sanmac

Open the catalog to page 13

O.D. I.D. Weight Guaranteed component sizes 11 EN EN EN 1.4307 Chucked true to O.D. Chucked true to I.D. Sanmac® Sanmac Sanmac mm mm kg/m lb/ft max. mm min mm max. inch min. inch max. mm min. mm max. inch min. inch • = Stock standard O = Produced to order. Minimum quantities from 750 to 5000kg (1500-11000 lbs) depending on size. "The values indicated are valid for lengths less than 2.5 times the outside diameter. Order examples THB-Sanmac 2205-250-200 (THB = Tube Hollow Bar)

Open the catalog to page 14

Steel type Sulph. Nitric Formic Acetic Pitting/ SCC acid acid acid acid crevice Sandvik® corr. Sandvik SAF 32760 ++ + +++ ++ +++++ +++++ Sandvik SAF 2507™ ++ + +++ ++ +++++ +++++ Sandvik Sanicro 28 +++++ ++ + ++ ++++ +++ + 0 = Reference value + = More resistant than reference value - = Less resistant than reference value WELDABILITY Suitable welding methods for Sanmac grades are manual metal arc welding with covered electrodes MMA and gas shielded arc welding, with the TIG and MIG methods as first choice. During TIG welding, especially autogenous welding, a correct setting of the welding...

Open the catalog to page 18

THE ART OF MACHINING STAINLESS STEEL Austenitic and duplex stainless steels have certain properties that makes them difficult to machine compared to carbon steels or ferritic and martensitic stainless steels. The greatest difference is the high ductility of austenitic and duplex stainless steels, as well as their tendency to work harden and form built-up edges on the cutting tool. Moreover, in duplex materials, chip forming becomes more difficult due to the high strength of these materials. In Sanmac® materials, machinability has been improved without jeopardising properties such as...

Open the catalog to page 19All SANDVIK MATERIALS TECHNOLOGY catalogs and technical brochures

-

SANDVIK ROCK DRILL STEEL

4 Pages

-

AquaSan Ni50

2 Pages

-

APM 9980

4 Pages

-

APM 2723

5 Pages

-

APM 2377, UNS S31803

4 Pages

-

APM 2354, UNS S31603

3 Pages

-

APM 2327, UNS S32505

4 Pages

-

Sandvik precision strip steel

16 Pages

-

SANMAC 4571

10 Pages

-

Sandvik billets and blooms

10 Pages

-

ROUND BAR SIZES AND GRADES

4 Pages

-

Sanmac®329

2 Pages