Catalog excerpts

STREAM FINISHING UNITS SF SERIES PERFECT SURFACES WORLDWIDE

Open the catalog to page 1

2 | THE PROCESS STREAM FINISHING OTEC: WE MAKE THE DIFFERENCE The OTEC stream finishing process offers much shorter processing times compared to conventional procedures. It also allows users to automate processes easily without jeopardising reliability. The shorter cycle times mean that the systems can be integrated smoothly into industrial production lines. Camshaft Lower Rpk values, leading to lower friction and greater energy effi ciency. Lower metal abrasion in the oil, resulting in longer replacement intervals In this new process, one or more workpieces are clamped in a holder and...

Open the catalog to page 2

SF 2 RLS Milling tool Rounding the cutting edges increases tool life Inner forming die Tools in outstanding quality Polished forming surfaces lead to longer service lives and lower wear Thread-cutting taps Polishing reduces cutting forces and wear Turbine blades Defi ned rounding of inlet and outlet edges with uniform smoothing and no adverse effect on the blade form

Open the catalog to page 3

WE GET YOU TO THE FINISH WITH µ PRECISION OTEC-optimized surfaces ensure that workpieces fulfil the high quality requirements of our customers. The focus here is on the finish or properties of the surface. In series production, reliable repeatable results and cost effectiveness deliver a real competitive edge. Precision finishing Rounding cutting edges This fast mass finishing process ensures ex tremely short process times, even with complex shapes. Parts can be deburred, rounded, smoothed or polished in a single work step. This process also effortlessly achieves roughness depths of far below...

Open the catalog to page 5

OTEC stream finishing machines offer versa- AUTOMATIC QUALITY tile, flexible and efficient surface finishing for small or large series production. If required, they can be fitted with the right automation systems for every application. By choosing an OTEC SF, not only are you choos ing uncompromising German quality, but a secu re future too. With a comprehensive range of standard equip ment, optional extras and countless automation choices, our machines help you scale your pro duction. You can increase operating comfort and pro cess reliability further with optional modules. Immersion depth...

Open the catalog to page 6

STOP & GO HELPS ACHIEVE GOALS QUICKLY The smart optional PULSFINISH process ensures an extremely intensive and precisely controllable surface result in a fraction of the normal time. 1/min. Alternating direction of rotation The newly developed PULSFINISH process is 2500 based on repeated, precisely defined movement intervals between the media and the workpiece, with up to 2,000 rpm. The varying speeds caused 2000 by the inertia of the rotating media in the container, together with the fast workpiece speed changes, lead to relative accelerations of 1500 up to 40 g. The optional pulse drive...

Open the catalog to page 7

THE QUALITY SERIES FOR SERIOUS QUALITY Perfectly suited for workpiece processing in small to medium sized production lines. The solution of choice for processing small workpiece batches and frequently changing series.

Open the catalog to page 8

SF RLS AUTOMATION Perfect for processing high quantities in flexible production. We reinvent ourselves, just for you Do you have exceptional requirements for which there is not yet a solution on the market? Speak to us. As the technology leader in innovative stream finishing machines, special solutions made to our customers' specifications are our particular strength. We work closely with you to develop a highly customized solution, including the most suitable process. Our team will be pleased to advise you without any cost or obligation on your part and in absolute confidence. Call us: +49...

Open the catalog to page 9

OTEC SF RLS PERFECT FOR MASS PRODUCTION The SF RLS (robot loading system) is our answer to questions related to automation and integration in modern production lines, such as in the automotive or tooling industries. The OTEC SF RLS can also be fitted with the newly developed pulse drive. This allows users to meet the demanding speed, quality and reli ability requirements in mass production. It also offers three workpiece holders, allowing three workpieces to be processed simultaneously and changed during the process. These three workpiece holders are cycled and can be con trolled...

Open the catalog to page 10

Touch panel for controlling the robot arm on the SF RLS A chain loader on the SF 1 ILS fitted with tool OTEC SF ILS NON-STOP QUALITY The SF 1 ILS (Integrated Loading System) is the compact OTEC base model for tool processing with automatic loading. The SF1 ILS with chain loader is the new stand ard in automated precision finishing. The ma chine requires no expertise in robotics and is designed for maximum user friendliness. Both the SF and the chain loader are operated via a control panel. It features a chain loader with 64 or 160 positions and can process different work pieces in a single...

Open the catalog to page 11

Automatic loading available on request The X after SF stands for the possible number of holders Designed for automatic operation. Manual loading allows for larger dimensions

Open the catalog to page 12

Standard equipment o Process drum for dry finishing, in steel, painted exterior with stripper brush o Process drum for wet finishing, in stainless steel, painted o Manual clamping of workpieces o Workpiece angle adjustable up to 30° o Electromechanical immersion by means of lift system o Touch screen operation via Siemens S7 control system o Rotary speed infinitely adjustable via frequency converter o Automated process control o Direction of rotation can be preset with automatic reversal of direction Options o Additional process drum for wet or dry finishing o Trolley for changing process...

Open the catalog to page 13

14 | PROCESS DEVELOPMENT AND MEDIA MACHINE AND PROCESS – THE DUAL SOLUTION Every workpiece is different. For a reproducible and efficient process which always results in a perfect surface, all relevant parameters are determined and documented in the lab. The measurement log shows the edge rounding in the μm range Our OTEC research lab offers you a professional service and can develop a process finetuned to your workpiece and your application. After processing a sample, we first create a log documenting all process parameters. On the basis of this information, the details of stock removal,...

Open the catalog to page 14All OTEC Präzisionsfinish GmbH catalogs and technical brochures

-

FLOW SEPARATION-FS SERIES

2 Pages

-

EPAG Flex modular

2 Pages

-

ECO, EF SERIES

7 Pages

-

CF & EPAG SERIES

8 Pages

-

SERIE CF ELEMENT

2 Pages

-

MASS FINISHING MACHINES

14 Pages

-

Media

7 Pages

-

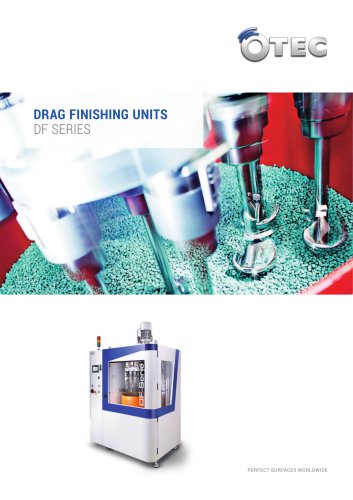

DRAG FINISHING UNITS DF SERIES

14 Pages