Catalog excerpts

Precision finish demands PERFECT SURFACES WORLDWIDE

Open the catalog to page 1

MEDIA FOR PERFECT SURFACES The quality of any given surface depends on choosing the right combination of machine and process media. The media must be carefully selected to match each individual type of workpiece. The composi -tion and shape of the media and the selection of suitable process parameters are all key factors. Making the right decisions demands experience and expertise. In the case of tools, getting these factors right can determine the quality of edge rounding and increase tool life. Using the right media can give a surface accuracy of 0.1 ^im. This is extremely important for...

Open the catalog to page 2

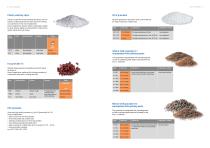

Stainless steel media No material is removed during finishing, only smoothing and hardening take place. Area of application: polishing, mirror-finish polishing and pressure deburring of non-ferrous metals Wet grinding paste Increases the abrasive effect of all types of grinding media. Also for roughening blunt grinding media. Further sizes on request Spherical zirconia No material is removed during finishing, only smoothing and hardening take place. Material: zirconia Area of application: polishing, mirror-finish polishing and pressure deburring of non-ferrous and ferrous metals Compounds...

Open the catalog to page 3

Plastic polishing chips These are used for the dry polishing of jewelry. The consistency of their geometry prevents dust from forming, a crucial factor in this area of application. Area of application: jewelry industry, especially suitable for silver jewelry, highly recommended for hollow items, lobster clasps and curb chains. QZ W granulate Abrasive granulate in aluminum oxide, used mainly for the edge rounding of carbide tools. LFP 3 white fine polishing DFP white fine polishing Dry granulate TZ Defined-shape granules in polyethane with SiC added as abrasive. Area of application:...

Open the catalog to page 4

Corn granulate M 4 impregnated with PP 02 polishing powder This granulate is impregnated with a special polishing powder so that no polishing additive needs to be added for the first 3 - 4 batches. Walnut shell granulate H 3 impregnated with PP 01 polishing powder This granulate is impregnated with a special polishing powder so that no polishing additive needs to be added for the first 3 - 4 batches. Walnut shell granulates can also be supplied unimpregnated (walnut shell granulate H 0). This granulate must be impregnated with a grinding or polishing paste before first use. Dosage: 2 - 3...

Open the catalog to page 5

Dry grinding paste Polishing powder These dry grinding pastes are mainly used in conjunction with H 2/... and M 2/... granulates in the dry finishing process. The rates of stock removal are considerably lower than with wet grinding media. These polishing powders are mainly used in conjunction with H 1/.. and M 1/.. granulates in the dry finishing process. They give high-quality, smooth surfaces with a very bright finish. Polishing powders are always used together with a grinding oil or grinding grease such as HL 11 or HL 7. Grinding oils Adhesive oils are used in conjunction with H/.. and...

Open the catalog to page 6

Precision finish demands WHERE WE LIVE, QUALITY HAS A LONG TRADITION Founded in 1996, OTEC has quickly established itself as the market’s technology leader by developing new machine concepts, inventions and improvements. OTEC supplies machines which are carefully tailored to the needs of specific industries and which are truly impressive in terms of cost-effectiveness, handling and precision and which are far superior to conventional systems. Around 120 members of staff are employed at the company‘s headquarters in Southern Germany. A global sales network ensures excellent worldwide...

Open the catalog to page 7All OTEC Präzisionsfinish GmbH catalogs and technical brochures

-

FLOW SEPARATION-FS SERIES

2 Pages

-

EPAG Flex modular

2 Pages

-

ECO, EF SERIES

7 Pages

-

CF & EPAG SERIES

8 Pages

-

SERIE CF ELEMENT

2 Pages

-

MASS FINISHING MACHINES

14 Pages

-

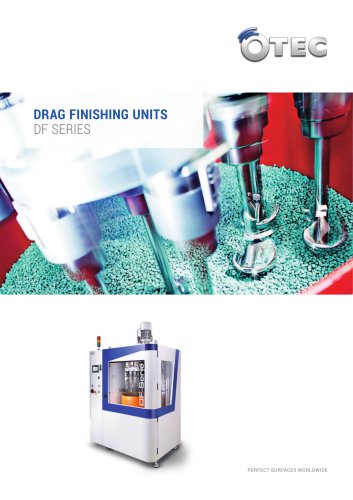

DRAG FINISHING UNITS DF SERIES

14 Pages

-

STREAM FINISHING UNITS SF SERIES

16 Pages