Catalog excerpts

Precision finish demands PERFECT SURFACES THROUGH MASS FINISHING OVERVIEW

Open the catalog to page 1

Disc finishing Mass finishing process, in which a rotating base plate sets workpieces and granulate in motion in a toroidal stream. The very intense finishing effect is up to 20 times more efficient than conventional vibrators. Especially suitable for: small parts, large quantities of bulk goods Drag finishing In the drag finishing process, the workpieces are clamped in holders and dragged at high speed in a circular motion through a process drum containing grinding or polishing granulate. This generates contact pressure between the workpiece and the media, which produces perfect results in...

Open the catalog to page 2

PERFECT RESULTS For a perfect finish, the right choice of mass finishing machine, abrasive media and finishing process are absolutely critical. The resulting perfect surface depends on many different parameters. Surface finished on a CNC grinding machine Ra: 1.23 pm, Rz: 7.9 pm Surface after finishing in a DF machine Ra: 0.01 pm, Rz: 0.1 pm magnified 125 times Edge rounding of a cutting tool Material: tungsten carbide Finishing time: 6 minutes o Three-fold increase in tool life DF Series Deburring gear and cog wheels, rounding and smoothing tooth faces Finishing time: 2 minutes o Up to 5...

Open the catalog to page 3

Rounding the cutting edges of cutting and stamping tools Material: tungsten carbide Very smooth surfaces at the cutting edge, e.g. Ra 0.05 µm Considerable increase in tool life SF Series Deburring, rounding and smoothing of a camshaft Process: PULSFINISH® Deburring, rounding and smoothing in approx. 60 seconds Ra before 0.4 µm, after 0.09 µm Maschineserie SF PULSFINISH® Mirror-finish polishing of a knee joint Before: line ground After: absolutely scratch-free Ra values up to 0.01 µm DF Series Polishing of workpieces made from ceramic and plastic materials Material: ceramic Very smooth,...

Open the catalog to page 4

WHERE WE LIVE, QUALITY HAS A LONG TRADITION Founded in 1996, OTEC has quickly established itself as the market’s technology leader by developing new machine concepts, inventions and improvements. OTEC supplies machines which are carefully tailored to the needs of specific industries and which are truly impressive in terms of cost-effectiveness, handling and precision and which are far superior to conventional systems. Around 120 members of staff are employed at the company‘s headquarters in Southern Germany. A global sales network ensures excellent worldwide support, and world beating...

Open the catalog to page 5

MACHINE TYPES SF Series Separating Units SF PULSFINISH® DF CF ECO / EF ECO-Maxi / HV 20 SEPARAČNÍ JEDNOTKY MÉDI

Open the catalog to page 6

THE SF SERIES The SF machines were developed for applications for which no satisfactory process previously existed, and which call for the highest possible surface qualities even in the finest detail. Very fine surface qualities with roughness values of only Ra < 0.05 µm can be obtained in the tiniest of flutes or grooves. SF machines are based on the principle of the stream finishing process. Highlights Very short finishing times for deburring, edge rounding and polishing Controlled sequence of movements, easy to automate When more than one tool holders are used, workpieces can be changed...

Open the catalog to page 7

PULSFINISH® THE CF SERIES PULSFINISH® was specially designed for the requirements of in-line productionloose in large Machines in the CF series are suitable small workpieces. These are finished in the automotive industry and the modern tool making industry. The machine features the innovative new pulse quantities in a process drum and include items such as jewelry and precision cut, turned, milled drive system. parts. CF machines are based on the principle of theof large in-line process and are and stamped This enables the extremely stringent requirements disc finishing production in terms...

Open the catalog to page 8

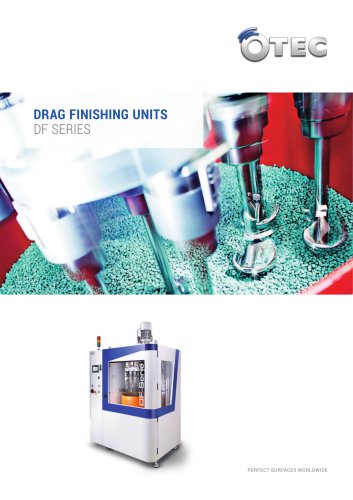

THE DF SERIES The DF machines enable the very best results to be obtained in an extremely short time – in the form of precision edge rounding, smoothing or mirror-finish polishing of a quality equivalent to that obtained by manual polishing. These very compact and economical machines are used mainly in the toolmaking and medical industries. DF machines are based on the principle of the drag finishing process. Highlights Edge rounding of cutting tools (much longer tool life) Smoothing and polishing (better flow properties, lower cutting forces) Removing droplets (better chip flow) Deburring...

Open the catalog to page 9

THE ECO-MAXI CF SERIES SERIES / HV 20 Machines in the CF series are suitable for small workpieces. These are finished loose in large quantities in a process drum and include items such as jewelry and precision cut, turned, milled The ECO-Maxi Series (basic, magnetic, wet, dry) and stamped parts. CF machines are based on the principle of the disc finishing process and are designed for dry, wet or oil finishing, depending on the type. Either everything in just one machine, as a modular base unit (ECO-Maxi „basic“) for all three process types or as dedicated models for just one process each...

Open the catalog to page 10

THE ECO / EASY FINISH SERIES ECO / EF series is specially designed for wet finishing. These machines are inexpensive to buy and maintain and are ideally suited to deburring turned and milled parts. They are available as benchtop units ECO 9/18 or as free-standing machines Easy Finish 9/18/32. ECO / EF machines are based on the principle of the disc finishing process. Technical features The ECO / EF series uses a patented gap adjustment system. This enables even thin workpieces with a thickness of 3 mm and over to be finished without becoming lodged in the gap. The patented quick adjustment...

Open the catalog to page 11

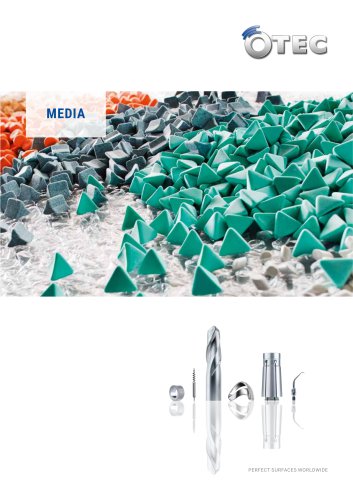

THE ECO-MAXI PERFECT SERIES / HV 20 SURFACES For each process, wet or dry, there is the The ECO-Maxi Series (basic, magnetic, wet, dry) corresponding media, the key to perfect results. Either everything in just one machine, as a modular base unit (ECO-Maxi „basic“) for all three process types or as dedicated models for just one process each (ECO-Maxi “magnetic“, ECO-Maxi “wet” and ECO-Maxi “dry”). The modular concept of the ECO-Maxi therefore makes it ideal for small-scale series production. Areas of application Removing grinding marks Improving the surface to a hand-finish quality Core...

Open the catalog to page 12All OTEC Präzisionsfinish GmbH catalogs and technical brochures

-

FLOW SEPARATION-FS SERIES

2 Pages

-

EPAG Flex modular

2 Pages

-

ECO, EF SERIES

7 Pages

-

CF & EPAG SERIES

8 Pages

-

SERIE CF ELEMENT

2 Pages

-

Media

7 Pages

-

DRAG FINISHING UNITS DF SERIES

14 Pages

-

STREAM FINISHING UNITS SF SERIES

16 Pages