Catalog excerpts

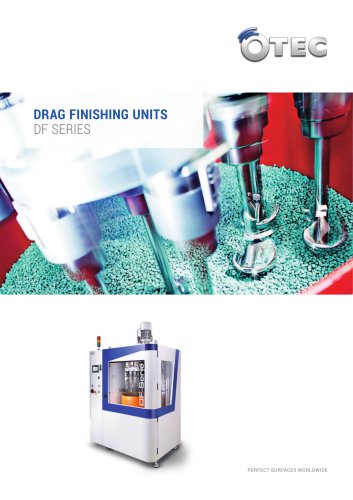

DRAG FINISHING UNITS DF SERIES PERFECT SURFACES WORLDWIDE

Open the catalog to page 1

2 | THE DRAG FINISHING PROCESS OTEC: WE MAKE THE DIFFERENCE Polishing, deburring, rounding or smoothing: We build drag finishing systems to finish any surface quickly and affordably. From small series production to large-scale industrial manufacturing. DF knee joint Video about finishing knee joints The OTEC drag finishing process is predestined for the finishing of large or heavy workpieces which cannot be finished in bulk. The workpieces are clamped in rotating holders and dragged through the process media at high speed. The high contact pressure and relative velocity between the...

Open the catalog to page 2

DF Tools Video about finishing tools Tool holders Polishing improves resistance to corrosion Thread-cutting taps Polishing reduces cutting forces and wear Tableting punch Polishing the contact surface optimizes compacting and improves the quality of tablets Burs Rounding the cutting edges increases tool life

Open the catalog to page 3

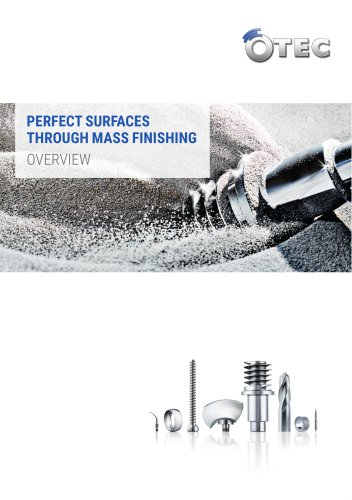

WE GET YOU TO THE FINISH WITH μ PRECISION OTEC-optimized surfaces ensure that workpieces fulfil the high requirements of our customers. The focus here is on the finish or properties of the surface. In series produc tion, reliably repetitive results and costeffectiveness deliver a real competitive edge. Residual burring and swarf from the manufacturing process on the edges and surfaces impair the quality of a workpiece. By choosing the right media and the right process, these blemishes can be removed to give trouble-free downstream finishing and better handling. Edges are generally rounded...

Open the catalog to page 5

WHERE QUALITY IS INSIDE, QUAL ITY COMES OUT With its DF series, OTEC offers a versatile range of drag finishing machines. Whether for small or large series production, every single ma hine fulfils the most demanding require c ments in terms of cost-effectiveness and precision. When you opt for an OTEC DF system, you are choosing unparalleled quality made in Germany – at a fair price. Top-quality materials guarantee long service life and a proven design concept ensures ergonomic and efficient handling. The extensive standard equipment supplied and the wide range of modular add-ons make each...

Open the catalog to page 6

GENUINE COMPO NENTS FOR A GENUINE SYSTEM Machine + holder + process + workpiece. The whole is more than the sum of the parts. In Our OTEC workpiece holders make a significant contribution to the perfect processing results obtained by the DF series. OTEC’s proprietary tool holders ensure that the workpieces are mounted as quickly and effectively as possible and considerably speed up batch processing. In recent years, we have designed over 100 different types of holder in close cooperation with our customers. In par ticular, optional features such as laser-operat ed immersion depth control...

Open the catalog to page 7

THE QUALITY SERIES FOR SE RIOUS QUALITY Ideally suited to finishing workpieces in small to medium production runs. The solution for finishing workpieces in large-scale industrial production. Drag finishing machine for grind ing and polishing workpieces in wet and dry media.

Open the catalog to page 8

DF-40/80 PHARMA series Specially developed to meet the requirements of the pharmaceuticals and food industries. Special machines Custom-built to your process requirements with our extensive experience and at a fair price.

Open the catalog to page 9

Output depending 7,5 on configuration (kVA) Holder positions 3/4 Adapter positions with 3/4/6 head

Open the catalog to page 10

WE REINVENT OURSELVES, JUST FOR YOU Example: customized machine: DF 5/330 with a drum diameter of 1100 mm Do you have exceptional requirements for which there is not yet a solution on the market? Speak to us. As the technology leader in innovative drag finishing machines, special solutions made to our customers’ specifications are our particular strength. We work closely with you to develop a highly customized solution, including the most suitable process. Our team will be pleased to advise you without any cost or obligation on your part and in absolute confidence. Call us: 07082 4911-20

Open the catalog to page 11

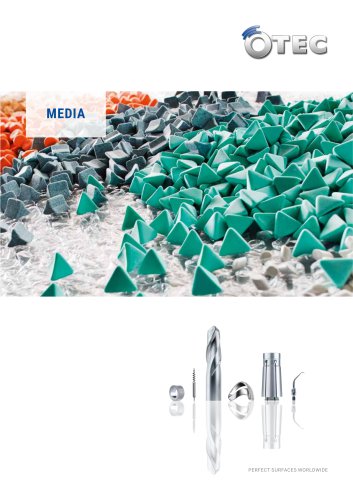

12 | PROCESS DEVELOPMENT AND MEDIA MACHINE AND PROCESS – THE DUAL SOLUTION Every workpiece is different. For a reproduc ible and efficient process which always results Our OTEC research lab offers you a professional service and can develop a process fine-tuned to your workpiece and your application. in a perfect surface, all relevant parameters are determined and documented in the lab. The measurement log shows the edge rounding in the μm range. After processing a sample, we first create a log documenting all process parameters. On the basis of this information, the details of stock...

Open the catalog to page 12

WHERE WE LIVE, QUALITY HAS A LONG TRADITION Founded in 1996, OTEC has quickly estabished l itself as the market’s technology leader by developing new machine concepts, inventions and improvements. OTEC supplies machines which are carefully tailored to the needs of specific industries and which are truly impressive in terms of cost-effectiveness, handling and precision and which are far superior to conventional systems. Around 120 members of staff employed at the company‘s headquarters in Southern Germany and a global sales network ensures excellent worldwide support and outstanding quality...

Open the catalog to page 14All OTEC Präzisionsfinish GmbH catalogs and technical brochures

-

FLOW SEPARATION-FS SERIES

2 Pages

-

EPAG Flex modular

2 Pages

-

ECO, EF SERIES

7 Pages

-

CF & EPAG SERIES

8 Pages

-

SERIE CF ELEMENT

2 Pages

-

MASS FINISHING MACHINES

14 Pages

-

Media

7 Pages

-

STREAM FINISHING UNITS SF SERIES

16 Pages