Catalog excerpts

WHERE WE LIVE, QUALITY HAS A LONG TRADITION SIMPLY BRILLIANT HIGH-TECH JEWELRY POLISHING Founded in 1996, OTEC has quickly established itself as the market’s technology leader by developing new machine concepts, inventions and improvements. OTEC supplies machines which are carefully tailored to the needs of specific industries and which are truly impressive in terms of cost-effectiveness, handling and precision and which are far superior to conventional systems. Around 100 members of staff are employed at the company’s headquarters in Southern Germany. A global sales network ensures excellent worldwide support and world-beating finishing processes at all times. OTEC Präzisionsfinish GmbH Heinrich-Hertz-Str. 24 · 75334 Straubenhardt · Germany Tel. +49 7082 4911-20 · Fax +49 7082 4911-29 · Email: info@otec.de www.otec.de

Open the catalog to page 1

2 | OTEC – YOUR PARTNER IN THE JEWELRY INDUSTRY We supply more than just machines. We supply reliably reproducible results. This is the combination of technology, process media, precisely coordinated parameters and above all – many years of experience. WE MAKE YOUR BUSINESS SHINE OTEC has been the leading partner for surface finishing in the jewelry industry since 1999. More than 5,000 customers worldwide – from small businesses to global players – put their We work closely together with you to decide which is the most cost-effective and most efficient solution. For classical jewelry...

Open the catalog to page 2

4 | OTEC – YOUR PARTNER IN THE JEWELRY INDUSTRY WE SHINE WHEN POLISHING IS DIFFICULT Even in combination with sensitive materials such as pearls, gemstones or enameling, highluster surfaces can be obtained with no risk to any of the components, and irrespective of the design of the workpiece. We love challenges. They motivate us to keep on developing and refining our machines and The newly developed electropolishing system puts a shine on previously inaccessible areas. This easily gives a much more detailed and brilliant finish to complex workpieces – without using any hazardous chemicals...

Open the catalog to page 3

6 | OTEC - YOUR PARTNER IN THE JEWELRY INDUSTRY OUR COLLECTION FOR YOUR PRODUCTION Whether you are looking for a stand-alone solution or want to set up a production line -the OTEC CF series will always have the right machine for demanding jewelry finishing in any batch size. All machines in the CF series work on the disc finishing principle whereby the workpieces are immersed in a drum-shaped container filled with grinding or polishing granulate and a disc in the base of the drum is made to rotate. The disc is separated from the wall of the container by means of an adjustable gap. The...

Open the catalog to page 4

GENTLE FINISHING IN INACCESSIBLE AREAS When it comes to polishing intricate details or inaccessible internal contours, electropolishing is the method of choice. The new OTEC EPAG Flexmodular polishing unit combines top quality with great cost-effectiveness. The EPAG Flexmodldar is an electropolishing unit for yellow, red and white gold, as well as for silver. This electropolishing unit enables filigree jewelry rings to be ground and polished in the shortest possible time. Intricate details remain intact and internal contours receive an excellent finish. Manual polishing is reduced to a...

Open the catalog to page 5

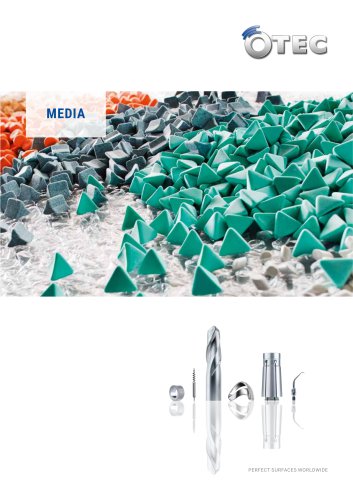

12 | OTEC - YOUR PARTNER IN THE JEWELRY INDUSTRY MANY VARIABLES FOR PERFECT RESULTS We find the right parameters for each task, and we supply the right ingredients for each process. From grinding pastes and powders, polishing media and granulates to ready-to-use compound solutions. The finished quality of any surface depends mainly on choosing the right process media for the machine being used. In each individual case, the process media is selected which is right for the specific workpiece in hand. Processes are divided into wet and dry finishing. In the case of wet finishing, a...

Open the catalog to page 6

14 | OTEC - YOUR PARTNER IN THE JEWELRY INDUSTRY Compounds Compounds are added to the disc finishing machines during the grinding process in order to produce clean, bright and non-corroded workpiece surfaces. With impact-sensitive workpieces, the compound creates a foam buffer between the workpieces and the abrasive media. Wood polishing chips Depending on whether grinding or polishing paste is added, wood polishing chips are suitable both for fine grinding and for polishing plastic, wood and horn. * available in various concentrations ** specially for the jewelry industry Dry polishing...

Open the catalog to page 7

16 | OTEC - YOUR PARTNER IN THE JEWELRY INDUSTRY Stainless steel media No material is removed during processing. The surface is merely smoothed and compacted. Used for: polishing, mirror-finish polishing and pressure deburring of precious metals. Spherical zirconia No material is removed during processing. The surface is merely smoothed and compacted. Further sizes on request. Electropolishing media GL 20: Polishing compound for gold PL 1: Polishing compound for silver RELIABLE SEPARATION The FS flow separation series from OTEC is the ideal solution for the fast and reliable separation of...

Open the catalog to page 8All OTEC Präzisionsfinish GmbH catalogs and technical brochures

-

FLOW SEPARATION-FS SERIES

2 Pages

-

EPAG Flex modular

2 Pages

-

ECO, EF SERIES

7 Pages

-

SERIE CF ELEMENT

2 Pages

-

MASS FINISHING MACHINES

14 Pages

-

Media

7 Pages

-

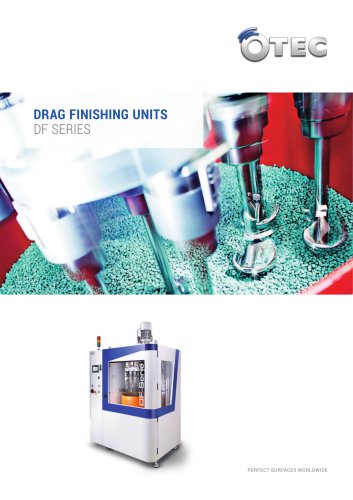

DRAG FINISHING UNITS DF SERIES

14 Pages

-

STREAM FINISHING UNITS SF SERIES

16 Pages