Catalog excerpts

TOOL COMMUNICATION

Open the catalog to page 1

To brighten the future of milling technology, which lays the foundation for the world’s manufacturing industry; we have reinforced our carbide end mill series. Zur Auffrischung der zukünftigen Frästechnologie, welche die Basis der weltweiten Produktions-Industrie bildet, haben wir unser Vollhartmetall-Fräsprogramm nochmals verbessert und erweitert. New coating WXL end mill series WXL - Neueste VHM Fräser Beschichtung Handle a wide range of materials and applications! Für eine große Anzahl an Materialien und Anwendungen The new WXL coating excels in lubricity and wear resistance to...

Open the catalog to page 2

©New WXL coating development concept Die neue WXL Entwicklungsziele This coating has been developed to improve performance in a wide range of materials including nonferrous materials, mild steels, and refined steels up to 50 HRC. Its' stable performance remains consistent in both wet and dry applications. It is intended for a wide range of cutting conditions, from low speed / reduced cutting force applications to high speed / large cutting force applications. Therefore, it ensures stable performance with ball end mills, which are susceptible to cutting speed fluctuations. Diese neue...

Open the catalog to page 3

Cutting conditions • Offers three times the durability in both dry or wet applications! • Drei mal längere Lebensdauer in Trocken- und Nassbearbeitung. Work Material Milling Speed Milling Method Pocket Milling Taschenfräsen Projection Length Flank Wear at Ball Nose Freiflächenverschleiß an der Kugel Vertical Machining Center Vertikales BAZ Pockets (psc) - Taschen (st) After Pockets Milling Pocket Taper Angle Taschenschräge Pocket Corner R Tachenradius Work Material Milling Speed Milling Method Pick Milling Zeilenfräsen Water-Soluble (Emultion) Emulsion Wasserlöslich 0,16 Flank Wear at Ball...

Open the catalog to page 4

| Cutting conditions - Schnittwerte • The WXL Series handles a wide range of materials! When working in copper, its durability level is three times greater than TiAIN coating. Also, it ensures stable miling in hard materials. • Die WXL Serie decken einen groGen Bereich von Werkstoffen ab. Bei der Bearbeitung von Kupfer, liegt die Standzeit drei mal hoher als bei TiAIN Beschichteten Werkzeugen. WXL-EBD C1100 | Cutting conditions - Schnittwerte WXL-EBD Milling in C1100 - WXL Bearbeitung C1100

Open the catalog to page 5

MILLING - FRASEN - FRESATURA - FRAISAGE * ALTA PERFORMANCE Applications - Anwendungen - Applicazioni - Applications

Open the catalog to page 6

MILLING - FRASEN - FRESATURA - FRAISAGE High speed regular milling - HSC Standardfrasen - WXL-EBDFresatura alta velocita standard - Fraisage UGV standard Work material Werkstoff Materiale Matiere a usiner 1. Use a rigid and precise machine and holder. 2. Use a suitable cutting fluid with high smoke retardant properties. 3. Refer to the table above to set the milling conditions in accorance with the actual situation. * When the length of tool extension from the machine is long, reduce the speed and feed. ** When B is less than 15°, speedand feed in the above table can be increased 1,5 to...

Open the catalog to page 7

MILLING - FRASEN - FRESATURA - FRAISAGE Ball nose end mills - Miniatur-Kopierfraser - Microfrese sferiche per nervature - Microfraises hemispheriques * HIGH PERFORMANCE * HIGH PERFORMANCE * ALTA PERFORMANCE ssssmn * HAUTE PERFORMANCE WXL-LN-EBD No numerical value means no interference with workpiece. Wenn kein Wert eingetragen ist, gibt es Keine Beruhrung mit dem Werstuck.

Open the catalog to page 8

MILLING - FRASEN - FRESATURA - FRAISAGE Ball nose end mills - Miniatur-Kopierfraser - Microfrese sferiche per nervature - Microfraises hemispheriques

Open the catalog to page 9

MILLING - FRASEN - FRESATURA - FRAISAGE Ball nose end mills - Miniatur-Kopierfraser - Microfrese sferiche per nervature - Microfraises hemispheriques

Open the catalog to page 10

MILLING - FRASEN - FRESATURA - FRAISAGE Ball nose end mills - Miniatur-Kopierfraser - Microfrese sferiche per nervature - Microfraises hemispheriques

Open the catalog to page 11

MILLING - FRASEN - FRESATURA - FRAISAGE Ball nose end mills - Miniatur-Kopierfraser - Microfrese sferiche per nervature - Microfraises hemispheriques Applications - Anwendungen - Applicazioni - Applications

Open the catalog to page 12

MILLING - FRASEN - FRESATURA - FRAISAGE Conditions - Schnittwerte - Condizioni - Conditions High speed regular milling - HSC Standardfrasen - WXL-LN-EBD Fresatura alta velocita standard - Fraisage UGV standard Work material Werkstoff Materiale Matiere a usiner

Open the catalog to page 13

MILLING - FRASEN - FRESATURA - FRAISAGE Conditions - Schnittwerte - Condizioni - Conditions WXL-LN-EBD High speed regular milling - HSC Standardfrasen - Fresatura alta velocita standard - Fraisage UGV standard WXL OSG Europe : www.osgeurope.com WXL08R07a Work material Werkstoff Materiale Matiere a usiner

Open the catalog to page 14

MILLING - FRASEN - FRESATURA - FRAISAGE Conditions - Schnittwerte - Condizioni - Conditions High speed regular milling - HSC Standardfrasen - WXL-LN-EBD Fresatura alta velocita standard - Fraisage UGV standard Work material Werkstoff Materiale Matiere a usiner

Open the catalog to page 15

MILLING - FRASEN - FRESATURA - FRAISAGE WXL-LN-EBD High speed regular milling - HSC Standardfrasen - Fresatura alta velocita standard - Fraisage UGV standard Work material Werkstoff Materiale Matiere a usiner 1. Use a rigid and precise machine and holder. 2. When machining carbon steels or hardened steels, using MQL (Minimum Quantity Lubrication / mist coolant) is recommended. 3. Please adjust conditions based on machining accuracy, machining shape and machining path. 4. When using a tool with a diameter of 0 0.5 (R0.25) or less, or an L/D (effective length/ tool diameter) ratio grater...

Open the catalog to page 16

MILLING - FRASEN - FRESATURA - FRAISAGE Conditions - Schnittwerte - Condizioni - Conditions High-speed light milling - HSC Schlichtfrasen WXL-LN-EBD Fresatura alta velocita - Fraisage UGV Work material Werkstoff Materiale Matiere a usiner

Open the catalog to page 17

MILLING - FRASEN - FRESATURA - FRAISAGE Conditions - Schnittwerte - Condizioni - Conditions WXL-LN-EBD High-speed light milling - HSC Schiichtfrasen Fresatura alta vclocita - Sraisagc UGV WXL OSG Europe : www.osgeurope.com WXL08R07a Work material Werkstoff Materiale Matiere a usiner

Open the catalog to page 18All OSG EUROPE LOGISTICS catalogs and technical brochures

-

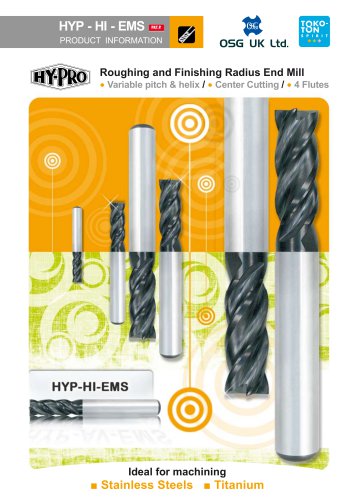

HY-PRO Planet Cutter

16 Pages

-

NC Planet Cutter® for Steel

6 Pages

-

X-Performer Forming Taps

4 Pages

-

Chip Control - Series

12 Pages

-

Hypro Carb Holders

4 Pages

-

HSS Extra-Long Drills

12 Pages

-

Carbide Straight Reamers

4 Pages

-

FX-Carbide Drills

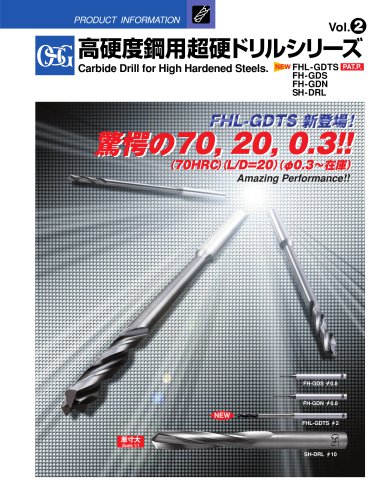

16 Pages

-

HSS Nexus Drills

8 Pages

-

Special Taps 2007

20 Pages

-

Aerospace Industry

16 Pages