Website:

OSG EUROPE LOGISTICS

Website:

OSG EUROPE LOGISTICS

Catalog excerpts

PRODUCT INFORMATION NEW PRICES - 2009 HSS NEXUS DRILL ! New coating, high speedy long toot life HSS drill !

Open the catalog to page 1

Utilizes the HSS-specific WDI ™ Coating The WDI TM Coating inhibits wear on the margin ! Achieves long tool life in high-speed machining ! A high helix and unique flute form design The high helix (35°- 40°) and unique flute form design reduces machining heat and work hardening. Chips are broken into small pieces even in stainless steels and copper alloys, making nonstep drilling of 3-4 D holes possible. Premium substrate Using premium grade vanadium high speed steel as the substrate increases toughness, preventing chipping that is often associated with machining stainless steels. The...

Open the catalog to page 2

OSG’s HSS drills are ideal for a wide range of machining applications. There are an abundance of sizes in inventory to meet with individual needs. ■ NEXUS Drills and EX-SUS Drills cutting conditions based on materials m/min Drilling Speed For Improved efficiency in High-speed applications... Nexus Drills are recommended. For stable low-to mid-speed drilling... EX-SUS Drills are recommended. Stainless Steel Mild Steel Work Material Aluminum Alloy Casting A tool life comparison between the high-speed NEXUS Drill and a competitor (dia 6mm drill, 18 mm hole depth). Eco-Friendly Commitment...

Open the catalog to page 3

Competitor A Competitor B Competitor C Wear Amount

Open the catalog to page 4

Flute Face Flute Face

Open the catalog to page 5

Dimensions Stub Type Available from March 2009 Four Facet point l L ● Drill Diameter Torelance h8 The drill diameter tolerance is 0 - 0,015 is for sizes of 0,01mm increments. Unit:mm

Open the catalog to page 6

NEXUS-GDS - NEXUS-GDR 1. The indicated speeds and feeds are for drilling with water soluble coolant. 2. The most suitable cutting fluid is water-emulsifiable high density oil (less than 10 times dilution) 3. When drilling cast surface and black (ie.not ground surface), reduce drilling speed by 20%. 4. For drilling depth>3D.reduce drilling speed (using the table below). 5. Step feeding is required for drilling depth>4D. 6. When using non-water soluble coolant or water-emulsifiable (over 10 times dilution), reduce the drilling speed by 20%. WORK MATERIAL The contents of this catalogue are...

Open the catalog to page 8All OSG EUROPE LOGISTICS catalogs and technical brochures

-

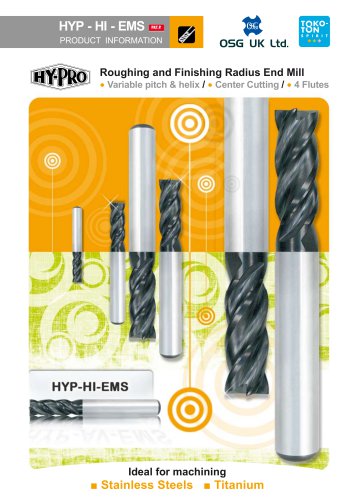

HY-PRO Planet Cutter

16 Pages

-

NC Planet Cutter® for Steel

6 Pages

-

X-Performer Forming Taps

4 Pages

-

Chip Control - Series

12 Pages

-

Hypro Carb Holders

4 Pages

-

HSS Extra-Long Drills

12 Pages

-

Carbide Straight Reamers

4 Pages

-

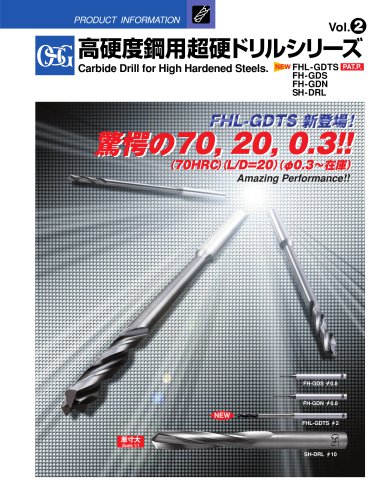

FX-Carbide Drills

16 Pages

-

Special Taps 2007

20 Pages

-

New coating WXL end mill series

24 Pages

-

Aerospace Industry

16 Pages