Catalog excerpts

NOW EVEN MORE COMPETITIVE! HSS EXTRA LONG DRILLS 10 D, 15 D and 20 D ! HSS drills without coolant-holes can achieve frOo 1 OxD up to 20xD !

Open the catalog to page 1

Newly developed flat flute (Pat. P.) Newly developed low-resistance thinning (Pat. P.) TDXL features four newly developed technologies including three patents pending! Newly developed WXL coating for drills Newly developed compound flute lead construction (Pat. P.) New flute shape (Pat. P.) dramatically improves chip evacuation ! It is capable of non-step drilling from 10 D up to 20xD! Highly rigid, wide flutes with smooth curves Newly developed flat flute (Pat. P.) ■ Chip shape when drilling S50C Short, broken pieces Long, curly chips

Open the catalog to page 2

The newly developed thinning (Pat. P.) exhibited half the thrust resistance(in-house comparison)! ■ Thrust Sharp and low-thrust new thinning form TDXL TDXL was tested at a depth of 20xD Competitor The competitor's product with a shorter flute was tested at a depth of 15xD Newly developed compound flute lead construction (Pat. P.) ■ Stable drilling power (spindle amperage) Competitor 283 The newly conceived flute design widens in the middle, significantly improving chip evacuation. Thanks to this, it is capable of non-step drilling of up to 20xD. New coating improves durability ! The newly...

Open the catalog to page 3

■ Compared to the competitor's product, the maximum thrust value is stable. Durability is 1,8 to 3 times greater !! Tool Tool runhout under 2^m Drill for pilot hole OSG UK: www.osg-uk.com

Open the catalog to page 4

Torque increased at about 20xD Competitor B Thrust fluctuations Torque increased at about 12xD TDXL After Drilling 392 Holes Competitor A After Drilling 112 Holes Competitor B After Drilling 112 Holes

Open the catalog to page 5

■ Compared to the competitor's product, our drill was capable of drilling an overwhelming number of holes !! Drill for pilot hole

Open the catalog to page 6

• Tool Material • SurfaceTreatment For 10D operation HSS-Co WXL Coating

Open the catalog to page 7

15D Operation Type Dimensions ● Tool Material ● SurfaceTreatment

Open the catalog to page 8

• Tool Material HSS-Co • Surface Treatment WXL Coating

Open the catalog to page 9

Coolant Application Key Points Horizontal machining center Vertical machining center Deepest area Hole entrance at deepest area Hole depth midway point Hole entrance at hole depth midway point Drill entrance area Drill antrance area Allow the coolant to move along the drill if the discharge flow rate is low or the number of nozzles is too few. Hole entrance Hole area depth midway point Deepest area Hole entrance area If there are too few coolant nozzles is small, increase the amount of coolant and its discharge pressure and allow the coolant to move along the drill so that it is applied...

Open the catalog to page 10

FRÄSEN - MILLING Notizen - Notes

Open the catalog to page 11

1. The indicated speeds and feeds are for drilling with water-soluble oil. When using non-water soluble oil, reduce the drilling speed by 20-30%. 2.The most suitable cutting fluid is water-soluble oil (10-30 times dilution). 3. Refer to the "Coolant Application Key Points" for instructions on how to apply the coolant. 4.If chip evacuation becomes difficult during non-step drilling due to the type of work material or its annealed condition, perform step-feed drilling. In this case, we recommend the peck feed method in which the drill is retracted at a rate of approximately 100 times the feed...

Open the catalog to page 12All OSG EUROPE LOGISTICS catalogs and technical brochures

-

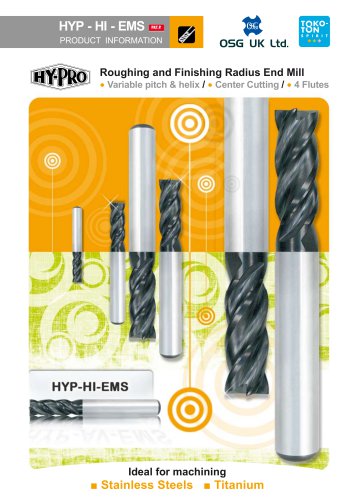

HY-PRO Planet Cutter

16 Pages

-

NC Planet Cutter® for Steel

6 Pages

-

X-Performer Forming Taps

4 Pages

-

Chip Control - Series

12 Pages

-

Hypro Carb Holders

4 Pages

-

Carbide Straight Reamers

4 Pages

-

FX-Carbide Drills

16 Pages

-

HSS Nexus Drills

8 Pages

-

Special Taps 2007

20 Pages

-

New coating WXL end mill series

24 Pages

-

Aerospace Industry

16 Pages