Website:

OSG EUROPE LOGISTICS

Website:

OSG EUROPE LOGISTICS

Catalog excerpts

Aerospace Industry High performance cutting tool solutions for the AEROSPACE

Open the catalog to page 1

Tool Communication ?K First Choice wffl) Good APPLICATION TITANIUM STAINLESS STEEL FTO-GDS / GDN Carbide drill SHR-DRL Carbide Drill FTO-GDXL Carbide Drill CAO-GDXL Carbide Drill D-GDN Carbide Drill E-series PMT-15 Taps V-Ti-Series PMT-15 Taps CC-SFT Series HSS-EV3 Taps AL Series HSS-EV3 Taps NEO-Series Carbide End Mill Cutting tools for the Aerospace industry

Open the catalog to page 2

The world of Aerospace manufacturing is a constantly evolving market, with more and more exotic ce manufacturing uring n evolving market, n et t er strength weight materials being used in order to give a higher strength to weight ratio. manufacturers a pr The challenge for all manufacturers supplying tooling for this market is to provide products that can onsistent c conta maintain a long and consistent tool life. This has been the goal of OSG and contained within this f newly e p products Aerospace p brochure are many of our newly designed products for the Aerospace sector. concentrate n...

Open the catalog to page 3

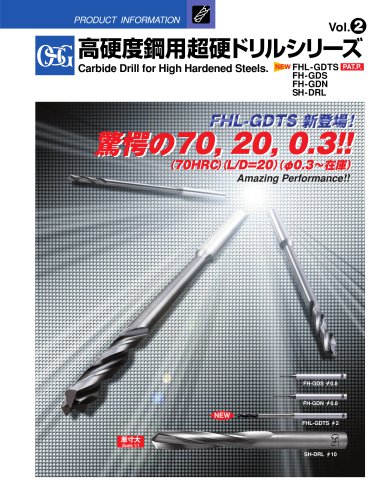

SUPER ALLOY Drilling Solutions for Super Alloy’s FTO-GDS / GDN Through Coolant Carbide Drill High performance through coolant carbide drill coated with OSG’s FX coating to give superior performance in Super Alloy’s. Technical Work Material Cutting Speed Hole Depth Ni50% Nickel Base Alloy Drill Diameter FTO-GDN (Normal Length) 3,0mm ~ 20,0mm. FTO-GDS (Stub Length) 2,8mm ~ 10,2mm Pecking / Steps Tool life judgement SHR-DRL Special Micro Grain Carbide Drill for Ultimate surface finish Micro grain class carbide drill for longer tool life, featuring a low helix design for higher rigidity, special...

Open the catalog to page 4

SUPER ALLOY Milling Solutions for Super Alloy’s Neo-Series, Variable Lead Carbide End mills , High performance coated carbide end mills with OSG’s new variable lead technology, c suppresses chattering allowing for outstanding milling performance in difficult to machine allow materials. Using the ideal cutting edge (po (positive edge form) for cutting difficult to machine materials, stable machining can be achieved machi Tool Work Material Milling Method Side Milling Milling Speed Milling Depth Water soluble Fluid (5%) Vertical Machining Centre (BT40) Exocarb Aero Rougher: TiALN Coated Carbide...

Open the catalog to page 5

TITANIUM Drilling Solutions for Titanium FTO-GDXL Through Coolant Carbide Drill High performance through coolant carbide drill coated with OSG’s FX coating to give superior performance in Titanium Alloy’s. NON-STEP DRILLING When deep-hole drilling with traditional methods, Cost effectiveness is hard to achieve. OSG has developed the FTO-GDXL , a revolutionary solid carbide coolant-hole drill capable of drilling up to 30 times drill diameter without a peck cycle. To achieve deep-hole drilling at high speeds and feeds, the FTO-GDXL utilises a micro-grain carbide construction, TiALN coating,...

Open the catalog to page 6

TITANIUM Tapping Solutions for Titanium V-Ti-Series Taps, SFT For Blind Holes and POT Taps for Through Holes Titanium alloys have historically been difficult to cut due to poor heat conductivity, strong alloying tendencies and work hardening characteristics. OSG’s V-Ti range is designed to overcome these difficulties and produce high quality and high precision threads. This is achieved by combining the optimum design features of tap material, coating technology, flute and thread geometry to enable swarf to be ejected in a highly efficient operation. Technical Sizes Work Material Hole size...

Open the catalog to page 7

STAINLESS STEEL Drilling Solutions for Stainless Steel NEXUS-GDR / GDS Next Generation HSS-EV3 Drill Series HSS drills with OSG’s WD1TM coating technology allowing for both high speed and long tool life in Stainless Steel applications NEXUS-GDS 1,0mm ~ 12,0mm In 0,1mm increments NEXUS-GDR 2,0mm ~ 12,0mm EX-SUS-GDR / GDS HSS-EV3 TiN Coated Drills The unique high helix flute form design reduces work generated heat, and work hardening. Premium grade vanadium high speed steel, with increased toughness to prevent chipping often associated with machining stainless steel. Non step drilling 3~4...

Open the catalog to page 8

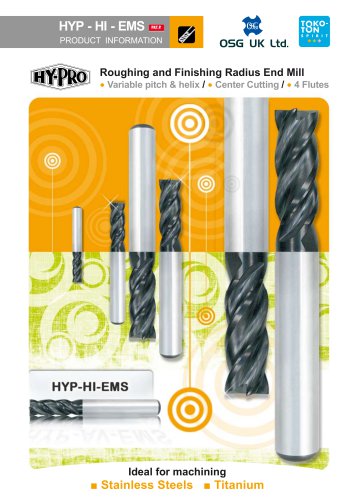

STAINLESS STEEL Milling Solutions for Stainless Steel UP-PHS: Vibration Resistant Multi Purpose Carbide End mills Carbide end mill featuring special geometry designed for cutting performance and vibration resistance, OSG coating technology for enhanced chip flow. Technical Metres Work Material Milling Speed Milling Method Projection length Water soluble Milling Depth Verical machining centre (BT40) Tool Life Judgement Machining conditions Machining conditions Helical Milling Contour Milling Contour line HYP-CR-HI-WEMS: Roughing and Finishing Carbide Radius End Mill. Carbide end mill...

Open the catalog to page 9

ALUMINIUM Drilling Solutions for Aluminium CAO-GDXL Through Coolant Extra Long Carbide Drill For Aluminium Capable of non step drilling up to 30X Diameter p g p Work Material Wear Amount (Drill) Aluminium Alloy Drill Diameter Drilling Speed Cutting Edge Flute Face Hole Depth Pecking / Steps Cutting Fluid Water Soluble Vertical machining centre After drilling 4.080 holes (277,4m), the wear amount on the drill is low. And inspite of drilling cross holes, no chipping was visible. Tapping Solutions For Aluminium AL-Series Taps, SFT For Blind Holes and POT Taps for Through Holes AL-Series...

Open the catalog to page 10

ALUMINIUM Milling Solutions For Aluminium. Exocarb Aero Blizzard: Carbide end mill series for Aluminium To compliment our range of metric tooling we are pleased to offer you our latest imperial carbide end mill series designed exclusively for the aerospace industry EXOCARB AERO EXOCARB® AERO™ PCD (Polycrystalline Diamond) Cutting Tools For Aluminium PCD Special Tools (Made to order) Polycrystaline Diamond tooling ideal for Aluminium applications. 3-4 week lead time with PCD tip and solid carbide body. Special form, Multiple flutes 2,3,4,6 & 8, Step Tools, Spot facing cutters and so on.....

Open the catalog to page 11

CFRP Drilling Solutions for CFRP (Carbon Fibre Reinforced Plastic) CFRP Diamond coated carbide drill OSG The drilling of composite materials is becoming more common and there are various manufacturers designing and producing drills for these applications. However only OSG can offer exceptional drill performance and tool life. Our drill design benefits from a high helix angle and high rake angle to produce a lower cutting force, together with our special drill point technology and patented smooth diamond coating. Allowing us to produce what we believe to be the best drilling solution for...

Open the catalog to page 12All OSG EUROPE LOGISTICS catalogs and technical brochures

-

HY-PRO Planet Cutter

16 Pages

-

NC Planet Cutter® for Steel

6 Pages

-

X-Performer Forming Taps

4 Pages

-

Chip Control - Series

12 Pages

-

Hypro Carb Holders

4 Pages

-

HSS Extra-Long Drills

12 Pages

-

Carbide Straight Reamers

4 Pages

-

FX-Carbide Drills

16 Pages

-

HSS Nexus Drills

8 Pages

-

Special Taps 2007

20 Pages

-

New coating WXL end mill series

24 Pages