Catalog excerpts

© The helmet was programmed and produced by DAISHIN.

Open the catalog to page 1

What’s new in 2016.2? hyperMILL* 2016.2 offers even greater performance and is easier to use than previous versions. The new 3D plane level machining and further optimisations for 3D milling enable more efficient programming. Highlights such as the 5axis-optimised rest material roughing ensure extremely short calculation and machining times. 5axis tangent machining has been added to the hyperMILL* MAXX Machining performance package. In addition, hyperCAD*-S once again includes numerous highlights and new features. General HHiUHiu Optimised menu navigation 3 nHaiHiu TDM Systems interface...

Open the catalog to page 2

Highlight Optimised menu navigation hyperMILL® 2016.2 is even more user-friendly than before. A new shortcut menu ensures even simpler and faster programming. The menu windows are structured more clearly and feature new icons. ■ Visibility of toolpaths: The toolpath display can be switched on and off using a visibility icon. ■ Feature generation: Selected areas of a job, such as faces and contours, can be generated as a feature and reused in later jobs. ■ Feature machining: You can now manually sort selected geometries in a feature and arrange them as required. ■ Global clearance plane: You...

Open the catalog to page 3

Tool database TOOL Builder The new hyperMILL® TOOL Builder allows you to quickly and e asily create holders for machining in hyperMILL®. An intuitiveto-use wizard allows you to directly import tool holder data from supplier catalogues in IGES or STEP format. The holders, extensions and turning tool holders generated can be assembled into an NC tool in the hyperMILL® tool database. All components are fully checked for collisions. This way, tool holders and extensions for milling can be imported to hyperMILL® with the original data from the supplier. hyperMILL® millTURN tools such as...

Open the catalog to page 4

Stop surfaces for drill holes By selecting stop surfaces, you can set a limit on the depths of individual drill holes or exclude these from machining altogether. Benefit: Easier exclusion of drill holes, greater safety, more efficient feature and macro programming. 2D contour milling on 3D models A new feature for feedrate checking allows the feedrate to be adapted specifically for individual contour elements. You can define the feedrate for individual contours or specific segments on a contour. The ‘Edge control’ option allows the feedrate to be adapted automatically to the tool and...

Open the catalog to page 5

Helical drilling The ‘Edge control’ option enables the feedrate to be adjusted automatically depending on the ratio between the tool diameter and hole diameter. This prevents the machining feedrate from becoming too high. Ø 16 m F: 40 m 0 Fre : 1 mm/min al . 12 mm /min . Benefit: Protects the tool, simple programming, increased safety. 3D free path milling An ‘Auto’ option to automatically orient tools to the left or to the right of the contour has been added to the Tool position panel in this cycle. Benefit: User-friendly, better automation capacity. 3D plane level machining This new...

Open the catalog to page 6

3D Z-level finishing A ‘Maximum stepdown’ option has been added to the cycle. In steep areas, you can limit the maximum vertical stepdown in the scallop height infeed mode. Benefit: Increased safety, avoids tool breakage. Path filleting for inner corners in flat and steep areas can now be defined via a radius. Benefit: Protects the tool. 3D profile finishing The new ‘Parallel stepdown’ feature allows you to adapt the vertical stepdown to the material height. Multiple infeeds on the offset component contour ensure that the material removal rate is even and consistent. Roughing and...

Open the catalog to page 7

hyperMILL® MAXX Machining Performance, Performance, Performance Speed is more crucial than ever these days. This is why OPEN MIND developed hyperMILL MAXX Machining, the comprehensive high-performance solution for roughing, finishing and drilling. Trochoidal tool paths ensure extremely fast material removal. Innovative strategies for barrel cutters allow for finishing in record time. Milling tools tilted in the cutting direction can quickly and easily drill holes and open pockets in hard material without the need for a predrilled hole. These unique solutions from OPEN MIND save enormous...

Open the catalog to page 8

Time savings for roughing efficient surfaces n ool friendly T n imple to program S n erfect P Time savings for finishing Process safety POSSIBLE APPLICATIONS: and mould manufacturing Machining n Aerospace n Automotive n Motor sports n Energy industries n

Open the catalog to page 9

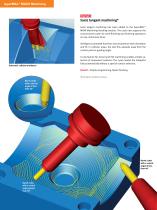

hyperMILL® MAXX Machining 5axis tangent machining* 5axis tangent machining has been added to the hyperMILL® MAXX Machining finishing module. The cycle now supports the conical barrel cutter for semi-finishing and finishing operations on any continuous faces. Intelligent automated functions ensure optimum tool orientation and fit. In collision areas, the tool tilts upwards away from the contact point or guiding angle. Automatic collision avoidance A new feature for Z-level and ISO machining enables simple selection of component surfaces. The cycle creates the toolpaths fully automatically...

Open the catalog to page 10

Conical interpolation The ‘Fast movement optimised’ option allows tools to be posi tioned around the pole in conical movements. This prevents singularities and generates simultaneous 5axis movement. Most machine tools can carry out this movement much more dynamically. Benefit: Shorter machine times, movements are easier on the machine tool. 5axis swarf cutting with one curve The cycle supports two new tool types. n Barrel cutters: You can create optimal surface quality with large Conical barrel cutter stepovers using barrel cutters – especially conical barrel cutters. n reely definable...

Open the catalog to page 11

Info: hyperCAD®-S In a class of its own among CAD systems Only a high-end CAM developer can do CAD for CAM. With this in mind, OPEN MIND Technologies AG – known as an innovative pioneer – developed a new CAD system from scratch that is perfectly matched to hyperMILL . The system ® has its own 3D CAD kernel made by OPEN MIND. The result is a unique CAD system for CAM programmers that is very easy to learn and that vastly accelerates NC programming processes. hyperCAD -S fully exploits the performance offered by contemporary hardware systems to create digital manufactu® ring data. The...

Open the catalog to page 12All OPEN MIND TECHNOLOGIES AG catalogs and technical brochures

-

Volkswagen, Braunschweig

2 Pages

-

Tml Precision Engineering

3 Pages

-

Flexible Machining Systems

2 Pages

-

Polygona

3 Pages

-

SOFTWARE

5 Pages

-

hyperCAD®-S.

16 Pages

-

hyperMILL

8 Pages

-

hyperMILL®. Version 2017.1.

16 Pages