Catalog excerpts

Double-Column Machining Center [5-Face Machining]

Open the catalog to page 1

Double-Column Machining Center [5-Face Machining] A world-class double-column machining center NC synchronized control of cross rail vertical travel • Rapid traverse W axis: 3 m/min High speed action • Rapid traverse X axis: 15 m/min Y axis: 20 m/min Z axis: 15 m/min (double ball screw) Full-enclosure shielding Full machine length chip disposal The most versatile machine for all machining processes, from heavy cutting to high-accuracy finishing for die/mold jobs and large complex parts.Safe and comfortableFast and highly functional operating environment I Lots of attachment heads • Wide...

Open the catalog to page 2

Okuma double-column machining centers with highly rigid and accurate construction Stability and high-accuracy from the spindlehead ways A ram-type spindlehead for super rigidity With a cross section of 350 x 350 mm (13.78 x 13.78 in.) there's enough rigidity in the square ram-type spindlehead to handle any horizontal cut. Big parts machining expertise. This machine was engineered with Okuma’s field-proven experience of building in exceptional power, rigidity, and smooth operation to assure close tolerances over time and high production. The shudder free design means heavy-duty face milling...

Open the catalog to page 3

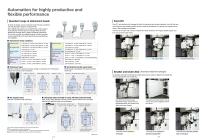

All kinds of shapes can be machined under the best conditions with the abundant variation of attachments. Many different processes can be performed continuously in auto operation with the auto tool changer (ATC) and auto attachment changer (AAC), greatly increasing productivity. For oil hole, air hole, thru-spindle coolant, oil mist, and dual contact specifications for each spindle (some specifications not available). One ATC arm performs the changes for both the horizontal and vertical spindles. And with the next tool brought to the standby position during a machining operation, the actual...

Open the catalog to page 4

High accuracy is enabled in normal factory environments. ■ Highly accurate control technology Thermo-Friendly Premium Specifications (Optional)* Thermo-Friendly Specifications (Optional) Thermo-Friendly Concept Spindle thermal deformation control technology Manageble Deformation — Accurately Controlled ■ Eliminate waste with the Thermo-Friendly Concept Thermal deformation from spindle rotation controlled with high accuracy. Thermo Active Stabilizer–– Construction for large machines (TAS-C2) Thermo Active Stabilizer––Table (TAS-T) Machine startup In addition to maintaining high dimensional...

Open the catalog to page 5

Okuma Intelligent Technology exhibits powerful effect on machine shop floors SERVONAVI Optimized Servo Control Achieves long term accuracy and surface quality ■ SERVONAVI AI (Automatic Identification) ■ SERVONAVI SF (Surface Fine-tuning) ● Reversal Spike Auto Adjustment Weight Auto Setting Cycle time shortened with faster acceleration Collision Avoidance System (Optional) Collision prevention Work Weight Auto Setting estimates the weight of the workpiece and fixture on the table and automatically sets the linear axis servo parameters, including acceleration, to the optimum values. Cycle...

Open the catalog to page 6

I High-speed machining • Spindle speed • Continuous cutting feed speed Fast contouring Hyper-Surface In addition to the features provided by Super-NURBS, Hyper-Surface automatically “corrects”, machining data to improve workpiece surface quality. High-accuracy machining • Thermo-Friendly Premium Specs (Optional) • Auto Attachment Head Compensation • Feed axis Deflection Auto Adjustment Powerful software for superb support of die/mold applications I Spindleheads with built-in attachment heads ■ Extension head ■ Universal index head With auto machining data compensation Crease marks and...

Open the catalog to page 7

I Many functions for a wider range of applications The Okuma NC makes it all possible. Things impossible on non-NC machines like User Task for example, are programmable like on a PC; making for a tremendous range of machining center applications. ■ Geometric change (Optional) 2 Programmable mirror image Mirror image operations can be command programmable as well as handled by switching. Using the points commanded by local coordinates, the drawings produced by a part program can be enlarged or reduced with this function. ■ User Tasks Variables can be used with arithmetic and branch commands...

Open the catalog to page 8

Spindle speed • Maximum non-adjacent tool size This is the maximum tool size when there are no tools on either side of a tool. * Note: Commercially available milling chucks may interfere with ATC arm and other _ _ , tools. Prior to use, confirm size dimensions with the tool manufacturer Note: Tools with a tool mass moment of 29.4 N-m or more cannot be used. With tools of 19.6 N-m or less, ATC can be used with high-speed operation. ■ Optional Accessories and Optional Specifications ■ Working ranges [When using an L150 extension head, a 90° angular head, and a 300-mm (11.81 in) tool] Unit: mm...

Open the catalog to page 9

I With revamped operation and responsiveness— ease of use for machine shops first! Smart factories implement advanced digitization and networking (IIoT) in manufacturing to achieve enhanced productivity and added value. The OSP has evolved tremendously as a CNC suited to advanced intelligent technology. Okuma’s new control uses the latest CPUs for a tremendous boost in operability, rendering performance, and processing speed. The OSP suite also features a full range of useful apps that could only come from a machine tool manufacturer, making smart manufacturing a reality. Smooth,...

Open the catalog to page 10

4. 32-tool ATCs have limitations on 25 or larger machines 5. [ ] show the values with specifications of 3,600/6,000/8,000/10,000 min-1 '6. X axis motor is 14 kW with 30 x 120, 35 x 120. *1. [ ] Numbers when extension head length is 250 mm. *2. [ ] for 6,000/8,000/10,000 min-1 *3. Decelerates at end of Y-axis travel.

Open the catalog to page 11

■ Elevating Crossrail (MCR-B -E) Dimensional Drawing Installation Drawing Air inlet 1,460 mm from floor 4,250 (167.32) 1,660 Cooling unit Hydraulic unit AAC/ATC Chip shield Safety plug Slush tank Power inlet 1,275 mm, 2,000 mm from floor Control cabinet Safety plug Chain Chip shield Safety fence Machine center * Please inquire for safety cover specifications, position and other details *2. Upper figures for 150-L extension head; lower figures for 250-L extension head *1. Upper figures for 4,000 min-1, 6,000 min-1; lower figures for 8,000 min-1 or faster spindles *3. Effective width between...

Open the catalog to page 12All OKUMA CORPORATION catalogs and technical brochures

-

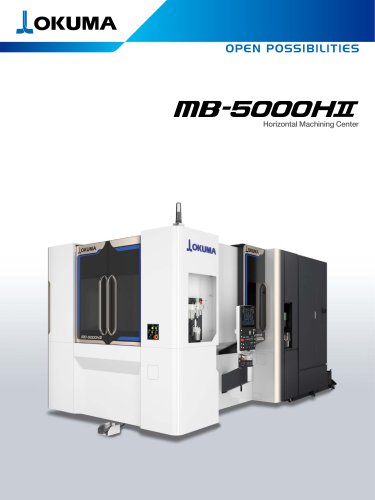

MB-5000HII

11 Pages

-

GENOS M560-V

11 Pages

-

LB2000 EX II

13 Pages

-

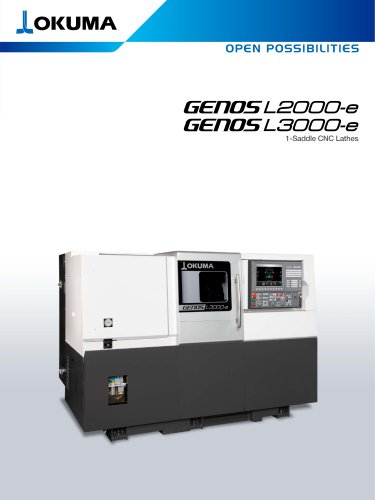

GENOS L2000/L3000-e

13 Pages

Archived catalogs

-

Aerospace Solutions

13 Pages

-

MACHINE TOOLS CATALOGUE

19 Pages

-

MULTUS BII

1 Pages

-

LT-EX Series

1 Pages

-

LU-S Series

1 Pages

-

LU Series

1 Pages

-

LU-EX Series

1 Pages

-

WHEEL MACHINES

1 Pages

-

Double Column

1 Pages

-

vertical_lathes_product_map

1 Pages

-

5_axis_machines_product_map

1 Pages