Catalog excerpts

OPEN POSSIBILITIES

Open the catalog to page 1

Transcending the Legendary LB Okuma's best and long-selling LB Series, the spearhead of a wide range of CNC lathes, now provides new functionality for today's requirements, breakthrough possibilities for the next generation, and more reliability to satisfy greater customer expectations. We are on a mission to "continuously enhance the LB to go beyond itself," and achieve productivity improvements linked to new strategic value chains. The machine against which all others will be measured The SPACE TURN LB EX II Series. Offering improved machining quality, speed, power and torque,...

Open the catalog to page 2

High accuracy specifications overall assure machining with high dimensional stability Highest Quality Thermo-Friendly Concept for unparalleled dimensional stability Slanted-box bed configuration with superior construction and rigidity The next evolution of the slanted-box bed construction that has been highly praised as a "rugged, Okuma-like construction" in the SPACE TURN series. The primary units of headstock and turret on a box bed is optimally placed for outstanding dimensional stability and high rigidity. Exhibits stable machining accuracy even in heavy cutting. Okuma’s Thermo-Friendly...

Open the catalog to page 3

Huge reduction in machining time with an original high power motor and faster machine movements Super Fast and Rigid Powerful motor on the spindle gives turning capacity of 2.7 mm2 Reduced operation time achieved with higher speed machine movements Spindle with a larger bearing internal diameter of ø100 mm can accommodate larger workpieces, and a turning capacity of 2.7 mm2 is achieved with a high-speed, wide-area full power motor. Stable, high quality machining, from heavy to high speed cutting. Z: 30 m/min (1,181 ipm) ● Spindle ● Turret tailstock rapids [Actual data*] 2 2 Cylindrical,...

Open the catalog to page 4

Greater efficiency with highest milling performance in its class and fast tool change times Reduced operation time achieved with higher speed machine movements Compact new PREX motor gives milling performance of 144 cm3 /min Compact, high-power, high-torque PREX motor also used for milling spindle of the multitasking V12 radial turret. This combined with a powerful, highly rigid bolt clamp system greatly increases multitasking speed. ●M rotate start/stop Milling capacity 144 cm3/min (Workpiece: S45C) [Actual data*] Chip volume 144 ø16 6-flute carbide end mill Cutting speed V: 100 m/min (328...

Open the catalog to page 5

Providing rich variation and optimum ease of use Extreme Versatility NC tailstock that shortens setup and automates center work is standard equipment Up to 10 pairs of tailstock positions can be set, enabling continuous machining of workpieces with 10 different lengths without setup. In addition, thrust can be switched between high and low without resetting the workpiece. (Tailstock thrust high/low switch: Optional) High accuracy positioning is also possible with a high speed linear guide employing a ball screw guide. ● Tailstock ● Rapid Complete multitasking with Y-axis functions One chuck...

Open the catalog to page 6

Okuma’s Intelligent Technology reduces operator burden With revamped operation and responsiveness— ease of use for machine shops first! Smart factories are using advanced digitization and networking (IIoT) in manufacturing to achieve enhanced productivity and added value. The OSP has evolved tremendously as a CNC suited to advanced intelligent technology. Okuma’s new control uses the latest CPUs for a tremendous boost in operability, rendering performance, and processing speed. The OSP suite also features a full range of useful apps that could only come from a machine tool manufacturer,...

Open the catalog to page 7

■ Optional Specs & Accessories Item _2 auto ranges (motor coil switching)_ I | 2 auto ranges (motor coil switching) ■ Chip conveyor types and application Various chip conveyors Note: Machine platform may be necessary depending on the type of conveyor.

Open the catalog to page 8

* Not available for T model specifications 1, *2. *3 cross-referenced for these two tables. * Select an ID oil-hole toolholder base (optional) for oil-hole drills and boring bars.

Open the catalog to page 9

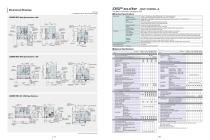

■ Tool Interference Drawings Z-axis travel 390 X-axis travel Z-axis Fixed cover right edge Radial mill/drill unit Turret rotation center Z-axis Fixed cover right edge X-axis travel 260 Spindle center Tailstock retract limit 191 Same with or w/o revolving center and release nut Turret rotation center 100 21 Tailstock retract limit 191 Axial mill/drill unit X-axis travel 80 130 50 Axial mill/drill unit Turret rotation center 240 170 Axial mill/drill unit Turret rotation center OD-V-S Radial mill/drill unit Tailstock retract limit Spindle center Spindle center Turret rotation center Z-axis...

Open the catalog to page 10

Floor Space Axial mill/drill unit Turret rotation center 240 170 Small machine footprint of 3.4 m2 for effective use of plant floor space. Tailstock retract limit 191 Axial mill/drill unit Chip bucket (Option) Coolant pump (side) ID-III-S Cross slide width 285 X-axis travel 413 Z-axis travel 550 Sub-spindle travel 595 Sub-spindle retract limit All travel range drawings shown are with standard spindle specs. This will differ with big bore and super big bore specs. 1,700 Space for rear chip conveyor removal 168 (336) 1,290 Coolant pump (rear) Hydraulic unit Power inlet approx. 1,770 mm above...

Open the catalog to page 11

Basic Specs Dimensional Drawings Unit: mm ( ) dimensions for H chip conveyor (High) LB2000 EXI (MY) Specifications x250 The Next-Generation Intelligent CNC ■ Standard Specifications External Input/Output and Communication Functions *1. NML: Normal, 3D: Real 3D simulation, OT-IGF: One-Touch IGF OTM: One-Touch M E: Economy, D: Deluxe *2. Real 3-D Simulation included *3. Engineering discussions required. Note: ATriangle items for M function (milling tool) machines only. Drawings shown are with standard spindle specs.

Open the catalog to page 12

When using Okuma products, always read the safety precautions mentioned in the instruction manual and attached to the product. ● The specifications, illustrations, and descriptions in this brochure vary in different markets and are subject to change without notice. Pub No. SPACE TURN LB2000 EX -E-(15a)-250 (Sep 2020) Oguchi-cho, Niwa-gun, Aichi 480-0193, Japan TEL: +81-587-95-7825 FAX: +81-587-95-6074 This product is subject to the Japanese government Foreign Exchange and Foreign Trade Control Act with regard to security controlled items; whereby Okuma Corporation should be notified prior...

Open the catalog to page 13All OKUMA CORPORATION catalogs and technical brochures

-

MCR-BIII

13 Pages

-

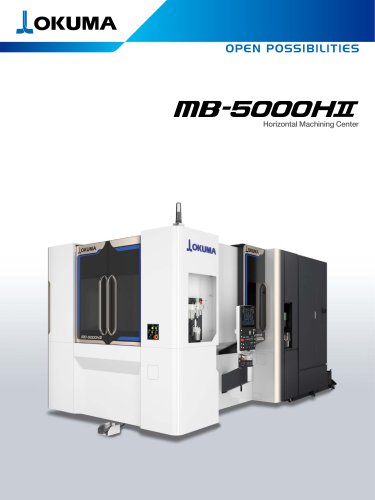

MB-5000HII

11 Pages

-

GENOS M560-V

11 Pages

-

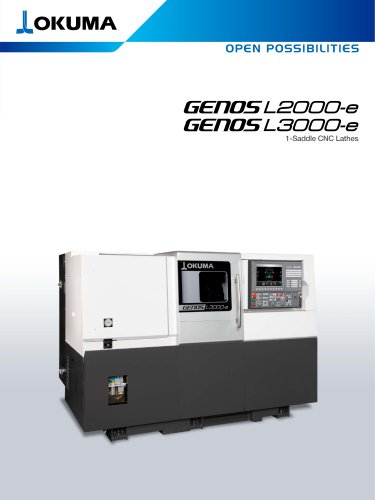

GENOS L2000/L3000-e

13 Pages

Archived catalogs

-

Aerospace Solutions

13 Pages

-

MACHINE TOOLS CATALOGUE

19 Pages

-

MULTUS BII

1 Pages

-

LT-EX Series

1 Pages

-

LU-S Series

1 Pages

-

LU Series

1 Pages

-

LU-EX Series

1 Pages

-

WHEEL MACHINES

1 Pages

-

Double Column

1 Pages

-

vertical_lathes_product_map

1 Pages

-

5_axis_machines_product_map

1 Pages