Catalog excerpts

Aerospace Solutions Global Support For over 115 years, Okuma has been investing in new technology, pioneering machine tool and control development, and has been helping manufacturers improve quality, enhance productivity and reduce costs. Our commitment to manufacturing extends around the world and our partnerships with industry suppliers and local distributors helps bring the best solutions to our customers. Okuma provides global support and service for manufacturers around the world. With over 3300 employees worldwide, and over one hundred distributor locations, Okuma is the team to partner with when it comes to engineering support and information. Outfitted with the finest CNC machine tools, Okuma’s technical centers (including the Aerospace Centers of Excellence in Paris, France and Charlotte, North Carolina) provide an opportunity for manufacturers to test and trial new equipment and processes, to improve productivity. Aerospace Center of Excellence—Charlotte, USA Aerospace Center of Excellence—Paris, France Okuma America Parc d'Activités des Chanteraines 7, rue du Commandant d'Estiennes d'Orves 92390 Villeneuve la Garenne France © Okuma America Corporation 2015 Okuma Technical Centre Paris Europark Fichtenhain A 20 47807 Krefeld Germany Okuma Europe GmbH 11900 Westhall Drive Charlotte NC 28278 USA

Open the catalog to page 1

Preventing machine stoppages from machine collisions Okuma technology supports the dreams of humankind From the beginning of time humans have had a desire to fly like the birds. It’s been more than a century since intelligence and technology combined to make this eternal dream come true. But development continues in the aerospace industry as safety, comfort and efficiency continue to evolve. And many aerospace suppliers rely on Okuma machine tools and technology to produce the high-quality, complex parts required to keep the iron birds flying. Collision Avoidance System IO Collision...

Open the catalog to page 2

Machining Navi See also okuma.co.jp/english/onlyone/process/index.html Okuma Single Source and Turnkey Solutions Maximizing machine tool performance Cost reduction—shorter cycle times and higher productivity—is required to compete in today’s global market. Machining Navi, with clear visuals of complex cutting conditions, is a breakthrough tool that enables the machine operator to navigate the machine and tool capabilities to their best performance levels. With Okuma's original advanced control technology and highly rigid structure, Okuma's highly functional machines, including 5-axis...

Open the catalog to page 3

Manageable Deformation—Accurately Controlled H For superb accuracies in "normal" manufacturing environments. The unique approach of "accepting temperature changes" Machining accuracy of the workpiece changes significantly due to ambient temperatures around the machine, heat generated by the machine, and heat generated in machining. The Thermo-Friendly Concept is the unique concept of "accepting" these temperature changes so that high accuracy can be achieved in normal factory environments with no special measures by the user. Machining dimensional change over time Innovating 5-axis...

Open the catalog to page 4

Innovation of 5-Axis Machining Volumetric Accuracy—Okuma Original Technologies Okuma Intelligent Technologies fully support the machining environment 5-Axis Auto Tuning System Taking 5-axis machining accuracy to the next level 5-A Automatic tuning with no geometric error, able to be carried out quickly and easily by anyone Five-axis machining accuracy is greatly affected by rotary axis misalignment and other “geometric errors” (see Figure 1). Okuma's 5-Axis Auto Tuning System measures geometric error using a touch probe and datum sphere, and performs compensation using the measured results...

Open the catalog to page 5

Reduced machining lead time through high quality and process-intensive machining Spindle tilt type 5-axis vertical machining center Spindle speed: Spindle tilt: A axis (spindle forward and back swing) 70° B axis (spindle left and right swing) 70° Rapid feedrate: X/Y axis 30,000 mm/min Z axis 24,000 mm/min Table load maximum mass: Suitable for powerful cutting of large, complex parts Okuma's superior processing machinery is perfect for high accuracy machined parts and special-shaped workpiece machining. Universal index head (B-/C-axis), NC-BC Universal head High quality, highly efficient...

Open the catalog to page 6

5-Axis Control Machining Center/ 5 Surface Machining Double Column Machining Center Innovating aircraft part machining Okuma's latest technologies 5-axis multitasking machine lineup providing solutions perfectly suited to the workpiece ENGINE PARTS Multi-sided, angled, curved surfaces universal heads capable of handling large complex shapes Engine Case Highly accurate 5-axis machining ENGINE PARTS 5-axis high speed blade machining Improved machining accuracy through one-chucking ENGINE PARTS Improved cutting conditions through use of optimal, non-interfering tools Reduced setup change time...

Open the catalog to page 7

5-Axis Vertical Multitasking Machines Double Column Multitasking Machines Highly efficient machining with outstanding machining capacity Beefy torque makes easy work even of difficult-to-machine material Two types of spindle, integral motor/spindle and gear head, are ready for use depending on the purpose, to achieve easy cutting from high-speed machining of non-ferrous material to high-speed machining of difficult-to-machine material. Process-intensive machining from OD turning to side milling No-interference turning with spindle set on angle Slide profile and fillet machining with 5-axis...

Open the catalog to page 8

Highly efficient machining with simultaneous 5-axis control + high-speed spindle From roughing to finishing, machining from plate blanks Workpiece: Material: Dimensions: Blank shape: dimensions 5-Axis Large Machining Center MILLAC 1000VH Spindle 10,000 min-1 specifications Simultaneous 5-axis control Plate Aluminum 840 x 370 x 30 mm 870 x 370 x 30 mm Highly Accurate 5-axis Multitasking L/rm- nsaoYB/L/Tm-saooYB B-axis control turret (Milling tool spindle) B-axis control: 0.001 orientation {Optional: NC-B axis [simultaneous 5-axis control]} Ram Head (Milling tool spindle) Large section ram of...

Open the catalog to page 9All OKUMA CORPORATION catalogs and technical brochures

-

MCR-BIII

13 Pages

-

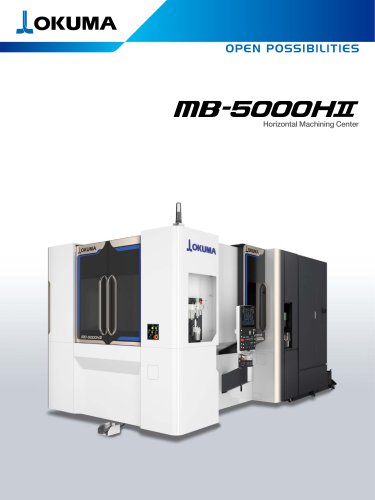

MB-5000HII

11 Pages

-

GENOS M560-V

11 Pages

-

LB2000 EX II

13 Pages

-

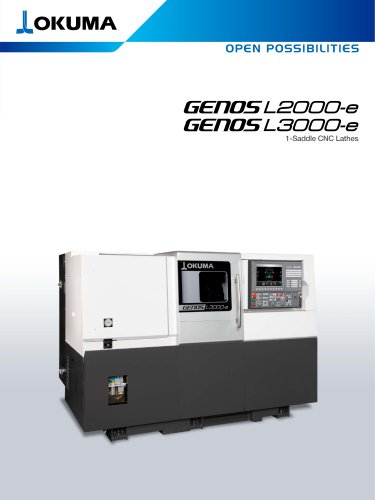

GENOS L2000/L3000-e

13 Pages

Archived catalogs

-

MACHINE TOOLS CATALOGUE

19 Pages

-

MULTUS BII

1 Pages

-

LT-EX Series

1 Pages

-

LU-S Series

1 Pages

-

LU Series

1 Pages

-

LU-EX Series

1 Pages

-

WHEEL MACHINES

1 Pages

-

Double Column

1 Pages

-

vertical_lathes_product_map

1 Pages

-

5_axis_machines_product_map

1 Pages