Catalog excerpts

CONTROX®- Präzisionswerkzeuge CONTROX®- Precision Cutting Tools CATALOG Tools for the Machining of Composite Materials

Open the catalog to page 1

Tools for the machining of composite materials The use of a high precision honeycomb core is machining challenges for those needing to shape growing not only in the aeronautical and space industries, but also in the nautical and automobile industries. The honeycomb industry has developed well developed a wide range of special tools to satisfy beyond the use of meta-aramid honeycombs the tough requirements of honeycomb machining combined with phenolic resin, such as Nomex. There are various metallic and non-metallic composite materials in combination with coatings, adhesive bonding and...

Open the catalog to page 2

PROFILE CUT Shank tools designed for profiling complicated honeycomb parts and structures. The tools are available in centre cutting and ball nose end teeth. Plunge cuts into the honeycomb material are possible. FOAM CUT End Mills especially designed for the machining of technical foams. These cutters have axial and radial teeth. To create smooth radiuses as well as sharp edges on the parts the FOAM CUT tools are in both ball nose and square end available. PANEL CUT Shank tools with end teeth designed for profiling and drilling operations in sandwich panels. Enables extremely high feed...

Open the catalog to page 3

CORECUT Comprehensive and flexible tooling system, mainly for the machining of honeycomb material with 5-axis CNC-machines. Different types of frontend tools and shredders can be combined to suit the demands of your specific application.

Open the catalog to page 5

cannot interfere with the machining process. Without the shredder, the material being removed may wrap around the rotating shaft and damage the material, or even pull the entire work piece off the machine table. For the typical application of CORECUT tools in 5-axis machines, the spindle should be tilted between 1.5° to 3.5° in the feed direction, and another 0.5° to 1.5° sideways (see figure). This way the machining forces point towards the machine table and best results can be achieved. For 3-axis machines where tilting the spindle is not possible, we recommend the POCKET CUT tools....

Open the catalog to page 6

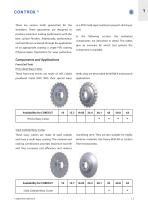

There are various tooth geometries for the shredders. These geometries are designed to produce maximum cutting performance with the best surface finishes. Additionally, performance and tool life are increased through the application of an appropriate coating: a single PVD coating (Physical Vapor Deposition) for wear protection, or a PVD multi-layer coating to prevent sticking as well. In the following section, the individual components are described in detail. The tables give an overview for which tool systems the component is available. Components and Applications Front-End Tools HSS...

Open the catalog to page 7

Circular Knives These front-end knives made of solid carbide have a plain sharp cutting edge. The high quality solid carbide assures a long tool life. For small outer diameters, the knives have a thread and can easily be mounted on the corresponding shank shredder using a screw driver or a coin. Knives with larger outer diameter have an arbor hole and are mounted on to the shredder or shank using the corresponding mounting screw. The circular knives made of solid carbide are available in an uncoated version and with a PVD multi-layer coating. The coating reduces wear to a minimum and...

Open the catalog to page 8

The solid carbide knife with teeth is created to teeth interrupt the cut and prevent a pushing of machine lightweight honeycombs. The special the cell walls in that way. registered trademark

Open the catalog to page 9

Shredders The CORECUT tool family offers a wide range of For small outer diameters (up to CORECUT 25.4) shredder tools. They differ in outer diameter, in the shredders are designed as shank shredders. maximum cutting depth or in tooth geometries. For larger outer diameters (from CORECUT 38.1) They are mounted onto the separately available the shredders have an arbor hole and a similar shank, and thus can easily be exchanged. shape like plain milling cutters. All shredders are made out of HSS cobalt powdered metal (PM). Depending on the application, different tooth geometries are...

Open the catalog to page 10

Some of the plain milling cutter-like shredders (CORECUT 45 and 63) are available in the common short version as well as in a long version. The short version allows for a cutting depth up to approx. 17 mm (0.67"). The long version allows for a cutting depth up to approx. 31 mm (1.22"). According to that, there are also short and long versions of shanks. So please make sure, that you choose the right shank length to match your shredder! short version long version * also available as long version registered trademark

Open the catalog to page 11

Accessories In this section, you will find the shanks for the CORECUT system and the mounting set for the HSS Cobalt saw blades mentioned above. Shanks Controx shanks are made out of HSS and ground a suitable mounting screw and wrench. All parts to h6 tolerance to fit shrinking chucks. All shanks are deliverable as spare parts as well. are available in sets, each containing a shank, There are shanks in various diameters – metric with a cutting depth up to approx. 17 mm (0.67“; and imperial. For CORECUT 45 and CORECUT 63 short version). The long versions are suitable for short and long...

Open the catalog to page 12

short version The shanks for CORECUT 38.1 and CORECUT 45 Also the shanks CORECUT 50.8 und CORECUT 63 (short version) are identical and thus may be used (short version) are identical. with shredders and front-end tools of either size. Mounting Set for HSSCo Saw Blade This mounting set is necessary for the usage of the above mentioned HSS Cobalt saw blades of the CORECUT system and assures accurate fitting. It consists of a centering washer (to assure centered position of the saw), a spring washer (to clamp the saw blade in hollow position), a screw and corresponding wrench. The...

Open the catalog to page 13

Technical Specifications

Open the catalog to page 15

Front-End Tools SC=Solid Carbide PM=HSSCo Powdered Metal registered trademark

Open the catalog to page 16

Front-End Tools SC=Solid Carbide PM=HSSCo Powdered Metal registered trademark

Open the catalog to page 17All NEUHÄUSER PRÄZISIONSWERKZEUGE GMBH catalogs and technical brochures

-

CATALOGUE

84 Pages

-

PANEL CUT / DECORING CUT

4 Pages

-

FIBER CUT

4 Pages