Catalog excerpts

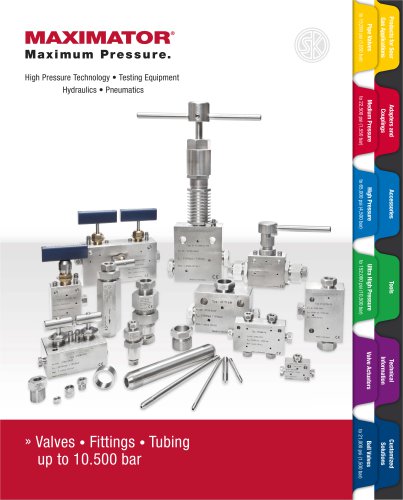

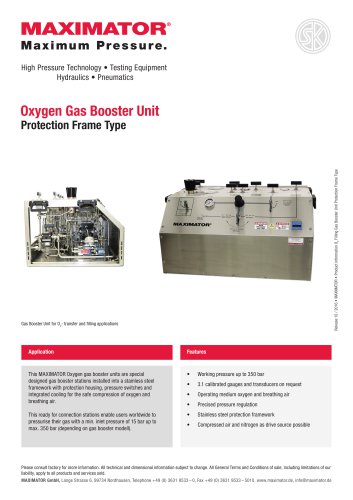

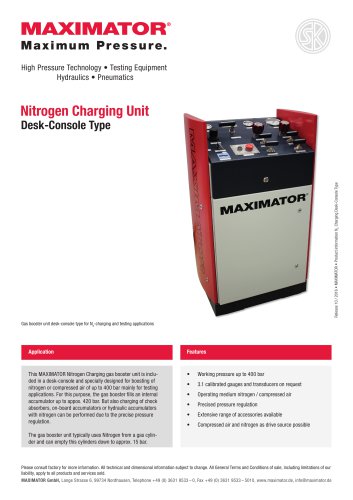

Pipe Valves Products for Sour Gas Applications to 22,500 psi (1,550 bar) Medium Pressure High Pressure Ultra High Pressure Tools Valve Actuators Technical Information Ball Valves Customized Solutions » Valves • Fittings • Tubing up to 10.500 bar High Pressure Technology • Testing Equipment Hydraulics • Pneu

Open the catalog to page 1

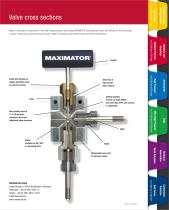

Pipe Valves Products for Sour Gas Applications Medium Pressure High Pressure Ultra High Pressure Valve Actuators Technical Information Ball Valves Customized Solutions Valve cross sections Based on decades of experience in the field of high pressure technology MAXIMATOR manufactures valves and fittings for the oil and gas industry, chemical and petrochemical industry, water-jet cutting, power systems and test bench manufacture. Gland with packing of copper aluminium alloy for smooth running Slide disc of high-tensile slide material Sealing packing of back-up rings (PEEK) and seal rings (PTFE...

Open the catalog to page 2

State-of-the-art technical know-how based on German engineering, successful system developer and experienced specialist - MAXIMATOR GmbH is a leading supplier of high pressure and testing technology, hydraulic and pneumatic equipments. Qualified and motivated company members are developing, designing, manufacturing and marketing products internationally which are worldwide employed in process technology plants. At its headquarter in Nordhausen MAXIMATOR GmbH develops, designs and manufactures high pressure equipment. In our purposefully-built development and service centre in Nordhausen...

Open the catalog to page 3

Pipe Valves Products for Sour Gas Applications Medium Pressure High Pressure Ultra High Pressure Valve Actuators Technical Information Ball Valves Customized Solutions Valves, Fittings and Tubing MAXIMATOR has been designing and manufactaring high pressure equipment for more than thirty years and has a worldwide reputation for quality and reliability, backed by one of the best service organizations in the industry. Pipe Valves and Fittings to 15,200 psi (1,050 bar) MAXIMATOR offers a complete line of pipe fittings, pipe hex nipples, pipe check valves and pipe line filters. All pipe valves use...

Open the catalog to page 4

Pipe Valves and Fittings Components Pressures to 15,200 psi (1,050 bar) Pipe Valves, Pipe Fittings, Pipe Hex Nipples, Pipe Check Valves, Pipe Line Filters Valves, Fittings, Anti-Vibration Collet Gland Assemblies, Tubing, Coned and Threaded Nipples, Check Valves, Line Filters, Angle Filters, Safety Head Assemblies, Rupture Discs Valves, Fittings, Anti-Vibration Collet Gland Assemblies, Tubing, Coned and Threaded Nipples, Check Valves, Line Filters, Angle Filters, Safety Head Assemblies, Rupture Discs Valves, Fittings, Tubing, Coned and Threaded Nipples Air to Close (normally open), Air to...

Open the catalog to page 5

Pressure Component Type Orifice Diameter Connection “A” (only required on ball valves) Size Type 15 = 15,200 psi (1,050 bar) A = Adapter (male / female) 3 = 3/16“ diameter 2 = 1/8” B = BSP Pipe 21 = 22,500 psi (1,550 bar) AF = Angle Filter 4 = 1/4“ diameter 4 = 1/4” P = NPT Pipe 22 = 22,500 psi (1,550 bar) AVA = Anti-Vibration Collet Gland Assembly 6 = 3/8“ diameter 5 = 5/16” M = Medium Pressure 30 = 30,000 psi (2,070 bar) B2 = 2-Way Ball Valve 8 = 1/2“ diameter 6 = 3/8” H = High Pressure 36 = 36,000 psi (2,500 bar) B3D = 3-Way Diverter Ball Valve (90°) 8 = 1/2” U = Ultra High Pressure 43 =...

Open the catalog to page 6

Stem Type (only required on needle valves) Body Pattern (only required on needle valves) Connection “B” Size Type Options CD 00 = Vee Stem one piece rotating 1 = Two-way straight 01 = Regulating Stem one piece rotating 2 = Two-way angle 07 = Vee Stem non rotating 3 = Three-way, two on pressure 08 = Regulating Stem non rotating 4 = Three-way, one on pressure 80 = Vee Stem one piece rotating / 5 = Three-way, two stem manifold replaceable seat 81 = Regulating Stem one piece rotating / replaceable seat 87 = Vee Stem with replaceable seat non 88 = Regulating Stem w / replaceable If different...

Open the catalog to page 7

Pipe Valves Products for Sour Gas Applications Medium Pressure High Pressure Ultra High Pressure Valve Actuators Technical Information Ball Valves Customized Solutions Pipe Valves, Fittings and Nipples MAXIMATOR has been designing and manufacturing high pressure equipment for more than thirty years and has a worldwide reputation for quality and reliability, backed by one of the best service organizations in the industry. Pipe Valves, Fittings and Nipple feature: • Rising stem design. • 316 L (1.4404) wetted parts and 17-4 PH Stem for excellent corrosion resistance. • Metal-to-metal seating...

Open the catalog to page 8

Ordering Information Typical catalog number: 15V4B071 Pipe valves Maximator Pipe valves with metal to metal seats have a high level of safety and reliability under adverse operating conditions. These valves may be used both with gases and liquids. Traceability is ensured through extensively documented data (batch number, maximum pressure, material number, type designation). Valve Series Thread Size Stem Type 4P - 1/4” NPT 08 - non-rotating REGULATING stem* Body Pattern Options for Pipe Valves Special Designs for Extreme Temperatures Standard valves are supplied with Teflon / Carbon packing...

Open the catalog to page 9

G - Panel mounting screw thread size 10-24 UNC (screw included). All dimensions are for reference only and are subject to change. All technical and dimensional information subject to change. All general Terms and Conditions of sale, including limitations of our liability, apply to all products and services sold. 3999.1946 | 09/2019 Customized Solutions Technical Information Products for Sour Gas Applications Ball Valves Valve Actuators Ultra High Pressure High Pressure Medium Pressure Valve Block Panel ThickHole ness Pipe Valves Stem Type Catalog Number Valve Pattern

Open the catalog to page 10

Maximator Pipe Fittings are designed for liquid and gas applications. The P Series Fittings are available from 1/4” to 1”NPT to 15,200 psi (1,050 bar). NPT threads must be sealed using a high quality PTFE tape and/or paste product. Sealing performance may vary based on many factors such as pressure, temperature, media, thread quality, thread material, proper thread engagement and proper use of thread sealant. MAXIMATOR recommends to limit the number of times an NPT fitting is assembled and disassembled because thread deformation during assembly will result in deteriorating seal quality over...

Open the catalog to page 11All Maximator GmbH catalogs and technical brochures

-

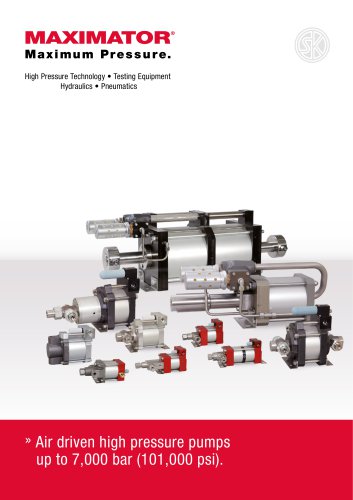

Gas Booster and Air Amplifier

56 Pages

-

LGP-Series

16 Pages

-

High-Pressure-Pumps

40 Pages

-

Maximator Image brochure

24 Pages

Archived catalogs

-

Maximator-Rental-Units

28 Pages

-

MAXIMATOR Gas Seals

4 Pages

-

Maximator Proportional Valve

7 Pages

-

MX-Compressors

24 Pages

-

Oil and Gas Technology

24 Pages

-

MAXIMATOR Valves Fittings Tubing

168 Pages

-

MAXIMATOR Gas Boosters

32 Pages

-

Air Amplifier Stations

12 Pages