Catalog excerpts

MAXI MATO R Maximum Pressure. High Pressure Technology • Testing Equipment Hydraulics • Pneumatics How do we stretch the boundaries of oil and gas production? With high pressure equipment and pressure systems up to 25,000 bar

Open the catalog to page 1

Maximum safety for oil and gas production As a specialist for high-pressure technology for up to 25,000 bar, we make the extraction of crude oil and natural gas efficient and safe – with high-performance products and high-pressure systems for testing and production purpose in surface and subsea applications. Contents : Maximum safety for oil and gas production 2 – 3 Valves, Fittings and Tubing up to 10,500 bar 4 – 5 High pressure units and components for fluids 6 – 7 High pressure units and components for gas 8 – 9 Supply systems for mechanical seals High pressure workshop testing equipment...

Open the catalog to page 2

In every phase, your projects profit from our specific engineering expertise - from the quotation phase, to the delivery – including engineering phase. • Project management: Our workflows achieve prompt results due to efficient and organized work processes. • Services, research and development: To ensure everything matches your project, we carry out tests and modifications in line with your guidelines for your products and systems, be they standard or customized developments, flexibly on our own high-pressure testing systems in our service centers. We can fall back on more than 70...

Open the catalog to page 3

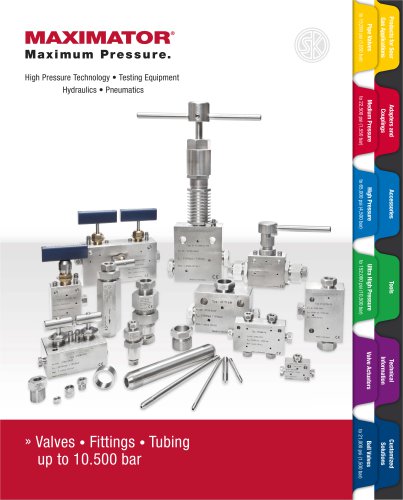

How is the rigging of oil and gas production plants made a surefire thing? » With valves, fittings and tubing up to 10,500 bar. Reliable and high-quality components made of high-strength materials are essential elements of the equipment for high-pressure applications. Valves, fittings and tubing from Maximator for onshore and offshore production projects are designed for productivity and secure system operation. Components from the manufacturer – for all requirements As a system manufacturer of testing and production systems for high pressures up to 25,000 bar, we concentrate on quality and...

Open the catalog to page 4

Valves, fittings and tubing up to 10,500 bar (152,000 psi): • Needle valves, fittings and pipes (1/4– 1“) • 2-way and 3-way ball valves (1/4– 9/16“) • Anti-vibration collet gland assemblies, filters and check valves • Pneumatic and hydraulic actuated high pressure needle valves • Adapters and couplings (NPT, BSPP, JIC, etc.) • Test and Product Certification (GOST, 3.1, etc.) Special products • Special valves made to specifications • Special material available (Duplex, Super Duplex, Inconel, Hastelloy, etc.) • Special configuration (needle, ball and needle, shut-off and relief valves (1x and...

Open the catalog to page 5

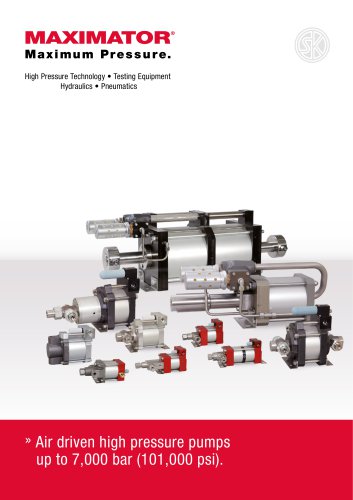

How do you keep your hydraulics safe at high pressure levels? » With high pressure units and components for fluids. High-pressure pumps and systems from Maximator allow reliable testing of pressurised hydraulic equipment and components in oil and gas drilling and production operations. The compact units and systems also assume functions such as the calibration of pressure measuring instruments, the supply of pressure to hydraulic control systems for well equipment or chemical injection. Safe under extreme conditions: Maximator high-pressure pumps Our high-pressure pumps generate hydraulic...

Open the catalog to page 6

Pumps - performance and features: • 17 different construction series for pressure levels up to 7,000 bar and flow capacities up to 48 l/min • Compressed air drive allows operation in explosive areas • Alternative drive media possible • Optionally, also suitable for use with media containing H2S • Standstill when the set final pressure is reached without energy consumption Power Packs - safe grades: • Only high-quality materials are used for maximum resistance • No electrical connection required for operation • Control panels with logical design ensure safe operation • Compact design with...

Open the catalog to page 7

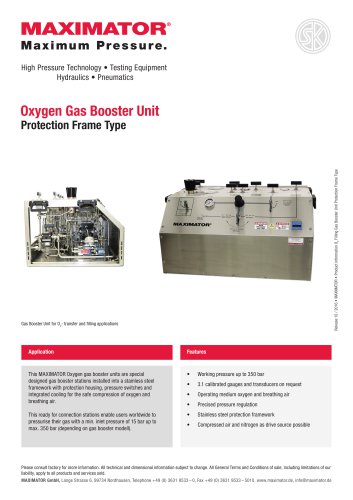

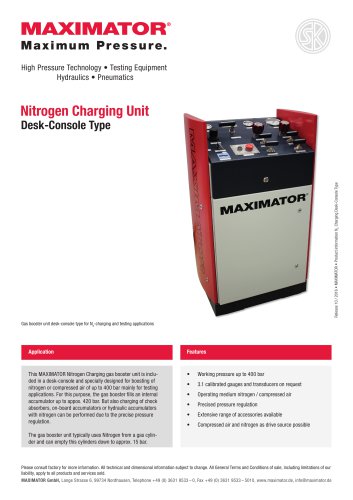

How do you hit high gas pressure levels safely on drilling platforms? » With high pressure units and components for gas. Imperative for the oil and gas production, often a challenge in practice: compressing technical gases. Maximator high-pressure gas boosters and booster stations set the fluids exactly to the process requirements and generate high gas pressure levels up to 2,400 bar reliably - directly on site. Smart from the drive to the cooling Our oscillating gas boosters of the DLE series compress technical gases and gas mixtures up to 2,400 bar, hydrogen up to 1,000 bar and oxygen up...

Open the catalog to page 8

High-pressure booster of the DLE series – performance range: • Compressed air driven booster for compressing technical gases such as argon, helium, oxygen, hydrogen and nitrogen up to 2,400 bar • Effective gas compression thanks to broad-based product range (single-acting, double-acting and 2-stage booster) • High level of safety thanks to the physical separation of the drive and process gas and also additional connections for flushing the booster with inert gases for applications with critical media Booster stations - equipment • Control panels with logical design ensure safe operation •...

Open the catalog to page 9

How do turbo compressors supply your gas in a safe process? » With supply systems for mechanical seals. Gas or liquid sealed: mechanical seals keep pumped media safely in the system for numerous processes in the oil and gas production sector. Supply units guarantee that the dynamic seals function to the optimum under tough conditions by cooling, flushing, applying pressure and compensating leaks – on drill platforms and on FPSO ships, as well as in subsea production systems. Protect the production process Maximator supply systems offer specific solutions for mechanical seals in crude oil,...

Open the catalog to page 10

Maximator solutions for liquid sealed mechanical seals: • Central feed-in units for several mechanical seals in compliance with API 53b, Atex-conform with redundant pressure generation • Air and water cooler in compliance with API 53b with a high cooling output thanks to laser-welded ribbed tubing with low flow resistance • External circulation system acc. to API 54 • Thermosyphon vessels, nitrogen booster stations and emergency supply systems in compliance with API 53a Maximator solutions for gas sealed mechanical seals: • Booster stations for increasing the pressure in compliance with API...

Open the catalog to page 11All Maximator GmbH catalogs and technical brochures

-

Gas Booster and Air Amplifier

56 Pages

-

Valves-Fittings-and-Tubings

175 Pages

-

LGP-Series

16 Pages

-

High-Pressure-Pumps

40 Pages

-

Maximator Image brochure

24 Pages

Archived catalogs

-

Maximator-Rental-Units

28 Pages

-

MAXIMATOR Gas Seals

4 Pages

-

Maximator Proportional Valve

7 Pages

-

MX-Compressors

24 Pages

-

MAXIMATOR Valves Fittings Tubing

168 Pages

-

MAXIMATOR Gas Boosters

32 Pages

-

Air Amplifier Stations

12 Pages