Catalog excerpts

M a x i m u m P r e s s u r e. High Pressure Technology • Testing Equipment Hydraulics • Pneumatics How do we push the realms of possibility? » With testing and production systems up to 20,000 ba

Open the catalog to page 1

High pressure with system. Whether it’s automobiles, commercial vehicles, heavy duty diesels or in aviation Maximator sets global standards in the high-tech industry with its testing and production technology. High pressure with system Pressure fatigue technology Leak testing technology Plastic components Hydrogen applications Your partner for high-pressure and testing technology MAXIMATOR GmbH successfully develops complex systems in highpressure and testing technology, hydraulics and pneumatics and has been the market leader in these segments for decades. As a specialist in high pressure...

Open the catalog to page 2

In order to solve your testing challenges optimally and efficiently, we guide you with our engineering know-how from preparation of the machine specifications through to commissioning and staff training. • Analysis and feasibility studies: We analyse your product and the test requirements in detail. • Research and development: We develop customised solutions for pressure generation and to adapt your test specimens. Our testing centres guarantee the highest, constant quality. More than 70 engineers, technicians and programmers support us for maximum professionalism. • Production: More than...

Open the catalog to page 3

How do you prevent a 2 kilogram injector from bringing 500,000 tons to a standstill? » With autofrettage. Autofrettage is a manufacturing process for highly pressurised components. Industry branches such as shipping, aviation or heavy vehicle constructions use the innovative technology to significantly increase the service life of high pressure components and therefore reduce costs. Effect of the technology Components made of ductile steel are given fatigue strength with autofrettage without needing structural or material customisations. Workpieces are subjected to high pressure of up to...

Open the catalog to page 4

Maximator systems can autofrettage: • Diesel injection technology components (common rails, injection nozzles, pump housings, injection nozzle holders and diesel lines) • High pressure technology components (pipes, fittings, components and high pressure pumps etc.) • Inner high pressure moulding components • Water jet technology components Application areas in the process • Autofrettage system for prototypes - in development or sampling for research and development, individual component autofrettage and small batches • System for series products - in production Performance features: • Short...

Open the catalog to page 5

How can you predict the fatigue life of critical engine components? » With pressure fatigue testing technology. With the pressure fatigue testing conducted on MAXIMATOR’s highly engineered impulse test benches the fatigue strength of materials and components is established under realistic conditions. In the automobile industry and in mechanical engineering, they allow the initial and calculation concepts (FEA and simulation) to be reviewed to optimise the construction and design of components in diesel injection technology and to validate it. Effect of the technology Pressure fatigue test...

Open the catalog to page 6

Maximator systems test: • Diesel injection technology components (rails, injection nozzles, pump housings, injection nozzle holders and lines) • High pressure technology components (pipes and fittings etc. • Pressure sensors • Pressurised components for industrial applications (e.g. on hydraulic quick clamp jaws for processing centres) Performance features: • High system availability • Very high control accuracy • Test statistics based on normal distribution • Fully programmable sinus, trapezoid and triangle curves • Pulse pressure up to 6,000 bar • Energy-efficient system design •...

Open the catalog to page 7

How do you ensure your leak-tight parts are truly sealed? » With leak testing technology. Pressure and leak tests are efficient methods for analysing the functional and tightness properties of pressurized components. Manufacturers in the automobile industry, mechanical engineering and chemical industry determine product and component characteristics with this method. Effect of the technology A basic requirement for the function of many technical components is their tightness. With professional leak tests, hoses, pipes, containers, cooling and air-conditioning systems, fuel and injection...

Open the catalog to page 8

Maximator systems test: • Pressurised components • High pressure technology components (pipes and fittings etc.) • Hoses • Diesel injection components Test methods • Verification procedure with test gas (H2, SF6, N2O, N2) • Verification using pressure drop measurement • Leak test with pressure compensation and gas volume measurement Performance features: • Short setup times • Short cycle times • High system availability • Automated test processes

Open the catalog to page 9

How can cars be more fuel efficient? » With high pressure tests on plastic components. At MAXIMATOR qualified test procedures for plastic components pave the way for safe basis innovations in vehicle construction. Special test systems make load tests on these components possible in running production operations, which allow the vehicle weight to be reduced and contribute to savings in fuel. Effect of the technology Tests on plastic components provide information on whether the components fulfil the planned functions. Different testing methods such as burst pressure testing, leak tests and...

Open the catalog to page 10

Maximator systems test • pressurised plastic components in the automotive field: - Cooling water system - Pressure compensation tank - Suction module - Pipes and lines in the motor - Filter housing Performance features • Customised concepts • Tests according to DIN norms or specific customer requirements • Pressure load change test with different liquids/gases • Modular setup with temperature chamber (up to 300°C) or climate chamber (-40°C - +180°C) • Safety: test chambers integrated in closed ..containers" • Backfire tests • Flow measurements • Pressure fatigue tests • Burst pressure...

Open the catalog to page 11All Maximator GmbH catalogs and technical brochures

-

Gas Booster and Air Amplifier

56 Pages

-

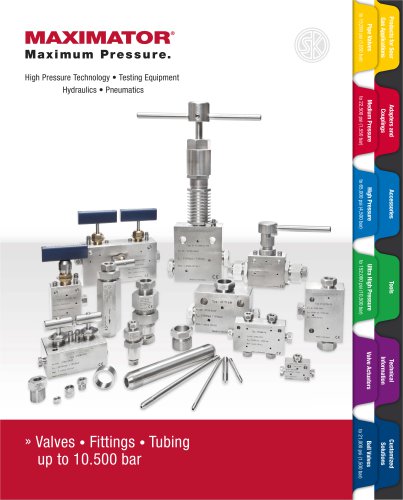

Valves-Fittings-and-Tubings

175 Pages

-

LGP-Series

16 Pages

-

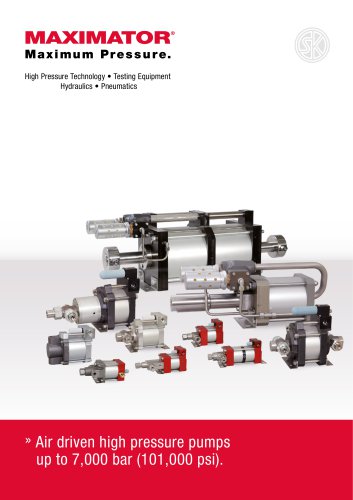

High-Pressure-Pumps

40 Pages

-

Maximator Image brochure

24 Pages

Archived catalogs

-

Maximator-Rental-Units

28 Pages

-

MAXIMATOR Gas Seals

4 Pages

-

Maximator Proportional Valve

7 Pages

-

MX-Compressors

24 Pages

-

Oil and Gas Technology

24 Pages

-

MAXIMATOR Valves Fittings Tubing

168 Pages

-

MAXIMATOR Gas Boosters

32 Pages

-

Air Amplifier Stations

12 Pages