Catalog excerpts

HIGH PRESSURE TECHNOLOGY HYDRAULICS PNEUMATICS TESTING EQUIPMENT critical point triple point

Open the catalog to page 1

Index Company portrait 3 Test benches and gas assist systems 5 After-sales-service and research systems 6 Model overview and type coding 10 Technical features of the MAXIMATOR Gas booster line 31

Open the catalog to page 2

MAXIMATOR is one of the worldwide leading manufacturers of air driven liquid pumps, air amplifiers, gas boosters, high pressure valves, fittings and tubing as well as associated products like pressure switches and further components for applications in high pressure technology. All our systems and units comply with the applicable UVV [accident prevention] regulations, the European Machine, Pressure Equipment and ATEX Directives and, upon request, also conform to NACE specifications. Our strict quality guidelines are certified to ISO 9001. To ensure the continuation of future developments we...

Open the catalog to page 3

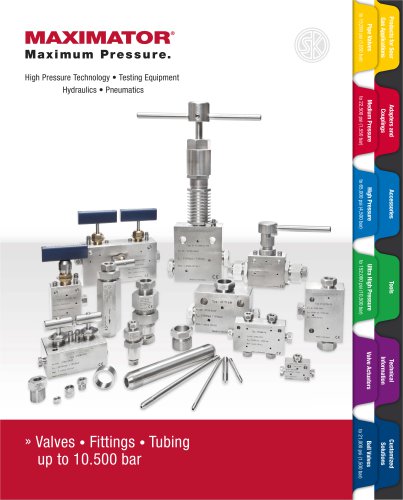

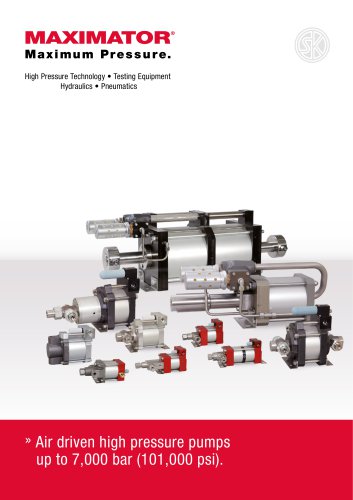

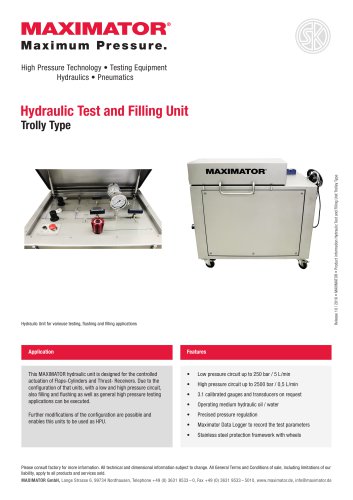

1 Pressure intensification of liquids and gases Packaged pump systems for oil, water and other liquids for the following applications: 1 Tool hydraulics 1 Clamping hydraulics 1 Water hydraulics Air driven liquid pumps Operating pressures to 5,500 bar (79,750 psi) Air amplifiers 1 Operating pressures to 40 bar (580 psi) 1 Selective amplification of shop air Test benches and pressure generating systems Valves, fittings, tubing for high pressure technology 1 Stainless steel design in high manufacturing quality 1 Temperature range from –250°C (-418°F) to +650°C (1,202°F) for liquids and gases 1...

Open the catalog to page 4

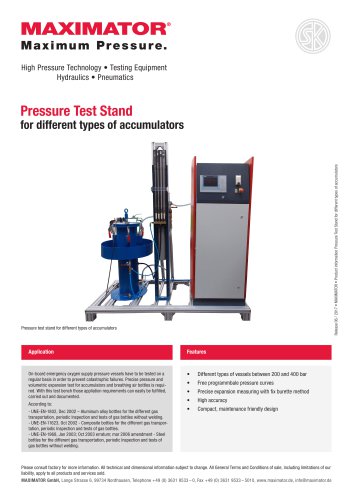

Test benches and gas assist systems Compressors, testing and regulating systems 1 Centralised supply for gas assist systems 1 Testing and regulating systems for shop air and gases 1 Complete systems to fill air bag gas cartridges We are in a position to test your product for you in the following fields: This special method is used in plastics injections moulding and provides the following advantages 1 Constructional design recommendations 1 Scientific development …Serial production 1 Material savings of up to 50% 1 Reduction of locking pressures 1 Avoidance of sink marks 1 Production...

Open the catalog to page 5

On- and Offshore Solutions Specifically for the Oil and Gas industry we have developed a range of standard units which are suitable for these applications. Available options The units are protected against mechanical and environmental damage by using a stainless steel frame which also helps with transportation of the unit. The control and operation elements are ergonomically mounted into a control panel. 1 Stroke counter 1 Chart recorder Please ask for our brochure „On and Offshore Solutions“. Complete solutions for high pressure technology Design and development, manufacturing,...

Open the catalog to page 6

Scope of applications The MAXIMATOR high pressure boosters are suitable for the oil free compression of gases and air. Industrial gases like Argon, Helium, Hydrogen and Nitrogen can be compressed to operating pressures of 1,500 bar (21,750 psi), Oxygen to 350 bar (5,075 psi). Air driven boosters are an efficient alternative instead of electrically driven products and can be used in explosion-proof areas . As a result of the wide range of models it is possible to select the optimum booster for each application. Single stage, double acting or two stage boosters or a combination of these...

Open the catalog to page 7

Application examples Cleaning of burner systems Airbag systems Cylinder charging Blowing out contaminations through pressure blasting at 16 bar (232 psi) Charging of airbag systems with Helium to 800 bar (11,600 psi) Use remaining pressure for recharging Pressure test PC evaluation Actual value evaluation Operating panel Inlet N2 Analog measuring value display Booster 2 Sample Set value Test chamber Leak test with high gas pressure 8

Open the catalog to page 8

Application examples Life-guard service Transfer of oxygen in small cylinders Colour changing systems Piggeable ball Colour system Colour Blue Colour Yellow The colour will be returned into the tank through a piggeable ball which is charged with pressure Plastic industry Compression of gas and regulation for the gas assisted injection moulding Precharging of hydraulic accumulators by nitrogen 9

Open the catalog to page 9

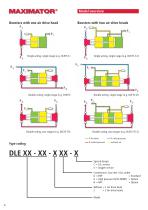

Model overview Boosters with one air drive head Boosters with two air drive heads Single acting, single stage (e.g. DLE15-1) Single acting, single stage (e.g. DLE15-1-2) Double acting, single stage (e.g. DLE15) Double acting, single stage (e.g. DLE15-2)) Double acting, two stages (e.g. DLE15-75) Double acting, two stages (e.g. DLE15-75-2) PL Air drive Type coding DLE XX - XX - X XX - X Special design C = CO2 service S = Oxygen service Connections: Gas inlet / Gas outlet G = BSP = Standard U = High pressure (9/16-18UNF) = Option N = NPT = Option Without = 1 Air drive head 2 = 2 Air drive...

Open the catalog to page 10

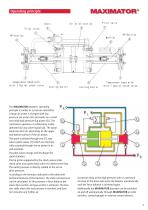

Operating principle The MAXIMATOR boosters’ operating principle is similar to a pressure intensifier. A large air piston is charged with low pressure (air piston (3)) and works on a small area with high pressure (hp piston (2)). The continuous operation is achieved by a pilot operated 4/2 way valve (spool (4)). The spool leads the drive air alternately on the upper and bottom surface of the air piston. The spool is piloted through two 2/2 way valves (pilot valves (7)) which are mechanically actuated through the air piston in its end positions. The pilot valves charge and discharge the spool...

Open the catalog to page 11

Model: DLE2-1 Flow: 150 Umin (5.3 SCFM) at inlet pressure of 3 bar (43 psi), outlet pressure of 6 bar (87 psi) and air drive pressure of 6 bar (87 psi) Flow: 190 Umin (6.7 SCFM) at an inlet pressure of 3 bar (43 psi), outlet pressure of 10 bar (145 psi) and air drive pressure of 6 bar (87 psi) • small dimension • price attractive solution Technical features DLE 2-1 Technical features DLE 2

Open the catalog to page 12

Flow: 160 Umin (5.65 SCFM) at inlet pressure of 3 bar (43psi) outlet pressure of 10 bar (145 psi) and air drive pressure of 6 bar (87 psi) Flow: 190 Umin (6.7 SCFM) at an inlet pressure of 3 bar (43 psi), outlet pressure of 16 bar (232 psi) and air drive pressure of 6 bar (87 psi) • small dimension • high outlet pressure • high outlet pressure • less pulsation Technical features

Open the catalog to page 13All Maximator GmbH catalogs and technical brochures

-

Gas Booster and Air Amplifier

56 Pages

-

Valves-Fittings-and-Tubings

175 Pages

-

LGP-Series

16 Pages

-

High-Pressure-Pumps

40 Pages

-

Maximator Image brochure

24 Pages

Archived catalogs

-

Maximator-Rental-Units

28 Pages

-

MAXIMATOR Gas Seals

4 Pages

-

Maximator Proportional Valve

7 Pages

-

MX-Compressors

24 Pages

-

Oil and Gas Technology

24 Pages

-

MAXIMATOR Valves Fittings Tubing

168 Pages

-

Air Amplifier Stations

12 Pages