Website:

KOYO BEARINGS VIERZON MAROMME (GROUPE JTEKT)

Website:

KOYO BEARINGS VIERZON MAROMME (GROUPE JTEKT)

Group: JTEKT Group

Catalog excerpts

OIL SEALS & O-RINGS OIL SEALS & O-RINGS

Open the catalog to page 1

OIL SEALS fi O-RINGS ■ Koyo Oil Seals: Features ■ Koyo O-Rings: Features ■ Koyo Functional Products: Features ■ FEM (Finite Element Method) Analysis 1. Oil Seals Engineering Section Dimensional Tables 2. O-Rings Engineering Section Dimensional Tables Engineering Data 5. Request Forms for Oil Seal Design and Production

Open the catalog to page 2

JTEKT CORPORATION KOYO SEALING TECHNO CO., LTD.

Open the catalog to page 3

Preface This catalog lists Koyo oil seals and O-rings, including all items of the dimension series specified in ISO, JIS and JASO (Japanese Automobile Standards Organization) standards. This catalog is also based on knowledge gained from our supply record, experience, expertise, technologies, and research developments that JTEKT and KOYO SEALING TECHNO have acquired in cooperation with customers since its foundation in 1964. A specialty of this new catalog is the comprehensive information, it offers regarding the selection and handling of oil seals and O-rings. Energy-saving, efforts to...

Open the catalog to page 4

3. Application Examples of Oil Seals and O-Rings 3.1 3.2 3.3 3.4 3.5 3.6 5. Request Forms for Oil Seal Design and Production

Open the catalog to page 5

■ Koyo Oil Seals: Features 1. Lightweight, compact, and energy-saving Koyo oil seals offer high sealing performance, while being compact with reduced seal width. They help reduction of machine weight, size, and resource consumption 2. High sealing performance by optimum lip design Koyo oil seals employ a linear-contact lip, which provides proper radial lip load. The lip design ensures excellent sealing performance, low torque, proper flexibility and high allowability for eccentricity. 3. Low heat generation and long service life by highly self-lubricating rubber materials Based on extensive...

Open the catalog to page 6

■ Koyo O-Rings: Features 1. High sealing performance and reliability High sealing performance against water, oil, air, various gases and chemicals. 2. Available in a full lineup of designs and sizes 3. Easy handling

Open the catalog to page 7

■ Koyo Functional Products: Features JTEKT produces various functional products based on advanced sealing technologies and sophisticated manufacturing expertise acquired through extensive research and development. Koyo functional products are very helpful in improving machine performance, reducing weight, size, noise and vibration. Consult JTEKT if there is no product in this catalog that exactly matches your requirements--JTEKT can custom-design products. 1. Functional products for automobiles and industrial machinery • Center bearing unit • Bearings molded with vibration isolating rubber...

Open the catalog to page 8

2. Functional products for motorcycles • Air cleaner joint • Carburetor joint • Muffler joints • Plastic gear shafts • Oil strainer • Mesh gasket • Ball-component clutch releases • Vertical gaskets • Chain tensioner • Chain guide

Open the catalog to page 9

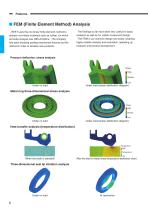

■ FEM (Finite Element Method) Analysis JTEKT uses the non-linear finite element method to analyze non-linear materials such as rubber, for which accurate analysis was difficult before. The company has been studying sealing-mechanism theories by this method in order to develop new products. The findings so far have been very useful for basic research as well as for rubber-component design. The FEM is our common design tool today, enabling highly reliable analysis and evaluation, speeding up research and product development. Pressure deflection, stress analysis Stress High Tension Low Under...

Open the catalog to page 10

1.1 Nomenclature and functions of seal components 1.1 Nomenclature and functions of seal components (1) Nomenclature of components Oil seals are designed in a variety of shapes according to the applications and substances to be sealed. Fig. 1.1.1 shows a typical shape of seal and its component nomenclature. Oil seals work to prevent leakage of sealed objects such as lubricants from inside and also to prevent the entry of dust and contaminants from outside. 5 Metal case 6 O.D surface 7 Fluid side face Sealed side Fig. 1.1.1 Typically shaped oil seal and component nomenclature (2) Component...

Open the catalog to page 12

Because this spring is a closely wound type coil, the initial tension can be obtained high level, and then changes in load characteristics can be gradual with respect to spring elongation. Tension at the sealing edge can thus be kept stable at an appropriate level. Spring rate (slope of line) Spring load The spring supplements the tension at the sealing edge to ensure tight contact between the shaft and the sealing edge and enhanced sealing performance. The spring also prevents the deterioration of main lip sealing performance caused by high heat or others. Inflection point Initial tension...

Open the catalog to page 13

1.2 Seal numbering system 1.2 Seal numbering system Table 1.2.1 Seal numbering system MH: O.D wall is rubber material HM: O.D wall is metal case HM(S)H: O.D wall is metal with a reinforcing inner metal case. (A spring is always provided for this type.) Remark) For the type codes of special type seals, refer to Section 1.3. ■ Koyo oil seals: Features Rubber O.D wall prevents leakage efficiently under pressure Nose gasket prevents leakage through the seal O.D Light metal case with sufficient rigidity Lip design with excellent followability Linear contact type sealing edge with high durability...

Open the catalog to page 14

Table 1.3.2 lists the seal type codes used at JTEKT, along with the corresponding codes used in the ISO, JIS, and JASO standards. 1.3 Seal types (1) Common seal types and their features Seals are classified by O.D wall material, lip type and whether with spring or without spring. Major oil seals are specified in ISO 6194 and JIS B 2402. Table 1.3.1 shows common seal types. Table 1.3.1 Oil seals of common types With spring Without spring Metal O.D wall with a reinforcing ^3) 4) inner metal case Rubber O.D wall Without minor lip Type code MHS Type code Features of each type 1) With spring...

Open the catalog to page 15

1.3 Seal types (2) Special seal types and their features JTEKT and Koyo sealing techno Co.,Ltd. provide special seals to meet a wide variety of machines and applications: Table 1.3.3 Oil seals of special types (1) : For bi-directional rotation Seal type Type code and shape Perfect Seals The hydrodynamic ribs provided in two Reduction gears input directions on the air side face of the lip shafts ensure improved pumping effect and Differential gear sides higher sealing performance in both rotational directions of the shaft. Helix Seals MHSA...XRT MHSA...XLT MHSA...XRT MHSA...XLT Double Lip...

Open the catalog to page 16All KOYO BEARINGS VIERZON MAROMME (GROUPE JTEKT) catalogs and technical brochures

-

Standard Bearings

241 Pages

-

Ball & Roller Bearing

84 Pages

-

TAPERED ROLLER BEARINGS

107 Pages

-

Needle Roller Bearings

274 Pages

-

LARGE SIZE BALL & ROLLER BEARINGS

247 Pages

Archived catalogs

-

Wind Turbine Generators

4 Pages

-

High Wing Series Drive Shafts

30 Pages

-

B2004E Ceramic & EXSEV

71 Pages

-

B1021E Slim Bearing

2 Pages

-

B1013E Ceramic Bearings

17 Pages

-

B1011E Traction Drive Unit

4 Pages

-

B1005E EXSEV Product Guidebook

13 Pages

-

Agriculture and Construction

6 Pages