Website:

KOYO BEARINGS VIERZON MAROMME (GROUPE JTEKT)

Website:

KOYO BEARINGS VIERZON MAROMME (GROUPE JTEKT)

Group: JTEKT Group

Catalog excerpts

BEARINGS AND CERAMIC BEARINGS BEARINGS AND CERAMIC BEARINGS FOR EXTREME SPECIAL ENVIRONMENTS EXSEV BEARINGS AND CERAMIC BEARINGS FOR EXTREME SPECIAL ENVIRONMENTS EXTREME SPECIAL ENVIRONMENTS

Open the catalog to page 1

BEARINGS AND CERAMIC BEARINGS FOR EXTREME SPECIAL ENVIRONMENTS ✩ The contents of this catalogue are subject to change without prior notice. We took special care in preparing the contents of this catalogue. JTEKT does not accept liability for errors, omissions, or missing pages, or any loss incurred from the use of this catalogue. Reproduction of this catalogue or any part there of without JTEKT's prior permission is strictly prohibited.

Open the catalog to page 2

Products and Applications Development and Manufacturing Facilities 1 BEARINGS AND CERAMIC BEARINGS FOR EXTREME SPECIAL ENVIRONMENTS Bearings: Composition and Selection 1 Ceramic Bearings and Special Steel Bearings ………………………………………… 3 2 Lubricants for EXSEV Bearings …………………………………………………………………… 11 3 How to Select EXSEV Bearings …………………………………………………………………… 14 4 EXSEV Bearings with Special Characteristics ………………………………………… 19 1 EXSEV Bearings and Ceramic Bearings: Table of Specifications …… 25 2 EXSEV Bearings and Ceramic Bearings: Table of Characteristics … 27 3 Radial Ball Bearings...

Open the catalog to page 3

• Clean Pro PRZ Bearings • High Temperature Clean Pro Bearings • Clean Pro Bearings 9 DL Bearings • FA Bearings • High Corrosion Resistant Ceramic Bearings • Corrosion Resistant Ceramic Bearings • Ceramic Bearings 9 Corrosion Resistant Hybrid Ceramic Bearings 9 Non-magnetic Hybrid Ceramic Bearings 9 K series Full Complement Hybrid Ceramic Ball Bearings 9 Clean Pro PRZ Bearings • High Temperature Clean Pro Bearings • Clean Pro Bearings 9 DL Bearings • FA Bearings • High Corrosion Resistant Ceramic Bearings • Corrosion Resistant Ceramic Bearings • Ceramic Bearings 9 Corrosion Guard Pro...

Open the catalog to page 4

Development and Manufacturing Facilities By continuously incorporating new improvements, Koyo Bearings and Ceramic Bearings are applicable in more technologies than ever. Technologies are advancing rapidly and bearings are required to satisfy more complicated and varied requirements under increasingly hostile operating conditions. In response to such needs, JTEKT is committed to the development and manufacture of the EXSEV Bearing Series using the latest research / development and manufacturing facilities. JTEKT intends to supply products that live up to customers' expectations, while...

Open the catalog to page 5

Bearings: Composition and Selection 1 Ceramic Bearings and Special Steel Bearings 1 - 1 special environment such as a clean room, vacuum, high temperature application or corrosive environment, or when special ■ Load ratings and service life of ceramic bearings Special Steel Bearings …………………………………………………………………………… 10 characteristics are required, such as being non-magnetic, or insulating, or having superior high speed performance. Please consult JTEKT when using bearings in a new, unprecedented environment, or when bearings with special characteristics Koyo EXSEV Bearings are a special...

Open the catalog to page 6

1 Ceramic Bearings and Special Steel Bearings EXSEV Bearings: Composition and Selection The EXSEV Bearing Series has been developed for use in special applications where conventional bearings are not practical. The EXSEV Bearings incorporate components made from special material and use special lubricants, to be applicable in extreme special environments such as a clean room, vacuum, high temperature application, or corrosive condition, and to realize special characteristics, such as being non-magnetic, or insulating, or having superior high speed performance. The EXSEV Bearing series...

Open the catalog to page 7

EXSEV Bearings: Composition and Selection 3) Ceramic materials suitable for rolling bearings Table 1-3 shows the results of evaluating the ceramic materials in terms of their characteristics and the rolling fatigue strength. Among the ceramic materials tested, silicon nitride is the most suitable as rolling bearing material. JTEKT uses the silicon nitride produced by the hot isostatic pressing (HIP) method as the standard ceramic material for bearings. 4) Composition of ceramic bearings Koyo ceramic bearings are divided into Full Ceramic Bearings (with all components, namely, the outer...

Open the catalog to page 8

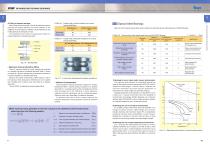

BEARINGS AND CERAMIC BEARINGS 1 2) Static load rating of ceramic bearings • Static load rating of Hybrid Ceramic Bearings 3) Impact strength of ceramic bearings The basic static load rating of a steel bearing represents a load that produces a localized permanent deformation in the rolling element/raceway contact area, impeding smooth rotation. However, ceramic materials, which are highly rigid, produce little permanent deformation. Therefore, the theory of the basic static load rating for steel bearings is not applicable to ceramic bearings. The theory of the static load rating for steel...

Open the catalog to page 9

EXSEV Bearings: Composition and Selection 4) Fitting of ceramic bearings When using ceramic bearings, it should be noted that ceramic materials are largely different from steel materials in the coefficient of linear expansion. Attention should therefore be paid to fitting stresses and temperature rises. The following are the results of evaluating the fitting of a Ceramic Bearing on a stainless steel shaft. • Table 1-6 Typical results of static strength test on ceramic bearing shaft fitting Ceramic Bearings and Special Steel Bearings • Influence of temperature During operation, bearing...

Open the catalog to page 10All KOYO BEARINGS VIERZON MAROMME (GROUPE JTEKT) catalogs and technical brochures

-

Standard Bearings

241 Pages

-

Ball & Roller Bearing

84 Pages

-

TAPERED ROLLER BEARINGS

107 Pages

-

Needle Roller Bearings

274 Pages

-

LARGE SIZE BALL & ROLLER BEARINGS

247 Pages

Archived catalogs

-

Wind Turbine Generators

4 Pages

-

High Wing Series Drive Shafts

30 Pages

-

Oil Seal & O-Ring

126 Pages

-

B1021E Slim Bearing

2 Pages

-

B1013E Ceramic Bearings

17 Pages

-

B1011E Traction Drive Unit

4 Pages

-

B1005E EXSEV Product Guidebook

13 Pages

-

Agriculture and Construction

6 Pages