Catalog excerpts

WELDING ROBOT STRUCTURAL STEEL WELDING ROBOT SYSTEM

Open the catalog to page 1

WELDING ROBOT STRUCTURAL STEEL WELDING ROBOT SYSTEM Welding robot systems for structural steel from Japan s leading welding company Kobe Steel, the only welding solutions company that develops all of its own original welding robots, welding power supplies and welding wires aims to be your No.1 partner for structural steel fabrication. Features of Structural Steel Large Assembly ASSURING Through our in-depth understanding of the welding process, our aim is to make a system that fabricators can trust and use with confidence ●W We provi rov vide de rob d ro obot ob ot syste o ysttems ms tthat m...

Open the catalog to page 2

The advantages of welding and constant voltage welding combined to give high quality welding. What is ? Wire for REGARC • Optimized to reduce slag volume and slag removal for carbon dioxide multi-pass welding. • Superior conductivity, adherence resistivity and wire feedability made possible through 's unique waveform control. • Compatible with conventional constant voltage welding. ■ The technology behind Hi |>o~g) > Typical CO2 welding REGARC' • Specialized welding equipment • Specialized welding material • Chip changer ■ Systems installed • Structural Steel Large Assembly "2-ARC" Welding...

Open the catalog to page 3

Structural Steel Large Assembly Welding Robot System ● Enhanced Features 1 Feature to realize unobserved operation for extended periods ■ Nozzle o z ccleanerr,, no ozzle o e au uto cha u anger, w a wire e cu utte u er, ch e hip cha ang a ger ((ava ailab a ble ffor b only) ccom me a m as stttand darrd d The h a arc sstarrrt prrre-c re ccheccck fu unccction u n an nd ccratter ‒ arc sta n art com mbination fea m aturre re a educces arcc sta e art e a erro ors o ● The h sslow-do w o own n sta art ffeattture e an nd w n wire e sticcck rem mova al fe a eatu e ure ccon u ntrol arcc ON N/O N OFF...

Open the catalog to page 4

il Steel Large Assembly "2-ARC" Welding Robot Systemt increase in productivity per unit area D Welding time halved • Welding time is halved compared to Single ARC welding systems. • In addition to welding, wire cut, sensing function and slag removal is automatically executed by 2 robots at the same time. Plate thickness, 9mm/0.35in, 250mm/9.84in square, 6 joint worktime comparison Semi-automated welding (3 Welders) First column Second column 3 welders work overtime until 19:00hrs for 2 columns Conventional welding system (1 robot, 1 positioner) First column Second column_) 3|Applicable also...

Open the catalog to page 5

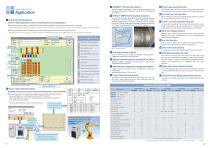

ti-purpose for high operational efficiency — • Reference layout plan Application example 12 Connection welding • Depending on the matching of the back plate, welding parameters are automatically adjusted to prevent burnt through. • Inner diaphragm • Reference installation points for each typeof connection and inner diaphragm and corresponding image (Note 1) the flange aperture requires more than 140mm when using slag automatic removal equipment. (Note 1) Maximum case - work with connection length of 2400mm installed in 2 rows (Note 2) Maximum case - work with column diameter of 500mm...

Open the catalog to page 6

lections are "fully” finished by "one set”! — Welding points ■ e-t'T-r Features Item *SRC connections are also app icable *for ground installation, the applicable 'ange increases. See the applicable range "connection" table on p10. [DConnections are fully completed in one set • A crane is not required for work reversal • Diaphragmxbeam flange (inside/outside) and beam web edge material welding is carried out continuously • The only inputs are diameter, flange thickness and leg length • Flange thickness and attachment point do not need to be entered •The flange terminal and scallop interior...

Open the catalog to page 7

Structural Steel Connection Welding Robot System layout plan Welding points HSS-Column core layout plan Structural Steel Connection 2-ARC Welding Robot System Deformed diaphragm core Round pipe core Tapered core 1 Welding time halved ■ Similar m r to the e2 2-ARC A ARC C off the e column o m llarge g assembly s m system, y e tthe e time m o of a conventional n o system ys m ccan b be h halved. v ●A Apart pa ffor w welding, g, w wire e cutt and n ssensing s g related l e w workk orr sslag g removal e o is a also executed e t by y 2 robots o o ssimultaneously. u a o sy ● *Applicable only...

Open the catalog to page 8

Application example space, big effect ! Welding points 1840mm / 6ft:Occupied space Based on the amount of surface step, the welding speed, current, aim position, torch angle, etc will be automatically calculated and welding executed Surface step detection

Open the catalog to page 9

3 ARCMANTM call function (option) ■ Support stable operation 9 Corner gap sensing function ■ During unmanned operation, the robot's finishing schedule, error messages and operation information can be sent to a designated email address. The welding quality can be improved by measuring the gap of the corner parts which are prone to variations from machining process. 10 Arc start pre-check function ■ 4 BCP325T-NBFW method software (option) ■ 1 Structural Steel Navigation ■ Useful for checking production progress and aiding planning and making quotes ● Before welding, the robot automatically...

Open the catalog to page 10

Allows for simple operation Supporting stable operation Input Screen Peripheral equipment All work data can be easily viewed in diagram form while inputting 1 Column large assembly welding ■ (Corresponding system : Large assembly 2-ARC/Single ARC) 3 Connection welding (Corresponding system : column ■ large assembly, Full-package multi, Compact) ■ Peripheral equipment for continuous un-supervised operation 2 Core welding (Corresponding system : Large assembly 2-ARC/Single ARC, ■ Nozzle auto changer Wire cutter Slag automatic clearing equipment By using 2-types of nozzle lengths, long and...

Open the catalog to page 11

Robot 6-axis multi-joint welding robot MP Positioner Both grip 1axis, possible load 2000kg / 4409lb3000kg / 6614lb4000kg / 8818lb Robot transfer equipment Left-right stroke 3.0m / 9.8ft Occupied space (Safety fence range) 2-ARC3.5mX7.2m / 11.5ftX23.6ft(5.9mX9.9m / 19.4ftX32.5ft) / Single ARC3.1mX7.1m / 10.2ftX23.3ft(5.9mX9.9m / 19.4ftX32.5ft) Robot 6-axis multi-joint welding robot ARC MAH" MP Positioner Single grip 1 axis, possible load 650kg / 1433lb 1 000kg / 2205lb Occupied space (Safety fence range) 1.8mX3.0m / (6.0mX5.9m / 19.7ft: • Peripheral equipment, welding specifications (© - ©...

Open the catalog to page 12All Kobe Steel catalogs and technical brochures

-

ALJADE™

2 Pages

-

ALHIGHCE™-83

2 Pages

-

ALHIGHCE™

2 Pages

-

ALJADE™-83

2 Pages