Catalog excerpts

<ISTLERmeasure, analyze, innovate. NC Joining Systems Solutions for Energy-Efficient and Highly Flexible Press-Fit and Joining Processes

Open the catalog to page 1

Absolute attention for tomorrow's world Kistler develops measurement solutions consisting of sensors, electronics, systems and services. In the physical border area between emissions reduction, quality control, mobility and vehicle safety, we deliver excellence for a future- oriented world and create ideal conditions for Industry 4.0. We thereby facilitate innovation and growth for - and with - our customers. Kistler stands for progress in motor monitoring, vehicle safety and vehicle dynamics and provides valuable data for the development of the efficient vehicles of tomorrow. Kistler...

Open the catalog to page 2

Resource optimization thanks to integrated process monitoring 4 Overview NC Joining Modules 6 NC Joining Module NCFT and NCFH 7 NC Joining Module NCFN, NCFE and NCFC 8 NC Joining Module NCFS and NCFR 9 Servo Amplifier IndraDrive 12 Service and applications backed by specialist expertise Joining Competence Center (JCC) 14 At our customers' service across the globe 15

Open the catalog to page 3

Transparent production processes ensure quality and reduce costs Resource optimization thanks to integrated process monitoring The integration of process monitoring has become a factor of increasing importance in industrial production. It is especially the field of press-fit and joining applications where the electromechanical NC joining systems made by Kistler tower head and shoulder above conventional systems: They play a significant role in the cutting of energy costs, the increase of system utilization and the overall boost in production efficiency. Advantages • Enhanced quality thanks...

Open the catalog to page 4

Improved economic efficiency thanks to optimized system utilization Offering a comprehensive range of cutting-edge joining systems for the force range of up to 300 kN – from compact standardized single modules to custom designs tailored to the customer's specific requirements – Kistler is setting new standards on the global market. Regardless of whether they are used for transmission and engine assembly or for the assembly of wheel carrier, wheel set and chassis: The NC joining systems made by Kistler allow for high-precision control of all traversing movements performed during assembly and...

Open the catalog to page 5

Overview NC Joining Modules Stroke depending on version (straight or angled) Note: Each NC joining module utilizes an integral absolute encoder for positioning. See the corresponding data sheet for additional technical data. * pecial versions with a stroke of up to 1,000 mm, max. force range of 600 kN or angled design are available on request S

Open the catalog to page 6

Technical data Type 2157B...

Open the catalog to page 7

Technical data Type 2153A... NC Joining Module NCFE, with cost optimized standard design Technical data Type Technical data Type

Open the catalog to page 8

Technical data Type 2152B... Measuring range 1 kN

Open the catalog to page 9

Kistler provides the optimally configured system technology for each quality assurance strategy Monitoring and control of NC Joining Modules As the core element of the joining system, the maXYmos NC monitors and controls the entire joining process. Sporting an intuitive touch screen display and an integrated sequence control, the system offers exceptional usability and an outstanding degree of flexibility making it suitable for joining process ranging from simple to highly complex. maXYmos NC controls, monitors, evaluates and documents XY curves for joining and press-fit processes, together...

Open the catalog to page 10

Measuring and Evaluation Module Can be cascaded to up to eight XY channels. The MEMs can be installed in the control cabinet. The DIM is used as the central visualization system and can be connected directly via a cable across distances of up to 5 m. Greater distances can be covered with the DIM Cable Extender Increased flexibility for the user With the integrated sequence control (Sequencer Mode), processes can be reproduced without having to rely on complex, external PLC programming. The programs can be set up rapidly and easily via the intuitive operating interface of the touch display....

Open the catalog to page 11

Technical data Technical data

Open the catalog to page 12

Evaluation objects EOs Excerpt of the evaluation elements EOs (Evaluation Objects) for maXYmos NC Entry and exit as specified. No crossing of "closed" sides allowed. Each side can be defined as entry or exit. The line may not be crossed. Otherwise, NOK and "NO-PASS" real-time signal. Entry and exit as specified. Crossing of the "closed" sides generates a real-time signal. Box detects significant curve features and their XY coordinates in the expectancy range. This information can be used as reference points for other EOs or as an input for the CALC object. Evaluation criterion is the speed...

Open the catalog to page 13

From the competent consultation through the installation to the fast supply of spare parts: Kistler is present worldwide with comprehensive service and training offerings Service and applications backed by specialist expertise Kistler delivers premium services that correspond to Kistler's high-quality product solutions and are optimally coordinated with each other. Take advantage of the strengths of Kistler’s Joining Competence Center (JCC) to avoid increased commissioning costs or achieve lasting optimization of your production. As well as performing tests, our joining system experts will...

Open the catalog to page 14

Your reliable partner throughout the entire life cycle Who knows their products better than the manufacturer? Original Service from Kistler is the comprehensive service solution directly from the world market leader in dynamic measurement technology. We deliver service quality on a par with our proven products and system solutions. At the same time, we offer graduated service packages to provide you with the right solution for your needs. Reactive maintenance Preventive maintenance First-class service – perfectly matched to the life cycle of your joining systems. Service brochure Reactive...

Open the catalog to page 15

©2023, Kistler Group 960-283e-02.23 Increased cost efficiency with cavity pressurebased systems Plastics processing Optimized process efficiency for injection molding Find out more about our applications: www.kistler.com Kistler Group Eulachstrasse 22 8408 Winterthur Switzerland Tel. +41 52 224 11 11 Kistler Group products are protected by several intellectual property rights. For more details see www.kistler.com. Kistler Group includes the Kistler Holding AG and all its subsidiaries in Europe, Asia, Americas and Australia. Find your local contact on www.kistler.com

Open the catalog to page 16All Kistler Instrumente AG catalogs and technical brochures

-

8763B

5 Pages

-

4503B

12 Pages

-

4080B

4 Pages

-

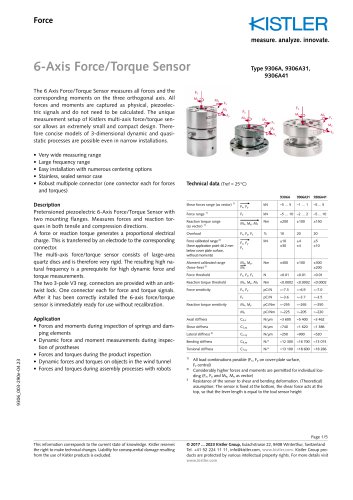

6-Axis Force/Torque Sensor

5 Pages