Catalog excerpts

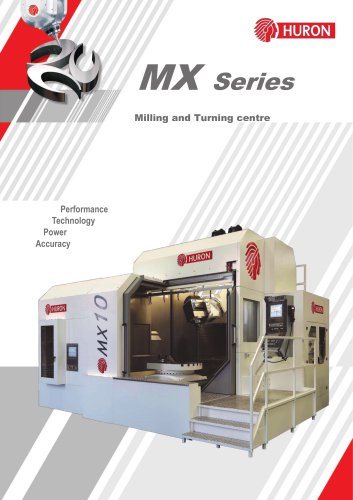

Milling and Turning centre Performance Technology Power Accuracy

Open the catalog to page 1

Powerful, Rapid, Accurate Milling (M) and Mill/Turn (MT) centre The MX multifuncion machining centre is a high flexibility machine enabling machining operations in 5 axes and on 5 sides, in one setup part clamping, from roughting to finishing, as well as turning operations. 5 axis machining for workpiece up to 12.000 kg Hard material machining in a minimal time Very high accuracy in contouring and profiles

Open the catalog to page 2

Linear axes Ballscrew with integrated system of compensation for expansion Recirculating linear roller guide shoes ensuring minimum friction and efficient axis drive Automatic grease lubrication of linear roller guides minimising the pollution of coolant Absolute linear measurement by optical encoders in conformity with norm VDI/DGQ 3441 Head and Spindle Head equipped with integrated torque motor Head on a 45° plane allowing tilting from -45° up to +180° Spindle orientation : from vertical to horizontal, through all intermediate positions Powerful spindle with high torque...

Open the catalog to page 3

Standard head and spindle Standard universal head (A axis) MX 8/10/12 M/MT MX 12L M Rotating speed Torque : working / clamping Measuring on axes Resolution Débattement axe A Axe broche / plan chariot Axe broche / plan table Standard spindle Taper HSK 63A Rotating speed 100 - 14.000 rpm Power (S6/S1) 29 kW (S1) Torque (S6/S1) 277 (S1) Characteristic speed 1.000 rpm Equipments Air wall for spindle protection Control captor for angular positioning of the spindle Electrospindle cooling system Mechanical clamping with spring rings Tool release with hydraulic control Life greasing of...

Open the catalog to page 4

Alternatives for spindles (universal head of fork head) When fork head, clearance of B axis is limited from -105° up to +10° Taper Rotating speed Power - Torque (S6/S1) Characteristic speed MX 10/12 M/MT - MX 11 - MX 12L M - MX 16/20 M 8.000 rpm Taper Rotating speed Power - Torque (S6/S1) Characteristic speed Taper Rotating speed Power - Torque (S6/S1) Characteristic speed

Open the catalog to page 5

MX 10/12 M B axis clearance Resolution Rotating speed Torque : working / clamping B axis, parallel to the Y axis allows the evolution of the spindle around the horizontal axis The axis has a torque motor directly connected to the rotating parts ensuring a movement without backlash and a very accurate positioning Universal head for Mechanical head / Alternative MX 10/12 M/MT - MX 12L M A axis clearance Resolution Rotating speed Torque : working / clamping Universal milling head with 1 rotating axis, on a 45° plane Very well suited for the hard material machining Allow an important...

Open the catalog to page 6

Spindle 8.000 rpm with fork head Taper Rotating speed Power - Torque (S6/S1) Characteristic speed Mechanical spindle 6.000 rpm with universal head Taper Rotating speed Power - Torque (S6/S1) Characteristic speed Tools changers MX 8/10/11/12 M - Tool magazine is an horizontal chain type - Automatic load/unload of the tool is made in vertical position Pockets quantity / Taper 60 / HSK 63A Max. length Max. Ø contiguous / non contiguous Max. weight : tool / in magazine Tool changing time : tool / tool - chip / chip Alternatives : Tools changers MX 8/10/11/12 M MX 12L M - Magazine with 2...

Open the catalog to page 7

Series M version Standard Table dimension Max. machining volume (ØxH) Admissible load Rotating speed Torque : working / clamping Clamping system T slots Central boring Table dimension Max. machining volume (ØxH) Admissible load Rotating speed Torque : working / clamping Clamping system T slots Central boring Table dimension Max. machining volume (ØxH) Admissible load Rotating speed Torque : working / clamping Clamping system T slots Central boring Table dimension Max. machining volume (ØxH) Admissible load Rotating speed Torque : working / clamping Clamping system T slots Central boring (*)...

Open the catalog to page 8

Interference diagrams with standard table MX 8 M Interference diagrams with palletized table MX 8 M Standard table Palettised table

Open the catalog to page 9

Extension of the range - MX 16, MX 20 M In order to allow our customers to machine extremely large parts, the MX range has been extended to include extra-large models, with MX 16 and MX 20. The larger workpiece clearance will be appreciated by some of our customers, particularly in the aeronautic and energy industries. Heads and spindles Offer identical to other machines in the range Tool changers Automatic loading/unloading of tools is made in vertical position Qty of housings Type Taper Tool dimension Max. Ø tool Max. length Max. weight of tool Max. weight in magazine Tool changing time...

Open the catalog to page 10

Table dimension Max. machining volume (ØxH) Admissible load Distance between column Rotating speed (S6) Torque : Working (S6) / Clamping Clamping type Central boring MX 16 M - Head/table positioning

Open the catalog to page 11

Automation For higher productivity, increase production speeds and optimise machining cycles, we offer a variety of palletizing configurations. The processes are independent, safe and reliable. Palletizer attached to the front of the machine Optimal operator access to the machine Constant visibility over the working area Safeguard for easy, ergonomic pallet loading/unloading from above and from the front of the machine Pallet device with 2 pallets and available up to 4 pallets for MX 16 and

Open the catalog to page 12

or how to manage tool life This cycle provides automatic tool checking during machining or at tool change. If critical wear or a broken tool is detected, the system automatically triggers the replacement of the tool at the most appropriate time. It therefore safeguards the integrity of the workpiece and the cutting tools and optimizes tool use. The profitability of the machine is increased by reducing downtime and tooling costs. MAIN FEATURES Automated tool measurement, inspection and replacement done in the machining process No change to the NC program Implemented by HURON ...

Open the catalog to page 13

Technical characteristics Linear axes X / Y / Z MX 8 M MX 8 MT MX 10 M MX 10 MT MX 11 M MX 12 M MX 12 MT Travels mm 1.160x1.000x900 1.200x1.200x1.000 1.250x1.250x1.000 1.200x1.600x1.000 Rapid feedrates m/min 42 42 40 42 Acceleration per axis m/s² 4 4 4 4 Rotating A axis - Universal head MX 8 MX 10 MX 11 MX 12 Rotating speed rpm 100 100 30 100 Torque : Work / Clamping Nm 2.120 / 2.500 2.120 / 2.500 7.000 / -2.120 / 2.500 Rotating C axis - Table MX 8 M MX 8 MT MX 10 M MX 10 MT MX 11 M MX 12 M MX 12 MT Rotating speed rpm 50 500 65 500 30 50 250 Table dimension mm 1.000x800 Ø 800 1.250x900 Ø...

Open the catalog to page 14