Catalog excerpts

Series 5 axes machining centres Mobile traverse, high performance Performance Technology Power Accuracy

Open the catalog to page 1

Series Powerful, Rapid, Accurate 5 axes Gantry machining centre Hgh performance The 5-axis Gantry milling centre is a very large machine that allows machining operations on 5-axis and 5-sided to be carried out in one setup part clamping, from roughing to finishing. It is particularly suitable for large complex parts intended for machining molds, dies, stamping tools, models and precision parts in the automotive, aeronautical and industrial mechanics industries. − Very high accuracy in contouring and profiles Complete automation of the machine Structure : Rigidity and Accuracy − Gantry...

Open the catalog to page 2

Head / Rotating axes − Direct drive by torque motors for perfect synchronization with linear movements − Direct mounting angular encoders offering high positioning accuracy on both axes − Continuous high speed, high accelerations, no backlash and no wear − Rigidity: high locking torque thanks to hydraulic brakes, allowing the spindle power to be fully exploited during roughing operations − Powerful and high-torque spindle for high chip removal − Vibration monitoring during machining allowing a secured work for the machine elements, for the tool as well as for the part Environment Ergonomics...

Open the catalog to page 3

Series Standard head and spindle − − − − − − − − Fork head with 2 orthogonal moving axes B axis : evolves in the Z and Y-Z plane and swings around a horizontal axis C axis : moves in the X-Y plane and rotates around the vertical axis Z Angular encoder in the axis for high positioning and repeatability accuracy Torque motors for backlash-free and wear-free movings High clamping torque for heavy roughing Possibility to reach negative angles Allow the machining with 5 continuous axes Vibration monitoring Vibration monitoring during machining allowing a secured work for the machine elements,...

Open the catalog to page 4

Spindle alternatives with standard head Spindle alternatives with alternative head Electrospindle 15.000 rpm Taper HSK 100-A Rotating speed 15.000 rpm Power (S6/S1) 45 / 45 kW Torque (S6/S1) 145 / 120 Nm Characteristic speed 3.580 rpm Electrospindle 12.000 rpm Taper HSK 100-A Rotating speed 12.000 rpm Power (S6/S1) 86 / 70 kW Torque (S6/S1) 235 / 190 Nm Characteristic speed 3.500 rpm Electrospindle 18.000 rpm Taper HSK 63-A Rotating speed 18.000 rpm Power (S6/S1) 70 / 56 KW Torque (S6/S1) 111 / 89 Nm Characteristic speed 6.000 rpm Electrospindle 24.000 rpm Taper HSK 63-A Rotating speed...

Open the catalog to page 5

Series The table Table allowing large parts machining. KXG 30-15 Table dimension Admissible load Distance between portal

Open the catalog to page 6

Standard tool changer Chain with 2 wheels The automatic loading/unloading of tools is done vertically. Number of housings Taper Tool size Ø - length - weight Max. weight in the magazine Tool changing time : tool to tool - chip to chip Number of housings Tool size Ø - length - weight Max. weight in the magazine Tool changing time : tool to tool - chip to chip Number of housings Tool size Ø - length - weight Max. weight in the magazine Tool changing time : tool to tool - chip to chip TWIN version - Pendulum machining (optional) Adaptability and flexibility of the workspace to easily meet the...

Open the catalog to page 7

Technical characteristics Rotating axes (B, C) − Positioning (P) − Repeteability (Ps medium) Tools changer Number of housings Ø - Length - Weight Tool changing time : tool to tool - chip to chip Overall measurements (Doors opened + conveyor) Width Depth Height Weight of the machine Optional equipments Extension of Z travel to 1.250 mm - Various spindles and heads - Various tools changers - Pendulum machining - T-slots on table Washing rail - Microspraying - Air blowing - Part probe - Tool probe - Oil mist extraction - Oil separator - Pressurization of measuring scales INDIA Jyoti CNC...

Open the catalog to page 8All HURON GRAFFENSTADEN catalogs and technical brochures

-

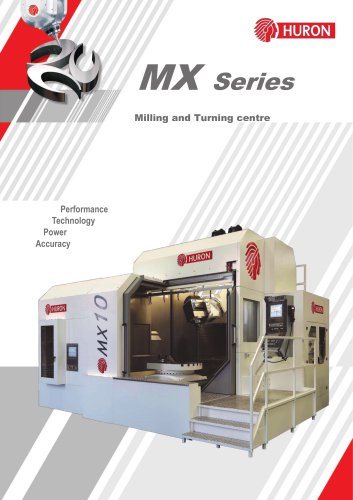

MX Series - English - 2019

16 Pages