Catalog excerpts

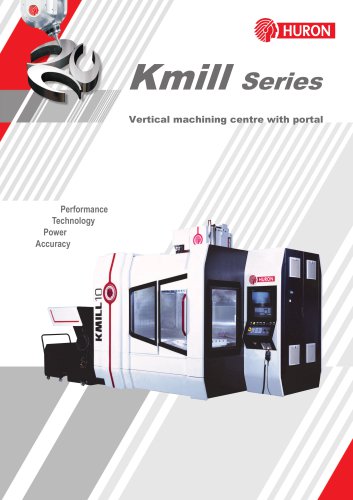

Large Series Vertical milling centres 5 axes, high speed, fixed portal Performance Technology Power Accuracy

Open the catalog to page 1

Large Series KX Large, a range of very high performance milling machines for 5-sided and 5-axes machining of complex parts. The choice of fixed portal architecture makes it possible to offer a machine with maximum rigidity for extremely accurate machining in various and hard materials. The working area accept workpieces with weight up to 20 tons and machining volumes up to 4.080 x 2.180 x 1.550 mm on the 5 faces. The modular design and the many alternatives and equipments offered make it easy to meet all customer requirements. − High performances in roughing as well as in finishing − High...

Open the catalog to page 2

Rigid and robustness structure − Fixed portal − Mobile parts : • KX 50 : slide, saddle, bed/table and portal in melting • KX 100/200 : slide and saddle in welded steel ; bed/table in melting • KX 300 : slide and saddle in welded steel, bed/ table and portal in concrete − The architecture, structure and materials used are optimized to absorb cutting forces and those induced by the accelerations of moving bodies. This results in high stability and excellent dynamic behavior during machining, which results in optimized cutting and high fidelity in the execution of contours and shapes on all...

Open the catalog to page 3

Large Series Fork head and electrospindle − − − − − − − − Accurate positioning and repeatability for complex workpieces Angular encoders in the axis for accurate positioning and repeatability Torque motors for dynamic movements without backlash and wear High clamping torque for high roughing Possitility of reaching negative angles Axial/radial tool stiffness guaranteed Machining of deep pockets thanks to the use of long tools Spindle and machining secured thanks to vibration monitoring KX 50 M/L Swivelling of axes Rotating speed (B, C) Clamping torque (B, C) Working torque − B axis − C axis...

Open the catalog to page 4

Electrospindle without Hirth-Blocking 10.000 rpm - HSK 100A

Open the catalog to page 5

Large Series The table Mobile table with large working area allowing the machining of large parts and the use of a wider range of tool lengths for the same clamping. Table dimension Machining volume (**) − length x width − height Admissible load Rapid feedrate X / Y / Z Qty of slots Reference slot Other slots Distance between slots (*) with maximal acceleration (**) 5-sided machining with a 100 mm tool length KX 300 Rack-and-pinion table drive perfectly suited for long strokes and heavy loads. Increases rigidity. Interferences diagrams KX 50 KX 50 M - Standard table

Open the catalog to page 6

Interferences diagrams KX 100 / 200 / 300 KX 100 - Standard table

Open the catalog to page 7

Large Series Tools changers The load/unload of tools is made in vertical position KX 50 M/L Qty of housings Taper Tool dimension Ø - length - weight Max. load in magazine Tool changing time : tool/tool - chip/chip 100 / 190 mm - 300 mm - 8 kg 160 kg Picture of KX 50 tools changer Alternatives KX 50 M/L For the machining of deep pockets, the rigidity of the machine allows the use of long tools.(with HSK 100-A taper) Combined with vibration monitoring, it is possible to obtain finished parts of very high quality. Qty of housings Taper Tool dimension : Ø Length Weight Tool changing time :...

Open the catalog to page 8

HURON numerical controller cycles or how to manage tool life This cycle provides automatic tool checking during machining or at tool change. If critical wear or a broken tool is detected, the system automatically triggers the replacement of the tool at the most appropriate time. It therefore safeguards the integrity of the workpiece and the cutting tools and optimizes tool use. The profitability of the machine is increased by reducing downtime and tooling costs. MAIN FEATURES • Automated tool measurement, inspection and replacement done in the machining process • No change to the NC program...

Open the catalog to page 9

Large Series Performance Looking for a simple and effective solution? HURON offers you a complete standard solution to allow you to realize your parts at a competitive price. • • • • • • • • • • • • • Moving table Fork head equipped with electrospindle Tools changer Chips conveyor and washing device for chips recover channels Washing gun Low coolant by nozzles Operator panel Portable electronic handwheel Complete safeguard Oils for first feeling (excluding emulsion) Cylinders for leveling 1 set of technical documents 12 months warranty Automation For higher productivity or greater accuracy...

Open the catalog to page 10

Technical characteristics Linear axes X / Y / Z X travel Y travel Z travel Rotating axes B, C - Head Swivelling of B axis Rotation of C axis Rotating speed Clamping torque Working torque Rapid feedrates Table Dimension mm Max. admissible load kg Qty of slots Reference slot mm Other slots mm Distance between slots mm Spindle Spindle speed rpm Taper Power - Torque kW - Nm Characteristic speed rpm Accuracies (VDI DGQ 3441) Linear axes (X/Y/Z) − Positioning (P) mm − Repeatability (Ps medium) Rotating axes (B, C) − Positioning (P) sec sec − Repeatability (Ps medium) Tools changer Qty of housings...

Open the catalog to page 11

INDIA Jyoti CNC Automation Ltd G-506 & 2839, Lodhika, G.I.D.C., Vill. Metoda, Dist: Rajkot - 360 021 +91-2827 287081/082 info@jyoti.co.in CANADA Huron Canada 105-85 rue St-Charles Ouest Longueuil, Québec, J4H 1C5 +1 514 448 4873 +1 514 448 4875 infocanada@huron.fr TURKEY Huron Graffenstaden Türkiye irtibat bürosu Merdivenköy Mah. Dikyol Sok. No:2/A Kat:1 No:101/102 34387 Kadıköy / Istanbul +90 (0)216 463 33 67 info-turquie@huron.fr 2019-12 - KX Large Series / English / HURON All descriptions, data and photos are supplied for information only. Huron Graffenstaden reserves the...

Open the catalog to page 12All HURON GRAFFENSTADEN catalogs and technical brochures

-

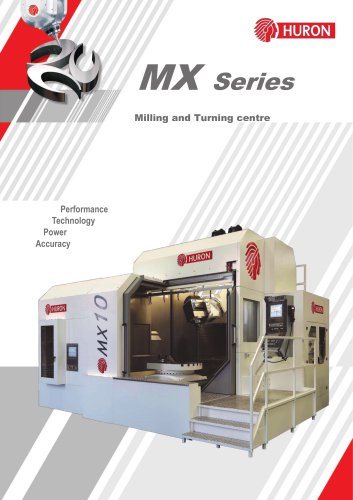

MX Series - English - 2019

16 Pages