Catalog excerpts

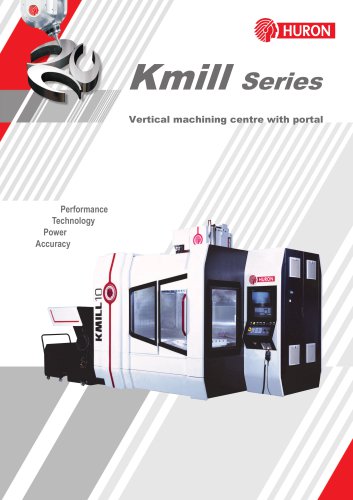

Series Vertical machining centre with portal Performance Technology Power Accuracy

Open the catalog to page 1

Kmill Series The Kmill range, portal-structured machine, incarnates the most efficient concept for machining complex parts along three axes, from roughing to finishing. This Series of machines combines dynamic action and precision for top quality surface finishes, especially for 3D shapes for moulds, forgings and tooling. − 3 axes machining for workpiece up to 1.500 kg − Hard material machining in a minimal time Structure : Rigidity and Accuracy − Reinforced portal ribbed cast iron structure for greater rigidity − Cast iron with a high mechanical performance which maximises structure...

Open the catalog to page 2

Electrospindle Taper Rotating speed Power (S1/S6) Torque (S1/S6) Characteristic speed Tool changer The loading/unloading of tools is made in vertical position Type Number of housings Taper Tool size Max. Ø of tool Max. length Max. weight Tool changing time tool to tool - chip to chip Table Table size Admissible load Number of T slots Distance between slots Size of refering slot Size of other slots Distance from floor to top table Distance min/max spindle face / top table Distance under portal

Open the catalog to page 3

Technical specifications Accelerations on axes Table Table size Admissible load Spindle Rotating speed Taper Power / Torque Characteristic speed Accuracy (VDI DGQ 3441) − Positioning (P) − Repeatability (Ps medium) X - Y - Z = 0,010 X - Y = 0,015 / Z = 0,007 X - Y - Z = 0,005 X - Y = 0,007 / Z = 0,005 with measuring scales (option) − Positioning (P) − Repeatability (Ps medium) Tools changer Qty of housings Tool length Tool Ø Weight of tool Overall measurments (Doors opened + Conveyor) Width Depth Height Weight of the machine Optional equipments Taper HSK 63-A - Medium coolant pressure 20...

Open the catalog to page 4All HURON GRAFFENSTADEN catalogs and technical brochures

-

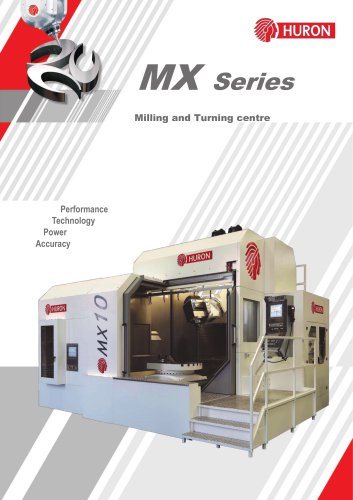

MX Series - English - 2019

16 Pages