Catalog excerpts

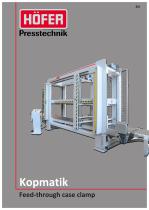

Kopmatik Feed-through case clamp

Open the catalog to page 1

Feed-through case clamp fast, flexible and universal Highlights: • 150 up to 3500 kg pressure force • 200 mm/sec adjusting speed Economic and flexible - a self-adjusting case clamp that can cope with the tight requirements of continuous line production. The throughfeed case clamp KOPMATIK will help reducing costs and time spent on set-up and adjustments. The workpiece is scanned visually and the machine will self-adjust. You determine pressing time and pressure. SAFETY is a priority Safety that protects without hindering is of paramount importance at HOFER. All case clamp models meet the EC...

Open the catalog to page 2

Overview Base frame The base frame is made of heavy steel beams. All surfaces are machined with high precision machines. On the lower base there is a transport belt. The drive occurs via a gear motor. The driving shaft is rubberized. A frequency converter enables to start up and slow down of the belt less jerky. Horizontal and vertical pressure beam The horizontal pressure element is a sturdy table construction with a whole contact area. The contact area is made of a 6 mm thick compact plate, which is easy to clean. The upper pressure element is mounted on the horizontal pressure beam, and...

Open the catalog to page 3

Operation panel The operating elements are situated in the operator console, beside the machine. Adaptations of the software according to customer requirements would be possible at any time. Pressure force The adjustment of the pressure force is done on the operating panel. The pressures of the horizontal and vertical pressure beam can be differently adjusted. Height detection Sensors detect the respective height of the cabinet. Then, the horizontal pressure wall is preset on this level. Commission step work is optimally possible. Length detection A sensor detect the length of the cabinet....

Open the catalog to page 4

Standardmodel Pressure force [kg] Working dimension max. [mm] Working height [mm] Adjusting speed [mm/sec] Belt speed [m/min] Power horizontal pressure wall [kW] Power vertical pressure wall [kW] Power conveyor belts [kW] Place requirements [mm] Total weight approx. [kg] Special sizes and special equipement on request. Options • Automatic central pressure elements • Set-up station • Rotary table • Angular transfer system (in combination with rotary table) • Assembly station • Customized solutions of the machine up to a complete production line Layout of a...

Open the catalog to page 5

Presstechnik HOFER produces and assembles all machine components in their 10.000 m2 state-of-the-art production facilities. Quality from Austria HOFER PRESSTECHNIK GmbH Pramerstrasse 11 4753 Taiskirchen AUSTRIA +43 7764 7351-0 +43 7764 7570 office@hoefer-maschinen.com www.hoefer-maschinen.com

Open the catalog to page 6All HÖFER PRESSTECHNIK GMBH catalogs and technical brochures

-

FLEXER

3 Pages

-

FSP

8 Pages

-

KOPTRONIK

6 Pages

-

KP2000

4 Pages

-

HKP

6 Pages

-

HDP

6 Pages

-

EXPERT

6 Pages

-

MHP

6 Pages

-

Special Machines

2 Pages

-

Machines for wood-working

42 Pages