Catalog excerpts

THE WORLDWIDE REVOLUTION IN THE HISTORY OF MACHINE TOOLS SCIENTIFIC INSTRUMENTS BY FPT RESEARCH DEPARTMENT EMPOWERING INNOVATION

Open the catalog to page 1

INTRODUCTION At the end of the installation of each machine, it is issued a testing certificate attesting the geometrical accuracy of the machine according to ISO3070 and ISO10791 norms and the axis accuracy according to VDI/DGQ3441 norm. The machine starts to work but, as the time goes by, the initial geometrical accuracy can be jeopardized by several reasons, among which: ground setting or foundation settlement, possible incorrect use of the machine leading to collisions, wear-out of some components, earthquake. If a geometrical control becomes necessary, it is required the intervention...

Open the catalog to page 3

4 INTERNATIONAL PATENTS 5 years of technical and scientific research carried out by the engineers of FPT Industrie S.p.A. in collaboration with the CNR, have led to the development of an innovative device: EXTRACAL. Considering the high inventive content, inventions have been protected by 4 INTERNATIONAL PATENTS. Thanks to an important engineering work, EXTRACAL technology is now ready to be used on an industrial scale in extreme operating conditions.

Open the catalog to page 4

SYSTEM COMPONENTS EXTRACAL consists of a dedicated complex electronic system, a special software developed by FPT Industrie S.p.A. and active/ passive laser emitters called OLS (Optics Laser Station) that in detail are constituted by: Datum station. The emitter/receiver placed in this position is strongly fixed on the same foundation where the machine have been anchored. This station is the datum and storage for all measures; An OLS positioned on the lower part of the moving column of the machine. It has the function to reflect the laser beam in order to execute the measuring of the first...

Open the catalog to page 5

SYSTEM COMPONENTS Each system components is housed in a solid and robust case that allows the use in any operating condition. Moreover, the devices described at point 2 and 3 are placed within the cabin of the machine to further increase the axis protection. When the use of laser is required, pneumatic shutters connect the laser beams to each single device. WATER PROOF IMPACT RESISTANT WATER PROOF DUST PROOF IMPACT RESISTANT DUST PROOF

Open the catalog to page 6

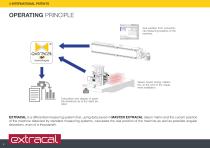

OPERATING PRINCIPLE Just after the installation of a new machine, therefore in ideal conditions (geometrical tests executed with positive results according to ISO3070, ISO10791 and VDI/DGQ3441 norms), machine axes are moved through all the working volume by a whole automatic cycle so that EXTRACAL system can create a datum matrix. This matrix, called MASTER EXTRACAL, referring to an absolute datum system (datum station) external to the machine, is saved and used for the normal functioning of the system, namely for subsequent measures.

Open the catalog to page 7

OPERATING PRINCIPLE Axis position from conventional measuring systems of the machine. WATER PROOF DUST PROOF IMPACT RESISTANT Values saved during calibration at the end of the equipment installation. Calculation and display of possible deviations as to the rated position. EXTRACAL is a differential measuring system that, using data saved in MASTER EXTRACAL datum matrix and the current position of the machine detected by standard measuring systems, calculates the real position of the machine as well as possible angular deviations, even of a thousandth. 防水

Open the catalog to page 8

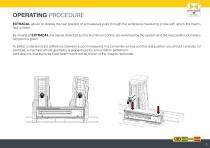

OPERATING PROCEDURE EXTRACAL allows to display the real position of a measured point through the workpiece measuring probe with which the machined is fitted. By means of EXTRACAL the values detected by the Numerical Control are reworked by the system and the real position of measured point is given. To better understand the difference between a point measured in a conventional way and the real position you should consider, for example, a machine whose geometry is jeopardized by a foundation settlement. Let’s assume that surfaces have been machined as shown in the images hereunder.

Open the catalog to page 9

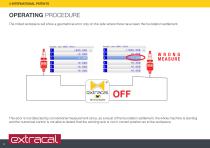

OPERATING PROCEDURE The milled workpiece will show a geometrical error only on the side where there have been the foundation settlement. This error is not detected by conventional measurement since, as a result of the foundation settlement, the whole machine is slanting and the numerical control is not able to detect that the working axis is not in correct position as to the workpiece.

Open the catalog to page 10

OPERATING PROCEDURE EXTRACAL system, having saved in the MASTER EXTRACAL matrix the geometrical characteristic certified according to ISO3070, ISO10791 and VDI/DGQ3441 norms during the initial calibration phase, provides the real position of measured points compared to an absolute external measuring system. By means of EXTRACAL system, the machine can correctly execute the subsequent finishing machining of the workpiece because it is able to identify and measure the possible geometric errors due to the foundation settlement.

Open the catalog to page 11

PERFORMANCES AND AVAILIBILITY EXTRACAL system has the following characteristics: • Resolution of each single OLS sensor less than a thousandth of mm; • Angles are calculated from linear measures, therefore the angular resolution is on the order of 10-5 rad; • Hardware developed in order to be immune to stresses, dust or fluids normally presents in a machine tool; • FPT Industrie S.p.A. software managing the calibration, the machining with compensation and the measure of the workpiece; • Available with machines equipped with NC Heidenhain and Siemens; • All components are manufactured by FPT...

Open the catalog to page 12

REFERENCE CALIBRATION WITH EXTRACAL STEP 1 X AXIS

Open the catalog to page 13

SIMULATION OF FOUNDATION SETTLEMENT STEP 2

Open the catalog to page 14

MEASURE WITHOUT EXTRACAL STEP 3

Open the catalog to page 15

MACHINE CHECKING WITH EXTRACAL

Open the catalog to page 16

COMPENSATION WITH EXTRACAL STEP 5 Punti reali Real points Compensated points Punti compensati

Open the catalog to page 17

SIMULATION OF FOUNDATION SETTLEMENT Y (mm)

Open the catalog to page 19

MEASURE WITH EXTRACAL STEP 8 0,5 Real points Punti reali Compensated points Punti compensati Dati e caratteristiche del presente catalogo non sono impegnativi. Il costruttore si riserva di modificarli senza preavviso in qualsiasi momento. - Data and features in the present catalogue are not binding. The producer reserves the right to alter them without advance notice at any time. - Die in diesem Katalog angeführten Daten und Angaben sind unverbindlich. Der Hersteller behält sich das Recht zur Änderung ohne vorherige Benachrichtigung vor. - Les données et caractéristiques du présent...

Open the catalog to page 20All FPT INDUSTRIE SPA catalogs and technical brochures

-

Kenta

16 Pages

-

CASTEL

7 Pages

-

VERUS

9 Pages

-

TESSEN

7 Pages

-

RONIN EVO

11 Pages

-

Dinox 350 iat

2 Pages

-

Dino 220 iat

4 Pages

-

RAID

5 Pages

-

DINOMAX

20 Pages

-

DINO

7 Pages

-

Mares 4.0+

12 Pages

-

STINGER double rotating

9 Pages

-

TESSEN evo

7 Pages

-

SPIRIT

13 Pages