Catalog excerpts

TECHNICAL SPECIFICATIONS VOLUME 2 ULTIMATE FIBEROPTIC MINIMAX FREEDOM

Open the catalog to page 1

TABLE OF CONTENTS GENERAL INFORMATION FISCHER FIBEROPTIC SERIES

Open the catalog to page 2

Connector overview OPTICAL PERFORMANCE EASY CLEANING Push-pull Quick-release Brass Aluminum Nickel Anthracite / Black (ULTIMATE 80) Chrome over Nickel Fiber optic / Low voltage (hybrid) Contact: Crimp / Solder / PCB Contact: Optical termini / Solder (hybrid) Sealing level Mating cycles Locking Shell material Plating Technical specifications for our Fischer Core Series can be found in VOLUME 1. Technical Specifications

Open the catalog to page 3

Connector overview HIGH-DENSITY MINIATURIZATION EASY MATING HIGH-SPEED DATA TRANSFER EASY CLEANING EASY INTEGRATION Push-pull Screw-locking / Quick-release Brass Stainless Steel 316L Chrome over Nickel Anthracite Nickel Anthracite Nickel Contact: Solder / PCB / Wires / ZIF Sealing level Mating cycles Locking Shell material Plating Plug ø [mm] Number of contacts AWG Contact type

Open the catalog to page 4

Product specifications ORIGINAL PUSH-PULL LOCKING SYSTEM OTHER LOCKING SYSTEMS Fischer Connectors’ original push-pull automatic locking system is widely adopted by the industry for its ease of use, safety of mating and speed in connection and disconnection. LANYARD Combines push-pull automatic locking with an emergency release lanyard. outer sleeve Receptacle Receptacle flexible fingers Receptacle Receptacle outer sleeve outer outer sleeve sleeve Plug Plug flexible fingers plug body flexible flexible fingers fingers groove groove MATING The plug has an outer sleeve, with flexible fingers,...

Open the catalog to page 5

Product specifications SEALING CATEGORIES The IP (Ingress Protection) classification system provides a reliable method of comparing relative levels of sealing between various connector products. The protection level offered by a typical envelope is described in IEC 60529, published by the International Electrotechnical Commission (IEC). While the first number describes the level of protection from solid objects, the second one relates to protection from liquids. The digits indicate conformity with the conditions summarized in the tables aside. Protected against solid objects greater than 50...

Open the catalog to page 6

Product specifications O-rings COMMONLY USED SEALING LEVELS IP50 indoor unexposed applications IP68 watertight sealing Hermetic sealing Each requires different sealing levels and, therefore, different connector solutions. IP50 INDOOR / UNEXPOSED APPLICATIONS Typically for indoor or industrial applications, the required sealing level is IP50, since the device needs to be protected against dust but not exposed to water. The IP50 rating can be improved with additional accessories like boots or protective sleeves. IP68 WATERTIGHT SEALING Typically for applications requiring outdoor use where...

Open the catalog to page 7

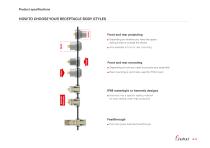

Product specifications HOW TO CHOOSE YOUR RECEPTACLE BODY STYLES Front and rear projecting Depending on whether you need the space saving inside or outside the device Also available in front or rear mounting Front and rear mounting Depending on how you need to process your assembly Rear mounting is commonly used for PCB mount SEALING MATERIAL IP68 watertight or hermetic designs Hermetic has a specific sealing material for best sealing under high pressures Feedthrough Hermetic panel bulkhead feedthrough

Open the catalog to page 8

Product specifications MATERIALS MATERIAL NAME MAIN ATTRIBUTES SHELL MATERIAL Chromium-plated brass Salt mist and mechanical resistance, cost efficiency, electrical conductivity Stainless steel Cleaning / Radiation Corrosion resistance, surface cleanability, nuclear radiation and mechanical resistance Sterilization in autoclave, EtO, Cidex, gamma radiation, Steris®, Sterrad® Electrical insulation, low temperature manipulation Cost efficiency Disposable solutions, medical applications CONTACT BLOCK MATERIAL PEEK High temperature High temperature, high chemical and high radiation resistance...

Open the catalog to page 9

Product specifications A/Z POLARITY To protect users from contact with dangerous voltage, most of Fischer Connectors’ products are available in two versions : STANDARD A POLARITY The contacts of the receptacle are protected against accidental touch. Recommended when voltage is present on the receptacle. INVERTED Z POLARITY The contacts of the plug are protected against accidental touch. Recommended when voltage is present on the plug.

Open the catalog to page 10

Product specifications TEST VOLTAGE & OPERATING VOLTAGE Operating voltage Operating voltage Creepage distance & airgap Test voltage Typical scatter of breakdown voltage values Breakdown voltage BREAKDOWN VOLTAGE Maximum voltage difference that can be applied before the occurrence of a disruptive discharge between mutually insulated portions of a connector or between insulated portions and the ground. TEST VOLTAGE (or withstanding voltage) Voltage level at which the connector is tested during the qualification test. This value represents the upper physical limit. It is usually set at 75% of...

Open the catalog to page 11

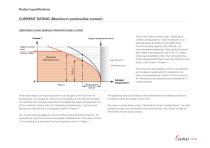

Product specifications CURRENT RATING (Maximum permissible current) DERATING CURVE DERIVED FROM THE BASIC CURVE Current l Upper temperature limit Upper current limit (wires, cable) (Derated) Operating area Basic curve The current values listed under “Electrical & contact configurations” were measured in our test laboratory according to IEC 60512-5-2: Current-carrying capacity test, Test 5b: Current-temperature derating. They are the currents that create a temperature rise of 40 °C (unless otherwise specified) within the connectors due to the self-generated heat, and they belong to the basic...

Open the catalog to page 12

Product specifications HIGH FREQUENCY SIGNAL & DATA TRANSMISSION INPUT Challenges in data transmission When a signal is emitted at the transmitter, it must undergo minimal distortion across the system (transmitter, connectors, cable, receiver) to be properly recovered at the receiver. DATA TRANSMISSION PRINCIPLES Types of signal distortion across the transmission link: Return loss: When the impedances of two interfaced media do not match (i.e., transmitter/connector, connector/cable, ...), some parts of the signal will reflect back towards the source and be lost. The amount of this loss...

Open the catalog to page 13All Fischer Connectors catalogs and technical brochures

-

Fischer Core Series Brass

178 Pages

-

Fischer Core Series Broadcast

29 Pages

-

Fischer Core Series Alulite™

32 Pages

-

Connectors Overview

2 Pages

-

Cable Assembly Solutions

4 Pages

-

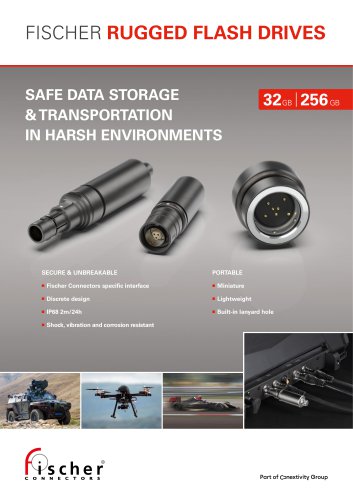

Fischer Rugged Flash Drives

4 Pages

-

Fischer MiniMax™ Series

27 Pages

-

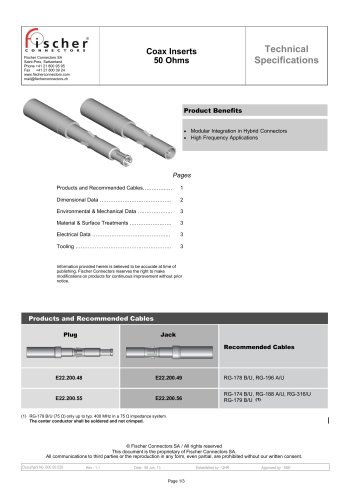

Coax Inserts 50 Ohms

3 Pages

-

Fischer FiberOptic Series

32 Pages

-

Fischer UltiMate™ Series

45 Pages

-

Technical Specifications Volume 1

293 Pages