Catalog excerpts

THE FACTORY AUTOMATION COMPANY α-DiB Plus series | α-DiBadv Plus series High-performance vertical machining centre Automated machining for more versatile milling, drilling and tapping WWW.FANUC.EU

Open the catalog to page 1

intelligent automation – 100% FANUC Lift up to 2.3 tons – choose from over one hundred robots with payload capacities ranging from 0.5 kg to 2.3 tons. FANUC ROBOCUT wire EDM machine for mould making, tooling and cutting of parts. Multi-robot welding cells – easy automated welding thanks to seamless connectivity and a single user-friendly CNC interface. CO2 laser packages for efficient automated laser cutting. No need for safety fences – FANUC collaborative robots allow easy integration into human workspaces for even more manufacturing efficiency and improved health and safety. Visual bin...

Open the catalog to page 2

The new-generation ROBODRILL promises unrivalled quality and precision at great hourly rates. With an unbeatable tool change time of 0.7 seconds and a turret capable of handling tools weighing 4 kg, the new advanced version is the fastest and strongest vertical machining centre on the market. With the shortest cycle times on most machining operations, all ROBODRILL machines are real high-speed all-rounders, offering incredible performance and unbeatable efficiency. • ultrafast tool changer • extraordinarily stable machining and accuracy • easy automation • optimal acceleration and...

Open the catalog to page 3

The efficient all-rounder for a wide range of industries When it comes to new products or changing product numbers, ROBODRILL’s inherent versatility becomes a tangible asset. Instead of relying on a dedicated transfer machine, spreading your machining across several ROBODRILLs allows for higher flexibility across a wide range of applications and industries – saving you money in the process. Designed to adapt to your every need, FANUC ROBODRILL has a flexibility that covers 3, 4 or even 5 simultaneous axes, thus representing an excellent supplement to your production facilities. Free up...

Open the catalog to page 4

The multipurpose solution to your efficiency needs Designed to meet every need, the ROBODRILL α-DiB Plus series comprises completely re-designed models in S, M and L sizes, available in either standard or advanced versions. With a rigid servo drive control and a highly dynamic BBT30 spindle, these high-speed all-rounders are suitable for all vertical machining applications, from short production runs requiring fast turnaround times to flawless mass production. Its future-proof versatility and easy adaptability make the ROBODRILL the best-selling machine in its class. High-performance...

Open the catalog to page 5

Features of the ROBODRILL α-DiB Plus series Cycle time reduction Tool-to-tool changes on ROBODRILL α-DiB Plus models are extremely fast – ranging from 0.9 seconds on our standard versions to an incredible 0.7 seconds on the advanced. Cut to cut means 1.5 seconds for standard and 1.3 seconds for advanced versions. That’s the secret to our speed machine! Fast cycle time reduction The latest FANUC CNC, Series 31i-Model B Plus, provides you access to our Smart rigid tapping feature: Reduce tapping cycle time by utilising the spindle motor’s maximum output without sacrificing accuracy. For...

Open the catalog to page 6

Features of the ROBODRILL a-DiB Plus series Expanding application rangeExpanding machining area With up to 400 mm Z-axis stroke expansion, ROBODRILL improves the approach to the machining point, white at the same time providing Less interference structure with Large fixtures. Table load capacity 400 kg*1 ROBODRILLs advanced table Load capacity applies to Large fixtures and workpieces for maximum versatility. Available for a wide range of applications, the column can be raised up to 400 mm, depending on fixtures. Servo turret The servo turret features a maximum toot weight of 4 kg, enabling...

Open the catalog to page 7

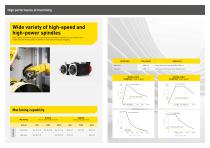

High performance of machining High-rigidity machine structure and optimised combinations of spindle unit and spindle motor enable excellent milling ability in addition to high-speed drilling and tapping. Spindl spec Spindle output 10,000 min-1 (high torque) Spindle output 24,000 min-1 (high speed) Machining capability

Open the catalog to page 8

High performance of machining Maximising uptime Stable machining Thermal displacement compensation Taking the operation status of the spindle and feed axis as a starting point, ROBODRILL estimates the thermal displacement and provides real-time compensation. Moreover, the optional touch probe can automatically adjust the compensation effect from the measurement result. AI thermal displacement compensation II (optional) With the AI option, thermal displacement is estimated even more precisely thanks to temperature sensors around the spindle head and the column. Example of highprecision...

Open the catalog to page 9

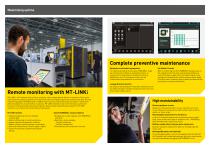

Maximising uptime Complete preventive maintenance Remote monitoring with MT-LINKi MT-LINK; is a PC software that connects machines, robots and peripheral devices in the factory. Data can be collected and visualised to provide more information about manufacturing process and historical data. Not only machines equipped with FANUC CNC or FANUC robots can be connected, but also machines or robots from other manufacturers as well as PLCs or sensors. MT-LINK; software is one of the first steps to utilise IoT functions of manufacturing machines and devices. Based on data collected and presented in...

Open the catalog to page 10

Upgrade for your user experience Favourite screens ROBODRILL now offers you to save frequently used screen setups as favourites in a specific favourites menu. To further enhance versatility, these settings can easily be imported to or exported from other ROBODRILL devices – for maximum usability. Custom screens With the new custom screens feature, you can register up to 15 FANUC PICTURE applications. At the same time, the feature allows for controlling peripheral devices using our custom PMC function, with various exclusive third-party screens available. High usability Operators' panel with...

Open the catalog to page 11

Save time – the smart way ROBODRILL is designed to make work easy and save you time in the process. Thanks to a whole range of smart features, operations are intuitive, setups are managed in no time, and daily maintenance is more convenient than ever. On-board multifunction Ethernet Fast Ethernet function is available for high-speed data transfer to network server etc. Applying various network protocols using Ethernet cable such as FL-net, EtherNet/IP, PROFINET. External interface function General I/O signals such as external start are ready to use only by assigning in the screen....

Open the catalog to page 12All FANUC FRANCE catalogs and technical brochures

-

LR Mate 200iD

1 Pages

-

ROBOSHOT α-SiB series

25 Pages

-

Robots - Product overview

52 Pages

-

M-10 iD/10L (2025)

2 Pages

Archived catalogs

-

R-2000iC/165F

1 Pages

-

M-710iC/20M

1 Pages

-

FIELD system

3 Pages

-

CNC

660 Pages

-

LR Mate 200iD/4SH

1 Pages

-

LR Mate 200iD/7H

1 Pages

-

LR Mate 200iD/7L (

1 Pages

-

ARC Mate 0iB

1 Pages