Catalog excerpts

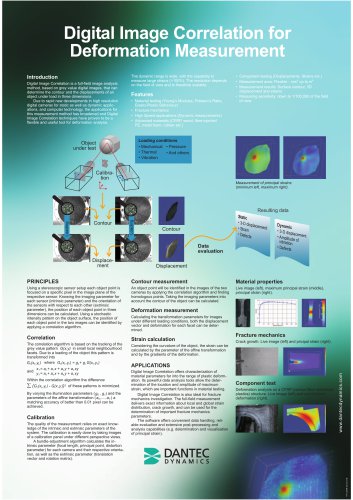

Digital Image Correlation for Deformation Measurement Introduction Digital Image Correlation is a full-field image analysis method, based on grey value digital images, that can determine the contour and the displacements of an object under load in three dimensions. Due to rapid new developments in high resolution digital cameras for static as well as dynamic applications, and computer technology, the applications for this measurement method has broadened and Digital Image Correlation techniques have proven to be a flexible and useful tool for deformation analysis. The dynamic range is wide, with the capability to measure large strains (>100%). The resolution depends on the field of view and is therefore scalable. Features • Material testing (Young’s Modulus, Poisson’s Ratio, Elasto-Plastic Behaviour) • Fracture mechanics • High Speed applications (Dynamic measurements) • Advanced materials (CFRP, wood, fibre injected PE, metal foam, rubber etc.) • Component testing (Displacements, Strains etc.) • Measurement area: Flexible - mm2 up to m2 • Measurement results: Surface contour, 3D displacement and strains • Measuring sensitivity: down to 1/100,000 of the field of view Loading conditions • Mechanical • Pressure • Thermal • And others • Vibration Object under test Measurement of principal strains (minimum left, maximum right). Resulting data Contour Data evaluation Displacement Contour measurement Material properties Using a stereoscopic sensor setup each object point is focused on a specific pixel in the image plane of the respective sensor. Knowing the imaging parameter for each sensor (intrinsic parameter) and the orientation of the sensors with respect to each other (extrinsic parameter), the position of each object point in three dimensions can be calculated. Using a stochastic intensity pattern on the object surface, the position of each object point in the two images can be identified by applying a correlation algorithm. An object point will be identified in the images of the two cameras by applying the correlation algorithm and finding homologous points. Taking the imaging parameters into account the contour of the object can be calculated. Live image (left), maximum principal strain (middle), principal strain (right). Strain calculation The correlation algorithm is based on the tracking of the grey value pattern G(x,y) in small local neighbourhood facets. Due to a loading of the object this pattern is transformed into Gt (xt ,yt ) where Gt (xt ,yt ) = g0 + g1 G(xt ,yt ) Considering the curvature of the object, the strain can be calculated by the parameter of the affine transformation and by the gradients of the deformation. Within the correlation algorithm the difference of these patterns is minimized. Calibration The quality of the measurement relies on exact knowledge of the intrinsic and extrinsic parameters of the system. The calibration is easily done by taking images of a calibration panel under different perspective views. A bundle-adjustment algorithm calculates the intrinsic parameter (focal length, principal point, distortion parameter) for each camera and their respective orientation, as well as the extrinsic parameter (translation vector and rotation matrix). Fracture mechanics Crack growth. Live image (left) and pricipal strain (right). APPLICATIONS Digital Image Correlation offers characterization of material parameters far into the range of plastic deformation. Its powerful data analysis tools allow the determination of the location and amplitude of maximum strain, which are important functions in material testing. Digital Image Correlation is also ideal for fracture mechanics investigation. The full-field measurement delivers exact information about local and global strain distribution, crack growth, and can be used for the determination of important fracture mechanics parameters. The software offers convenient data handling, reliable evaluation and extensive post-processing and analysis capabilities (e.g. determination and visualisation of principal strain). Component test Deformation analysis on a CFRP (carbon fibre reinforced plastics) structure. Live image (left) and out-of-plane deformation (right). Deformation measurement Calculating the transformation parameters for images under different loading conditions, both the displacement vector and deformation for each facet can be determined.

Open the catalog to page 1All Dantec Dynamics catalogs and technical brochures

-

Shearography NDT

1 Pages

-

Particle Image Velocimetry

1 Pages

-

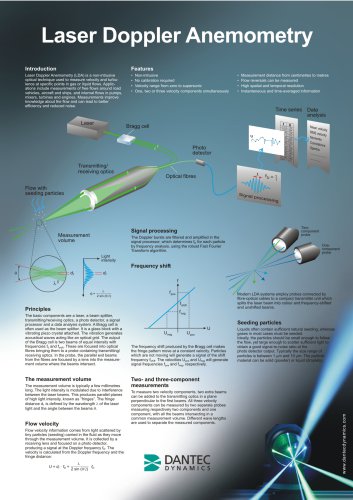

Laser Doppler Anemometry

1 Pages