Catalog excerpts

Supercritical CO2 Cryogenic Cooling System No.6, 2nd Nanyun Road, Science City, Hi-tech Development Zone, Guangzhou, 510663, P.R.C 2024 Conprofe Technology Group Co., Ltd. All Rights Reserved. VE2.6 The information given is not binding. Actual products and mutual agreement shall prevail. Reprinting of any text and illustrations requires written authorization of Conprofe. Professional Manufacturer of Ultrasonic Equipment and High-Performance Tool

Open the catalog to page 1

Manufacturing and Testing Equipment 03 Supercritical CO2 Cryogenic Cooling System 05

Open the catalog to page 2

超声绿色设备及高性能工具专业制造商 About Conprofe About Conprofe With its roots back to 2003, Conprofe is a Provider of Efficient, Green and Intelligent Manufacturing Solutions and Key Units. It has been holding on to the idea of “Converging of Global Resources, Professional as Industry Leader” in the past two decades. Revolving around “Efficient, Green and Intelligent Manufacturing”, the company has achieved a giant leap from parts, units to machines and developed a product portfolio with three major industries - Precision Tools, Key Units and CNC Machine Tools, which covers eight categories of products,...

Open the catalog to page 3

Manufacturing and Testing Equipment 超声绿色设备及高性能工具专业制造商 Supercritical CO 2 Cryogenic Cooling System

Open the catalog to page 4

Supercritical CO2 Cryogenic Cooling System 超声绿色设备及高性能工具专业制造商 Supercritical CO2 Cryogenic Cooling System With the rapid development of modern manufacturing technology, all kinds of new materials and processes came in to Supercritical CO2 Cryogenic Cooling System transforms supercritical CO2 fluid into a low-temperature medium (-78°C) for being, which puts higher requirements for cutting speed, tool life and machining efficiency. Clean production and green cooling and lubrication to the cutting tools. When CO2 at 31°C is pressurized to more than 74bar (1070psi) , it becomes a manufacturing...

Open the catalog to page 5

Product Introduction Supercritical C02 Cryogenic Cooling System » The innovative Supercritical CO2 Cryogenic Cooling Technology adopts a unique system, which transforms the purified low-pressure CO2 collected from petrochemical, steel, food and other industrial manufacturing into supercritical CO2 fluid, and then convert it into a -78OC cryogenic cooling medium for efficient cooling and lubrication. » A special output control system and dedicated nozzle unit ensure continuous and accurate ejection of supercritical CO2 fluid to the cutting area at room temperature. » The fine solid dry ice...

Open the catalog to page 6

Product Introduction Product Introduction Supercritical CO2 Cryogenic Cooling System CEA401 Lubricant Supply Model Dimension (mm) Weight (Kg) Power Supply (V/HZ) Cooling System Dedicated Nozzle Machine Tool Parts Machining Nozzle Positioning » Coaxial Pipe ------ to transport the high-pressure supercritical CO2 fluid and low-pressure auxiliary gas, thus minimizing the heat loss of supercritical fluid and ensuring its performance » The Multi-Channel Nozzle ------ to ensure that there is no condensation, frost and blockage and achieve even and precise ejection » Flexible Output and Control...

Open the catalog to page 7

Product Introduction Product Introduction Advantages of Supercritical C02Cryogenic Cooling System Model CEA401 CIA401 CMA401 Control System Parameter Adjustment Add-On Nozzle 1-3 Nozzles, Separately Control Touch Panel M Code Control Manual Coolant-Through Spindle Single Coolant-Through Spindle Touch Panel M Code Control Add-On Nozzle or Coolant-Through Spindle 1-2 Nozzles, Single Control/ Coolant-Through Spindle PLC Control Touch Panel M Code Control Manual (only for add-on nozzle) » Lower Cutting Temperature------to make high-efficient cooling performance on the machining area by blasting...

Open the catalog to page 8

Application Fields Application Fields The Supercritical CO2 Cryogenic Cooling System features excellent cooling and lubrication performance, especially suitable for turning, milling, drilling or grinding all kinds of hard-to-machine materials. It can be applied in aerospace industry, customer electronics, general precision manufacturing, automotive industry, medical field and others, including aviation engine parts machining, precision shaft parts machining, complex mold machining, auto parts machining and medical surgical instruments machining, etc. » For Stainless Steel » For Titaninum...

Open the catalog to page 9

Application Fields Application Fields Application Cases Workpiece Surface Quality Tool Life of Mills » Workpiece: Cr12Mo1V1, HRC 61 » » Cutting Tool: Carbide End Mill D10,TiAIN » Feed Rate: F=900mm/min Radial Depth of Cut: ae=0.5 mm Axial Depth of Cut: ap=5 mm » Workpiece: SUS316 » Cutting Tool: Carbide End Mill D10,TiAIN » Rotating Speed: S=2000rpm » Feed Rate: F=1000mm/min » Radial Depth of Cut: ae=0.2 mm » Axial Depth of Cut: ap=5mm When the tool wear of dry machining reaches VB=0.3mm, the cycle time of the mill is only 8min. However, the milling time with supercritical CO2 reaches...

Open the catalog to page 10

超声绿色设备及高性能工具专业制造商 Application Fields Application Fields » Workpiece: Mould Steel Cr12Mo1V HRC61 » Cutting Tool: Carbide Mill D10, TiALN » Rotating Speed: S=2000rpm » Feed Rate: F=900mm/min » Axial Depth of Cut: ap=5mm » Radial Depth of Cut: ae=0.5mm Dry Cutting VS Supercritical CO2 Machining Cutting Fluid Machining VS Supercritical CO2 Machining Cuttting Fluid Machining » Feed Rate: F=1500mm/min » Axial Depth of Cut: ap=1mm » Radial Depth of Cut: ae=0.05mm Cutting Fluid Machining VS Supercritical CO2 Machining » Workpiece: PEEK » Cutting Tool: Carbide Mill D6 » Rotating Speed: S=4000rpm »...

Open the catalog to page 11All Conprofe Technology Group Co. catalogs and technical brochures

-

Ultrasonic Machining System

12 Pages

-

PCD Cutting Tools

14 Pages

-

Tapping Tools

38 Pages

-

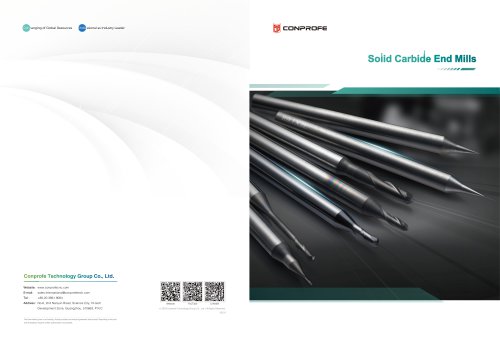

Solid Carbide End Mills

7 Pages

-

Ultrasonic-Green Machine Tools

119 Pages