Catalog excerpts

Superhard Cutting Tools Product Guiding Conprofe Technology Group Co., Ltd. Website: www.conprofecnc.com E-mail: sales-international@conprofetech.com Tel : Address: No.6, 2nd Nanyun Road, Science City, Hi-tech Development Zone, Guangzhou, 510663, P.R.C 2024 Conprofe Technology Group Co., Ltd. All Rights Reserved. VE3.3

Open the catalog to page 1

Manufacturing and Testing Equipment 03 Superhard Cutting Tool Introduction 04 Superhard Material Application Range 05 Solid PCD Micro-Edge Cutting Tools Introduction 07 Solid PCD Micro-Edge Cutting Tools--Application Cases 12

Open the catalog to page 2

Company Overview With its roots back to 2003, Conprofe is a Provider of Efficient, Green and Intelligent Manufacturing Solutions and Key Units. It has been holding on to the idea of "Converging of Global Resources, Professional as Industry Leader" in the past two decades. Revolving around "Efficient, Green and Intelligent Manufacturing" , the company has achieved a giant leap from parts, Con verging of Global Resources units to machines and developed a product portfolio with three major industries - Precision Tools, Key Units and CNC Machine Tools, which covers eight categories of products,...

Open the catalog to page 3

Manufacturing and Testing Equipment Superhard Cutting Tool Based on traditional superhard cutting tools made of diamond and boron nitride, Conprofe independently developed superhard cutting tools series including PCD Micro-Edge Cutting Tools, Welding PCD Cutting Tools, MCD Cutting Tools, PCBN Cutting Tools. Conprofe persistently adheres to unique manufacturing techniques and excellent quality monitoring, winning unanimous praise from many precision manufacturers all over the world. The machining accuracy of superhard cutting tools is able to reach nano level with long tool life. In...

Open the catalog to page 4

Application Range of Superhard Materials PCD Materials Diamond is the hardest and most wear-resistant material known in nature. Synthetic diamond is divided into two types, polycrystal and single crystal, which can be made by chemical vapor deposition (CVD) or high pressure and high temperature (HPHT) method. The polycrystalline composite sheet manufactured by high-temperature and high pressure way is the most common synthetic diamond material, usually abbreviated as PCD. PCD is a kind of diamond composite which is made from 1-30 micrometer diamond powder and catalytic cobalt. The element...

Open the catalog to page 5

Introduction to Solid PCD Micro-edge Cutting Tools SeriesSolid PCD Micro-Edge Cutting Tools Standard Series > Solid PCD Micro-Edge Ball End Mill Solid PCD Micro-Edge Bull Nose End Mill Specification Chart Blade Diameter(D) R Angle (R) Effective Blade Length (hi) Tool Holder Diameter (d) Specification Chart Unit:mm

Open the catalog to page 6

> Solid PCD Micro-Edge Flat End Cutter > Solid PCD Micro-Edge Spherical Cap Bull Nose End Mill Specification Chart Unit:mm Blade Diameter(D) Effective Blade Length (h1) Tool Holder Diameter (d) Specification Chart Unit:mm Blade Diameter(D) R Angle (R1) Effective Blade Length (h1) Tool Holder Diameter (d)

Open the catalog to page 7

Gyroscope Machining Machining Case of Solid PCD Micro-Edge Cutting Tool Specification Chart Material: Quartz Glass Dimension: 20*20*15.5mm Wall Thickness: 0.7mm Advantages: No chippings, cracks and the shorter depth of subsurface damage layer Cutting Tool ® Ultrasonic Machining System+Solid PCD Micro-Edge Cutting Tools

Open the catalog to page 8

Carbon Fiber Hole MachiningApplication Case of Solid PCD DrillCarbon Fiber MillingApplication Case of Solid PCD Micro-Edge Cutting Tool 13 ® Ultrasonic Machining System + Solid PCD Drill ® Solid PCD Micro-Edge Cutting Tool Traditional Machining • Severe tool wear and short tool life • Severe burring with high scrap rate Ultrasonic System + Solid PCD Drill • Smooth and neat holes; no tearing, delamination, burring and softening • Significantly reduce burrs around holes • Hole quality improved by 3 times Blind Grooving Cavity Machining Solid PCD Micro-Edge Cutting Tool • Slight burrs in...

Open the catalog to page 9

SuperalloyApplication Case of PCD Micro-Edge Cutting Tool Deep Mircro-Hole Machining of Sintered CeramicsApplication Case of Solid PCD Drill ® Ultrasonic Machining System + Solid PCD Drill Solid PCD Micro-Edge Cutting Tool Solid PCD Micro-Edge Cutting Tool Superalloy with Mirror-Finish Effect • Depth diameter ratio of deep micro hole is 6:1 • The hardness of sintered ceramics is as high With ultrasonic machining, the cycle time of the D1*6 Solid PCD reached 750 holes/pcs

Open the catalog to page 10

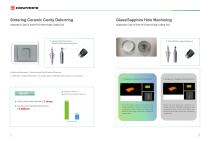

Sintering Ceramic Cavity Deburring Glass/Sapphire Hole Machining Application Case of Solid PCD Micro-Edge Cutting Tool Application Case of Solid PCD Micro-Edge Cutting Tool Ultrasonic Machining System + Solid PCD Micro-Edge Cutting Tools Solid PCD Micro-Edge Cutting Tools Machining Requirement - Ceramic Internal Cavity FInishing & Deburring Challenges in Traditional Machining - Low surface quality and efficiency with extra time on re-machining Roughness of Glass Hole Wall Sa 69nm Traditional Cutting Tool Benefit Cavity surface quality improved by 3 Roughness of Sapphire Hole Wall Sa 81nm...

Open the catalog to page 11

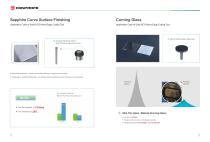

Sapphire Curve Surface FinishingApplication Case of Solid PCD Micro-Edge Cutting ToolCorning GlassApplication Case of Solid PCD Micro-Edge Cutting Tool ® Solid PCD Micro-Edge Cutting Tools • Machining requirement - Contour and surface finishing on sapphire curve surface • Challenges in Traditional Machining - Low surface quality and efficiency with extra time on re-machining ■ Traditional Cutting Tool ■ Solid PCD Micro-Edge Cutting Tool • Tool life increased by 2 times• C/T decreased by 35% Tool Life C/T ® Ultra Thin Glass - Material (Corning Glass) • No tool mark and crack on workpiece...

Open the catalog to page 12

Glass front cover cavity finishing Silicon Carbide Ceramic Application Case of Solid PCD Micro-Edge Cutting Tool Application Case of Solid PCD Micro-Edge Cutting Tool Silicon Carbide Ceramic Solid PCD Micro-Edge Cutting Tools Solid PCD Micro-Edge Cutting Tools Machining requirement - Contour and surface finish machining on Glass front cover inner cavity Challenges in Traditional Machining - Low surface quality and efficiency with extra time on re-machining Traditional Cutting Tool Benefit Tool life increased by 9 Solid PCD Micro-Edge Cutting Tool Surface quality increased by 3 Tool Life...

Open the catalog to page 13All Conprofe Technology Group Co. catalogs and technical brochures

-

Ultrasonic Machining System

12 Pages

-

Tapping Tools

38 Pages

-

Solid Carbide End Mills

7 Pages

-

Ultrasonic-Green Machine Tools

119 Pages