Catalog excerpts

Seconds ahead 15 Series Fast and powerful precision machining centers for profitable production - with one, two or four spindles Designed and Made in Germany www.chiron.de

Open the catalog to page 1

Leading-edge technology offering high reliability, performance and precision CHIRON 15 series vertical machining centers are among the best machine tools in their class in terms of speed, dynamics, compact construction, stability and reliability. With ample power for great milling capacity, the CHIRON 15 series can be supplied as single, double, four-spindle or multi-profile versions, and are characterized by: I Reliably high productivity I Highest precision and processing quality I Reduced space requirements I Fast set-up I Simple operation I High stability I High dynamics I Easy...

Open the catalog to page 2

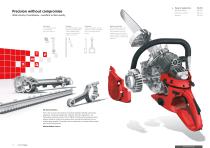

Precision without compromise Machine design Extension options Wide variety of workpieces – excellent surface quality Aerospace An example of 4-sided complete machining of extruded profiles with the CHIRON FZ15 MP, aluminum structured profile [1,600 mm x 75 mm] Automotive Lowest cost-per-piece, complete machining of vehicle components such as: connecting rods and cylinders Machine construction Milling, drilling, threading and turning in a single set-up, e.g. 5-axis complete machining of integral components for motor saws (casing parts of magnesium), cylinders, pistons, connecting rods,...

Open the catalog to page 3

Versatility through high-tech modules Machine design Extension options Perfectly suited to any application Spindles & spindle systems: FZ: Proven single-spindle machining center in a vertical traveling column design DZ: Highly productive double-spindle machining centers with a spindle clearance of 250, 320 or 400 mm TZ: Highly productive four-spindle machining centers with a spindle clearance of 3 x 200 mm FZ15 W Compact, fast single-spindle machining center with integrated basket tool changer and integrated workpiece changing device 0°/180° for easy loading and unloading during machining....

Open the catalog to page 4

Proven modules for customized configurations Flexible work areas _ and maximum paths: Spindles & spindle systems Automatic tool changer Table options Process advantages: I Maximum path [X-Y-Z] I Maximum power I Spindles / clearance DZ I Spindles / clearance TZ I Maximum spindle speed I Chip-to-chip time I Axis acceleration X-Y-Z max. I Rapid feed as fast as I Max. number of tools I Tool taper I Maximum tool weight I Maximum tool diameter I Max. tool length I Automatic workpiece change Highly productive double-spindle machining center with a fast basket tool changer (2 x 12 tool places)...

Open the catalog to page 5

Machine design Extension options Reliable technology and high precision as a foundation The workpiece changing device is equipped with a central distribution for power supply lines and provides ample space for various devices or NC rotary table assemblies. Downtimes are greatly reduced due to loading and unloading during machining. FZ15 S Flexible precision machining center with the fast basket tool changer The fixed table provides ample space for various devices or NC rotary table assemblies. FZ15 W Fast precision machining center with automatic pick-up tool changer and workpiece changing...

Open the catalog to page 6

Extension options Precision and dynamics at the highest level Machine design Complete machining with CHIRON Five axis FZ15 FX Fast precision machining center with the fast CHIRON basket tool changer and a 2-axis swivel rotary table. High productivity, with chip-to-chip times as short as 1.7 seconds and tool changing times from 0.9 seconds. DZ15 FX Doubled productivity with minimal space requirements: fast double-spindle machining center with a 2-axis swivel rotary table with two face plates for efficient complete machining with five simultaneously controlled axes. Five-axis machining with...

Open the catalog to page 7

Machine design Extension options Increase profits with 2 or 4 spindles The multiplier effect – more spindles, more cutting, more profit: Doubled productivity on one machine means a reduction in machining time of nearly 50%. There is also the option of multi-sided machining using an NC-controlled rotary axis. Fast, double-spindle machining center with basket tool changer and a 2-axis swivel rotary table with two face plates for economical 5-axis complete machining. DZ15 W The combination of two spindles and a fixed table, or workpiece changing device 0°/180°, as well as a quadruple clamping...

Open the catalog to page 8

Range of applications Machine design Extension options Services Multifunctional machining center for the complete machining of workpieces of different lengths from extruded profiles of any type. Milling, drilling, threading, countersinking, reaming or separating - anything is possible, regardless of whether series parts or variants are being machined. Your advantages with CHIRON MP: I Automatic production of consecutive workpieces I Profile sizes up to 150 x 150 mm I Lower costs per unit due to high productivity of the process I Spindle speeds up to 20,000 rpm I High production quality by...

Open the catalog to page 9

Automatically a step further Machine design Extension options Flexible automation solutions for more production time Variocell SYSTEM – Customized automation solutions: I Machine-integrated spindle grippers I Portal and articulated-arm solutions I Load and unload devices I Pallet changing systems I Pallet storage for raw and finished parts I Interlinked systems and much more A flexible and cost-effective solution with a compact unit consisting of a machining center, a handling robot and a workpiece storage system for virtually unmanned operation and high process safety. Pallet storage for...

Open the catalog to page 10

Options for your production Machine design Extension options individualized to meet your specific requirements CHIRON laser control for tool breakage checks, for tool measurement and for machine compensation. Internal cooling via the spindle up to 70 bar; also available with a frequencycontrolled pump. Stationary 3D probing system TS 27 for tool length measurement, tool breakage checks as well as machine compensation. Workpiece gripper in the main spindle for machine-integrated workpiece handling. Series 15 – further options: I High Speed Plus package I Reinforced spindle drive I Work area...

Open the catalog to page 11All CHIRON-WERKE GMBH & CO.KG catalogs and technical brochures

-

Série 08

13 Pages

-

BASELINE-2016

4 Pages

-

BR12

11 Pages

-

MILL Series

11 Pages

-

24 Series

11 Pages

-

18 Series

11 Pages