Catalog excerpts

BÖHLER – ONE SOURCE – FROM THE MELT TO THE FINISHED PRODUCT Forging specialists are at work in BÖHLER’s open die forge. Here is where metallurgical expertise, over 100 years of experience in special steels and a passion for precise machining come together. The result: high-precision components made from materials we tested and developed. The integrated manufacturing process – from melt to finished product – offers the possibility of developing new materials for specific applications and guarantees high quality and safety standards. The advantages for our customers are also apparent in our...

Open the catalog to page 2

OUR STRENGTH – YOUR ADVANTAGE

Open the catalog to page 3

YOUR MARKET – OUR SEGMENT: ENERGY For tomorrow’s energy Typical products for energy applications Meeting today’s energy demand while at the same time being sensitive to the needs of the environment is one of the challenges we face today. Energy-efficient and cost-effective turbines – gas, steam or hydro-powered – form the basis of environmentally friendly and economical energy production. Compressor and turbine discs, compressor components, high pressure and intermediate pressure rotors, monobloc rotors, shaft ends, hollow shafts, housing components, coolant pump parts, valve and pump...

Open the catalog to page 4

The chemistry of life The exploration and extraction of fossil fuels from the bottom of our oceans, the manufacture of plastics or the processing of drinking-water have become common place. Only when these services are disrupted do we notice the extent of our reliance on them. Therefore it is important to offer materials specially designed for highly corrosive environments and extreme mechanical stresses to the industry. Typical products Components for mooring systems (swivels), valve bodies, tubing hangers, hollow bars, hollow shafts, y-pieces, components for centrifugal separators,...

Open the catalog to page 8

Safety accepts no compromise Manufacturing components for aviation and space programs requires the highest technological standards, strict quality management setup and a great deal of responsibility from the people involved in order to meet the requirements of the world‘s most significant manufacturers of aircraft engines. Typical products Helicopter rotor shafts, turbine shafts, stub shafts, casing and cover turbine pump starters (Ariane V), drive train shafts, pancake discs for prototyping.

Open the catalog to page 10

HIGH FLYING MATERIALS

Open the catalog to page 11

YOUR MARKET – OUR SEGMENT: EXTRUSION Complex solutions Typical products BÖHLER is the world leader in tool steel manufacturing and research. This experience is incorporated into our extrusion products. With highly sophisticated FEM analysis tools we simulate your process conditions to provide the right solutions. Fully equipped containers, mantles, liners, stems, refitting services. BÖHLER grade Industry Specifications

Open the catalog to page 12

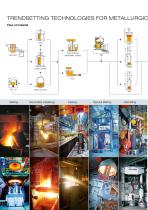

TRENDSETTING TECHNOLOGIES FOR METALLURGIC Flow of material Ingot Casting (electrodes, ingots) Ladle Furnace Secondary metallurgy Special Melting

Open the catalog to page 14

Rotary Forging Machine Multiline Rolling Mill Cogging Mill Heat Treatment

Open the catalog to page 15

Production facilities - Machining Turning 1. Five CNC vertical turning and boring lathes: max. 0 2,900 x 1,900 mm 2. Two CNC horizontal lathes without tailstock: max. 0 1,000 x 400 mm 3. Four small/medium CNC horizontal lathes (one with milling device) max. 0 1,000 x 6,000 mm resp. 0 700 x 10,000 mm 4. Five large CNC horizontal lathes (one with milling device) max. 0 2,000 x 12,000 mm Components for steam and gas turbines (discs, rings, hollow shafts, rotors, housings), components for nuclear, extrusion, oil & gas and aviation applications Boring, milling One CNC milling and drilling...

Open the catalog to page 17

ULTIMATIVE FORGING 52 MN press Rotary forging machine The heart of the open die forge is our 5200 t forging press, where materials are shaped to meet exact customer demands. Forged pieces are used whenever the requirements for the mechanical properties of certain components are high. With this most modern and unique production line, BÖHLER is venturing into a new dimension of forged bars and open die forgings. We at BÖHLER are well aware of these requirements and offer you custom-made open die forgings or round and flat steel bars in high alloyed materials. Piece weight from 3 to 30 tons...

Open the catalog to page 18

SUPERLATIVE MACHINING From rough maching to aerospace – as you like it The machine shop, the highlight at the end of the production chain. Here is where all of the production steps come together to be matched to your individual requirements. This guarantees the full quality control cycle from a single source. The forged parts are rough machined on state-of-the-art CNC milling, drilling and turning machines in accordance with the specifications and drawings.

Open the catalog to page 20

Some of our system and material approvals All of the planning, testing and productions steps involved in the manufacturing of forged billets are, of course, included in our Quality Assurance System. We have been certified by numerous national and international inspection bodies in accordance with various national and international standards such as ISO 9001, EN 9100. We make sure you can rely on our products. Quality is an obligation to us. Material approvals Institution Certificates VdTUV WB 508 VdTUV HD-AGA System approvals Institution Certificates

Open the catalog to page 24

GAZm Wftnrtwln Deutschen Akkreditier # Akkreditieru D* GAZ G**rtKf«h Eh MAiock*ri*v ini 0*l/uw LHb<nlprtwi riw BotiNr H jiiUMflRBiialU ft, Htfii tfafrtnr ■n Sm, Sbr^kfl Mg&SMll aHHu 25. BW5 K DIN EN iSG-iEC 1 TOM-2005 teninm ihiduigtn in1 - » Pnif&bori*wi«n !fr l fiKNni^iidwUI Uit'rtiT.ua* u>.] an Mr Ulan unS Lsg«snri30n. VW UnxAota WfcTftftar*idkjnyen i‘ TnchinirajnKhi *T«jo»na«i oh> PrZftais tas Um-iwf***- i'pm1 «*.■ a. MMttflf ?pc i 4. ftvnggta AraMjPM *Vt 3 SMii WOO maitaiOp^dd'B iKAvrai^pfi C-inHiii physANtota rn Afa!.’*-=ii:Wa&w wjn-jKru-Jw YVifcijngv i«J JJtofewwigreClin. 6. !...

Open the catalog to page 25

RESEARCH It is the mind that controls the body Today, to a certain degree, it is possible to design new materials at the computer. A quantum leap. Targeted use of simulation programmes allows complex alloying systems to be captured numerically and to predict the phases which will appear, their composition and their volume fractions. This leads to a better understanding of the materials and also reduces laboratory time and costs during development. In this way, materials and tailor-made properties can be designed. State-of-the-art facilities allow materials properties to be measured which...

Open the catalog to page 26All BÖHLER EDELSTAHL GMBH & CO.KG catalogs and technical brochures

-

V300

1 Pages

-

V124SC

1 Pages

-

V118S1

1 Pages

-

N360

1 Pages

-

N352S1

1 Pages

-

N352

1 Pages

-

E108

1 Pages

-

A750

4 Pages

-

V140

1 Pages

-

V126

1 Pages

-

N709

1 Pages

-

N701

1 Pages

-

T671SB

1 Pages

-

T671SA

1 Pages

-

T200SA

1 Pages

-

T200

2 Pages

-

N700

8 Pages

-

N695

2 Pages

-

L090

1 Pages

-

SPECIAL AEROSPACE MATERIALS

16 Pages

-

PLASTIC MOULD STEELS

20 Pages

-

M121 ISOPLAST

12 Pages

-

BW137DE_Power_Generation.

20 Pages

-

SC128_Semi-finished products

16 Pages