Catalog excerpts

WHO WE ARE BeAM, an AddUp Company, is a pioneer in designing and BeAM works closely with customers to develop and industrialize new methods of manufacturing parts using DED to eliminate many challenges faced with traditional manufacturing,

Open the catalog to page 2

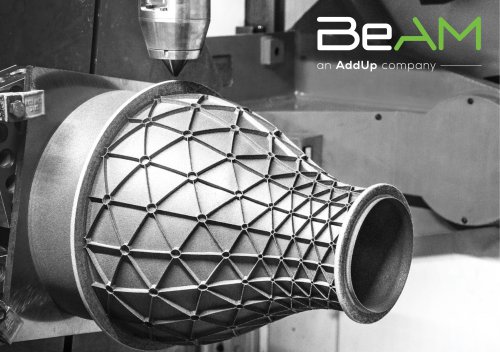

DIRECTED ENERGY DEPOSITION (DED) DED, also known as LMD, is an Additive Manufacturing process where focused thermal energy is used to fuse materials by melting them as they are deposited, BeAM's process involves converging metallic powderthrough our nozzle to the focal point ofthe laser, creating a melt-pool laid down in a 5-axis configuration, This allows continuous freedom to build/repair components layer by layer withoutthe need for support structures, Utilizing traditional numerical controls and using ISO G-code gives our customers tools that their skilled workforce is already...

Open the catalog to page 4

DED APPLICATIONS Reduce material waste on small and large parts Complex geometries Print less, machine less

Open the catalog to page 5

ADDITION OF FEATURESADD TO EXISTING PARTS REDUCE MACHINING TIME 6

Open the catalog to page 7

STVEMTTERITLAOOREOUCEBUY-TO-FLYRTTIO FROM 9:lTO 2:1 • Better repeatability than with manual welding processes • Work under controlled atmosphere to ensure mah material quality & safety • Reduce machining cost - Easily fits in the manufacturing chain AEROSPACE FLANGE

Open the catalog to page 8

Our range of industrial coaxial deposition nozzles offer precise, different deposition width powered by high quality fiber laser sources of 500 Wto 2 kW anaa dual gas flow.

Open the catalog to page 10

INDUSTRIAL | PRODUCTION READY | HIGH PERFORMANCE 5-Axis machines with Siemens 840D control 1 Operated by|SO GCode Controlled atmosphere | BeAM Nozzles | Touch Probe1 Me|t-p°o1 Monitoring

Open the catalog to page 11

R&D - SMALL PARTS I COMPACT I ECONOMICAL Build volume: 400 x250x300mm 500Wfiber laser 10Vx deposition head Powderfeeder with up to 2 hoppers of 1.5L

Open the catalog to page 12

MODULO 400 VERSATILE | PORTABLE | UPGRADABLE Build volume: 650 x400 x400mm 500Wto 2kW fiber laser l0Vx/24Vx deposition heads Powderfeeder with up to 5 hoppers of1.5L

Open the catalog to page 13

FLAGSHIP | LARGE CAPACITY | ADAPTABLE Build volume: 1200 x 800 x800mm 500Wto 2kWfiber laser 10Vx/24Vx deposition heads Powderfeeder with up to 5 hoppers of 1.5L

Open the catalog to page 14

AACHEN CENTER FOR ADDITIVE MANUFACTURING SOME CUSTOMERS RUDN university OPEN INNOVATION We collaborate with R&D centres and universities to maintain ourtechnological lead, We also offer knowledge transferto partners that wish to become regional DED experts, With the support of Grand l-st ALSACE CH AMPACNE-AROENNE LORRAINE

Open the catalog to page 15All BEAM - FIVES catalogs and technical brochures

-

BeAM Catalogue 2018

16 Pages

-

MOBILE

2 Pages