Catalog excerpts

General Industry DOUBLE DIAPHRAGM PUMPS LOW PRESSURE DDP 120 B DDP 120 B.TE (Aluminium) DDP 120 BN.TE (Stainless Steel) DDP 120 B WB.TE (Anodized Aluminium) DPS 120 C DPS 120 C.TE (Aluminium) DPS 120 CN.TE (Stainless Steel) DPS 120 C WB.TE (Anodized Aluminium) DDP 90 E DDP 90 F.TE (Aluminium) DDP 90 FN.TE (Stainless Steel) DDP 90 F WB.TE (Anodized Aluminium) DPS 90 G DPS 90 G.TE (Aluminium) DPS 90 GN.TE (Stainless Steel) DPS 90 G WB.TE (Anodized Aluminium) USER’S INSTRUCTION MANUAL

Open the catalog to page 1

DIAPHRAGM PUMPS Dear Customer, We thank you for the preference you gave us and we are glad to count you among our customers. We hope the use of this equipment will satisfy you and your staff. IMPORTANT This use and maintenance manual is an integral part of the equipment and must be easily available to the staff in charge of its use and maintenance. The user and the personnel in charge of maintenance must be aware of the contents of this manual. Read the manual carefully before starting ANY ACTIVITY involving the equipment, including its handling. For easier references the instruction manual...

Open the catalog to page 2

DIAPHRAGM PUMPS BE CAREFUL ABOUT VENTILATION USE IT IN A WELL-VENTILATED AREA. Painting or cleaning in a narrow area with insufficient ventilation can cause organic solvent intoxication or explosion due to sprayed mist of paint or solvent which catches fire. If you feel any abnormality during operation, consult a medical doctor immediately. DIAPHRAGM PUMPS 4. TRANSPORT AND HANDLING To transport the equipment only the systems described below can be used. In any case make sure that the transport and lifting device can bear the weight of the equipment with its packaging. ALWAYS KEEP THE...

Open the catalog to page 3

DIAPHRAGM PUMPS *CART SET AXLE “U” BOLT _ HEX. NUT SNAP PIN WASHERS SOLID TIRES HANDLE HEX. NUT (M8) BOLT WITH HEX. HOLE (M8) HEX. NUT (M6) BOLT WITH HEX. HOLE (M6) Pump Unit **HOPPER SET HOPPER “U” HOSE 5. PRODUCT IDENTIFICATION 5.1 PLATE DATA The manufacturer’s identification plate is applied on the diaphragm pump (see picture below). It must not be removed at all, even if the equipment is resold. For any communication with the manufacturer always mention the serial number written on the plate itself. PUMP TYPE All the units are conceived in compliance with the applicable Essential Safety...

Open the catalog to page 4

• PR-5BL paint regulator for DPS 120-1C.TE and DPS 90-1G.TE • PR-5BLN paint regulator for DPS 120-1CN.TE and DPS 90-1GN.TE • PR-5BL WB paint regulator for DPS 120-1C-WB.TE and DPS 90-1G-WB.TE UNIT ASSEMBLY STAND TYPE TANK MOUNT TYPE WALL MOUNT TYPE DDP version mounted on Tank mount lid (without tank) with paint regulator, 2 air regulators (for pump and gun), paint filter unit, dip pipe with filter (for 20L tank), fluid recirculation, overpressure valve, ball valve with exhaust hole. CART TYPE w/ HOPPER 6 lt. • PR-5BL paint regulator for DPS 120-2C.TE and DPS 90-2G.TE • PR-5BLN paint...

Open the catalog to page 5

DIAPHRAGM PUMPS 6.5 WORKABLE PRODUCTS Models DPS-120C.TE and DPS-90G.TE are designed for paints with a maximum viscosity of 85 sec/Ford #4 (100 sec/NK-2). We don’t recommend the use of these models with water-based paints. Models DPS-120CN.TE/C-WB.TE and DPS-90GN.TE/G-WB.TE are intended also for water-based paints. The Company ANEST IWATA is not to be held responsible for any accident due to the pump use by an UNAUTHORIZED and non qualified staff using it for purposes that are different from the above mentioned ones. The installer must know the ATEX classification of the installation area,...

Open the catalog to page 6

A - STAND TYPE AND CART TYPE Remove the dust proof caps (B,E,F,H,I on page 15) Detach the pump assembly from the support by removing Hex. Bolts (M8). Flip the stand and assemble the pump assy to the right position. COMMON 1. Connect the drain hose to the 2-way valve for paint recirculation. DIAPHRAGM PUMPS CART TYPE Assemble the following parts below in numerical order, and fix them to the stand. *Put the end of the pin into axle hole, and push it inside all the way by using hammer. Drain hose Unscrew from pump lower adaptor the fitting bolt (M8) and assemble the handle on stand by using...

Open the catalog to page 7

DIAPHRAGM PUMPS DIAPHRAGM PUMPS 3. Open the two-way valve for paint recirculation (Ref. B on page 15). This section describes the diaphragm pump use in compliance with the safety standards in force. Read this section carefully. 4. Lift and turn gradually the pressure reducer knob (Ref. C on page 15). Adjust it at a pressure slightly higher than 2.0 bar, to enable the pump to release the air. 8.1 SAFETY RULES DURING USE 5. Close the two-way valve for paint recirculation (Ref. B on page 15) and release the air through the gun, too. • TO USE the diaphragm pump COMPLY WITH the safety...

Open the catalog to page 8

DIAPHRAGM PUMPS WARNING IF SOME SPARKS OR AN ELECTRIC DISCHARGE WERE PERCEIVED, INTERRUPT IMMEDIATELY ALL PAINTING OPERATIONS. DO NOT USE THE SYSTEM UNTIL THE PROBLEM CAUSE IS IDENTIFIED. Keep away from the working area all kinds of waste, of solvent container, of solvent or petrol soaked rags or clothes. Do not smoke inside the working area. During painting operations, or if there are some vapours in the air, do not switch on or off the lights inside the working area. Do not use any petrol engine inside the working area. 9.3 RECOMMENDED SCHEDULED OPERATIONS EVERY 50 HOURS WORKING HOURS...

Open the catalog to page 9

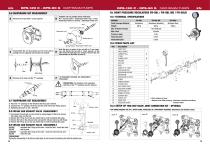

DIAPHRAGM PUMPS Remove the 2 nuts with a 13 mm spanner. REMOVE THE FOLLOWING PARTS FROM ROD: Nut - Spring washer - Diaphragm holder (out) - O’ring Diaphragm holder set (in/out) - Diaphragm holder (in) Aluminium Anodized Stainless Steel Pressure range Diaphragm (in) Nut Hold flat face of center of the rod with a 12 mm spanner, and loosen the nut with a 13mm spanner on the side where the diphragm has not been removed yet and disassemble as described in point B). Remove the O rings and the “Y” packings. TO REASSEMBLE REVERSE THE DISASSEMBLY PROCEDURE. PRECAUTION: Pay attention to the assembly...

Open the catalog to page 10

DIAPHRAGM PUMPS DIAPHRAGM PUMPS 10.4 TWO-WAY VALVE JOINT CONNECTION KIT - OPTIONAL Ref. Description for ALUMINIUM TYPE 1 PAINT REGULATOR 2 JOINT 3 T-JOINT 4 ELBOW UNION for STAINLESS STEEL TYPE 1 PAINT REGULATOR 2 JOINT 3 T-JOINT 5 STREET UNION 6 UNION JOINT M-F for ALL TYPES 7 SUB PLATE 8 BOLT WITH HEX. HOLE 9 PLATE 10 PRESSURE GAUGE 11 ELBOW UNION 12 TUBE 14 AIR REGULATOR 15 ELBOW 16 T-JOINT 17 UNION JOINT M-F ALUMINIUM TYPE Pay attention to tightening torque when fitting joint (ref.1). Too much tightening can damage main body. Tightening torque of joint 14.7 N-m When fitting joint, pay...

Open the catalog to page 11All ANEST-IWATA FRANCE catalogs and technical brochures

-

W 400

24 Pages

-

PET-N series

27 Pages

-

TOF-5B/TOF-6B

16 Pages

-

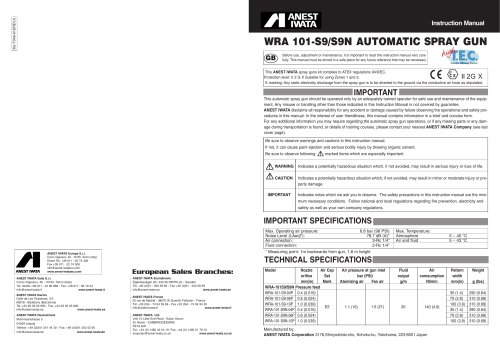

WRA-101

4 Pages

-

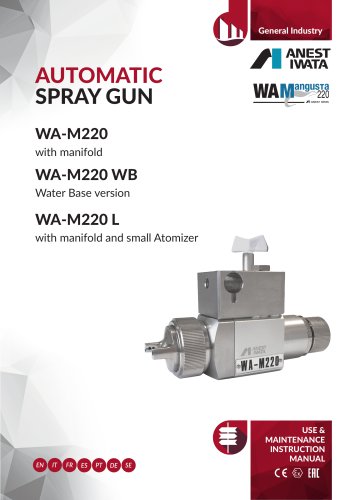

WA-M 220

32 Pages

-

ws 400/ls 400

24 Pages

-

EXTERNAL CHARGE

6 Pages

-

W300 WB Retouch Spray Gun

1 Pages

-

W200 Manual Spray Gun

1 Pages

-

LPH 80

1 Pages

-

W400 WBX

1 Pages