Catalog excerpts

Rotary Torque Transducer Rotary Torque Transducer Digital SGRSl0/520 series Torque Transducer Torqsense Digital rotary strain gauge series (SGR) Transducers use non contact technology eliminating the need for noisy slip rings. They are suitable for torque measuring, testing, feedback control of drive mechanisms and process control applications. The SGR series transducers use modern strain gauge signal conditioning techniques to provide a high bandwidth low cost torque measuring solution with high overrange and overload capabilities. FEATURES Transducers from 1Nm to 13000 Nm. Large fully functional overrange capability of 250% (SGR 520) Minimal side and end load errors Low linearity deviation of ± 0.05 % FSD Low hysteresis error of ± 0.05 % FSD Zero variation in torque signal with rotation (cyclic variation) Non contact signal transmission, no slip rings to wear out High digital sample rate of 4000 samples per second Adjustable torque data smoothness, low pass filter (SGR520) Speed measurement / Power computation Wide power supply range 12-32 VDC Compatible with ethernet gateway module Fixed voltage or current analog outputs (one for torque and the other for speed or power) for interfacing with analog instrumentation BIT Self-diagnostics for letting the manufacturer know that the transducer‘s torque, speed ratings and calibration due date have not been exceeded. Simple ‚Sensor status‘ output pin Sensors to monitor shaft temperature for better compensation and accuracy Whereas, TorqSense SGR520 series transducers offer: Digital outputs, such as RS232, CANbus and USB, for interfacing with modern instrumentation and laptops Digital input for configuring transducer via PC 2 x user selectable voltage or current analog outputs (one for torque and the other for speed, power or peak torque) for interfacing with analog instrumentation Transducer configuration software to allow user to change transducer variables BIT Self-diagnostics for letting users know data is trustworthy, that the transducer‘s torque, speed ratings and calibration due date have not been exceeded Simple ‚Sensor status‘ output pin Sensors to monitor shaft temperature for better compensation and accuracy Ability to connect up to 10 transducers using USB Optional external ethernet gateway module

Open the catalog to page 1

Rotary Torque Transducer TECHNOLOGY The SGR series torque transducers use a full four element strain gauge bridge to measure the torsion present on a shaft. The full bridge helps to diminish errors from any offaxis forces that are sometimes unintentionally applied to the transducer in some test setups. The full bridge also increases the sensitivity and the temperature performance of strain measurement. A rotor mounted ultra-miniature microcontroller measures the strain gauge bridge and transfers the information back to the stator digitally eliminating any noise pickup usually associated...

Open the catalog to page 2

Rotary Torque Transducer

Open the catalog to page 3

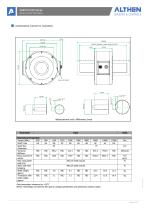

Rotary Torque Transducer 145.00 (Option P, pl ai n shaft 180.00) 120.00 (Option P, plain shaft 144.00 ) Measurement units: Millimetres (mm) Mechanical Properties Torque (Max) 1 Shaft Code CF Shaft Size 6 (Diameter) Torsional 0.23 Stiffness Mass moment of 0.45 inertia, LV Max measurable load limit Static safe load breaking Shaft weight, 0.03 approx Transducer with 0.7 shaft weight, approx Data parameters measured at +20°C Sensor Technology Ltd reserves the right to change specification and dimensions without notice.

Open the catalog to page 4

Rotary Torque Transducer 190.00 (Option P, plain shaft 230.00) Measurement units: Millimetres (mm) Parameter Mechanical Properties Torque (Max) Shaft Code Shaft Size (Diameter) Torsional stiffness Mass moment of inertia Max measurable load limit Static safe load breaking Shaft weight, approx Transducer with shaft weight, approx Data parameters measured at +20°C Sensor Technology Ltd reserves the right to change specification and dimensions without notice.

Open the catalog to page 5

Rotary Torque Transducer 250.00 (Option P, plain shaft 270.00) Measurement units: Millimetres (mm) Mechanical Properties Torque (Max) 650 Shaft Code GE Shaft Size (Diameter) Torsional TBC Stiffness Mass moment of TBC inertia Max measurable load limit Static safe load breaking Shaft weight, TBC approx Transducer with TBC shaft weight, approx Data parameters measured at +20°C Sensor Technology Ltd reserves the right to change specification and dimensions without notice.

Open the catalog to page 6

Rotary Torque Transducer STANDARD RANGE – Optional feature Torque, Speed, Power Outputs Torque only Torque & Speed (60 pulses/rev) Torque & Speed (360 pulses/rev) Torque & Power (60 pulses/rev) Torque & Speed (60 pulses/rev) or Power Torque & Speed (360 pulses/rev) or Power Standard features Keyed Shaft Ends Voltage output ±5v FSD (Fixed) Voltage outputs from ±1v to ±10v FSD and unipolar (Variable) USB 2.0 full speed 12 Mbps Digital output RS232 output Torque Averaging and Torque Peak Self Diagnostics Internal temperature measurement Deep grooved shielded bearings with oil lubrication...

Open the catalog to page 7

Rotary Torque Transducer CONNECTOR AND LEAD OPTIONS Connectors & Leads Analog Connector Digital Connector For user to self wire For user to self wire 12 Pin Lumberg (female) to 15 way ‘D’ type connector (female) For connecting SGR to user’s system via 15 pin ‘D’ connector 12 Pin Lumberg (male) to 15 way ‘D’ type connector (male) For connecting SGR to user’s system via 15 pin ‘D’ connector Analog Lead (Length 2.5m) Digital Lead (Length 2.5m) Digital Lead Adapter (Length 1m) 15 Way ‘D’ type (female) to RS232 and Power Connectors DigitalL ead Adapter (Length 1m) 15 Way ‘D’ type (female) to...

Open the catalog to page 8

Rotary Torque Transducer ADDITIONAL RELATED PRODUCTS GLOSSARY OF TERMS AND DEFINITIONS USED IN THIS DATASHEET

Open the catalog to page 9

Rotary Torque Transducer Page 10 / 10 The information provided herein is to the best of our knowledge true and accurate, it is provided for guidance only. All specifications are subject to change without prior notification. Althen – Your expert partner in Sensors & Controls | althensensors.com Althen stands for pioneering measurement and custom sensor solutions. In addition we offer services such as calibration, design & engineering, training and renting of measurement equipment. Germany/Austria/Switzerland info@althen.de Benelux sales@althen.nl France info@althensensors.fr Sweden...

Open the catalog to page 10All Althen Sensors & Controls catalogs and technical brochures

-

GLET SERIES

18 Pages

-

GLET-10xB530AH(T)-Bi12-Bi5

1 Pages

-

PetitLOGGER GL100 SERIE

2 Pages

-

GL7000

6 Pages